Programming and Operating Manual (Milling)

210 6FC5398-4DP10-0BA6, 09/2017

Using MID and the total depth, the cycle automatically calculates this infeed which lies between 0.5 x maximum infeed depth

and the maximum infeed depth. The minimum possible number of infeed steps is used as the basis. MID=0 means that the

cut to pocket depth is made with one feed.

The depth infeed starts from the reference plane brought forward by the safety clearance (depending on _ZSD[1]).

FFD and FFP1 (feedrate for depth and surface)

The feedrate FFP1 is active for all movements in the plane traversed at feedrate. FFD acts for infeeds vertically to this plane.

CPA, CPO and RAD (center point and radius)

You define the position of the circle in the machining plane by the center point (CPA, CPO) and the radius (RAD). Only

positive values are permitted for the radius.

STA1 and INDA (starting and incremental angle)

The arrangement of the long holes on the circle is defined by these parameters.

If INDA=0, the indexing angle is calculated from the number of long holes, so that they are equally distributed around the

circle.

Note

A tool compensation must be programmed before the cycle is called. Otherwise, the c

ycle is aborted and alarm 61000 "No

tool compensation active" is output.

If mutual contour violations of the slots result from incorrect values of the parameters that determine the arrangement and

the size of the slots, the cycle will not start the machini

ng. The cycle is aborted and the error message 61104 "Contour

violation of slots/elongated holes" is output.

During the cycle, the workpiece coordinate system is rotated and offset . The values in the workpiece coordinate system are

shown on the actual val

ue display such that the longitudinal axis of the long hole being machined is positioned on the first

axis of the current machining plane.

After the cycle has been completed, the workpiece coordinate system is in the same position again as it was before th

e

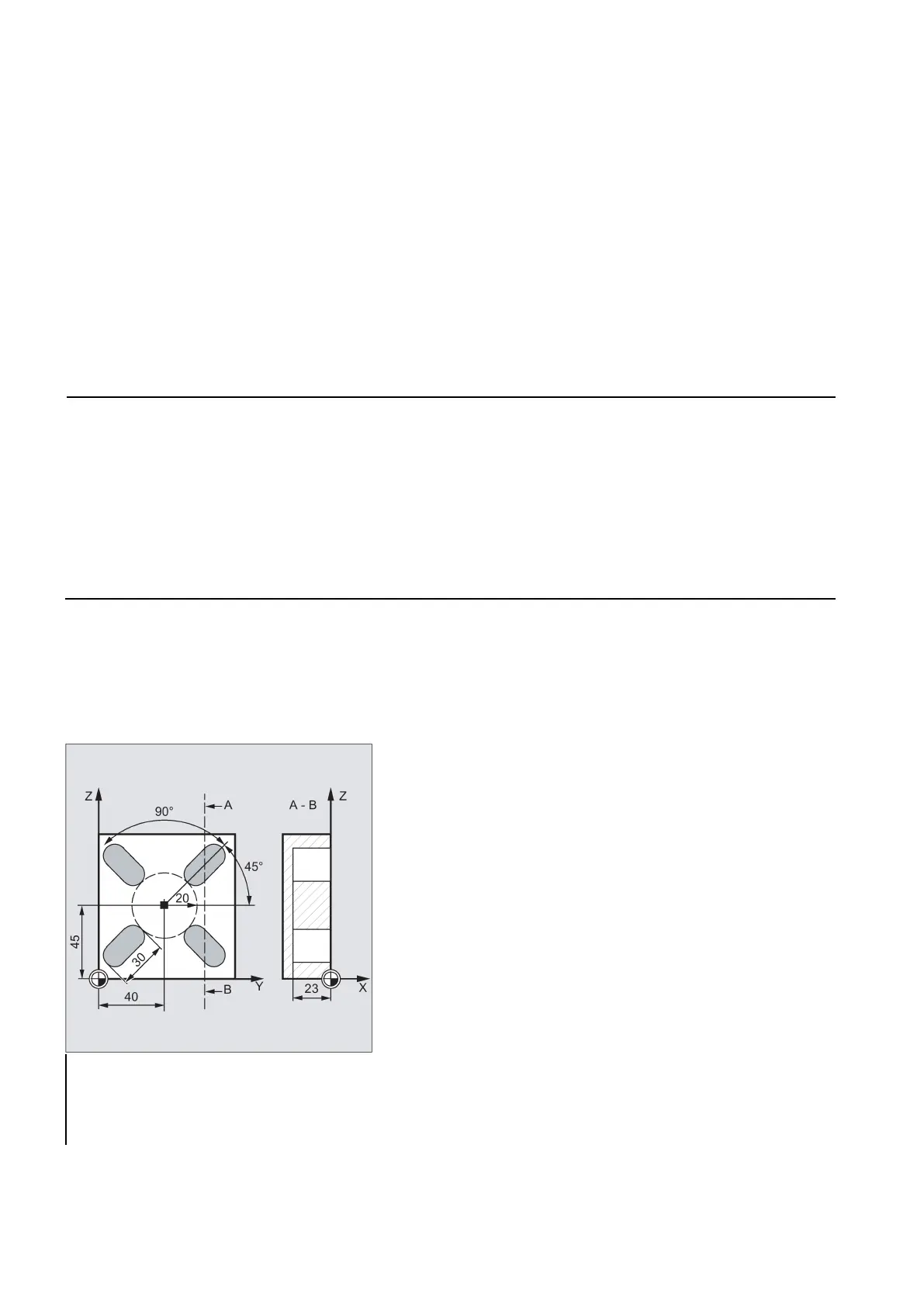

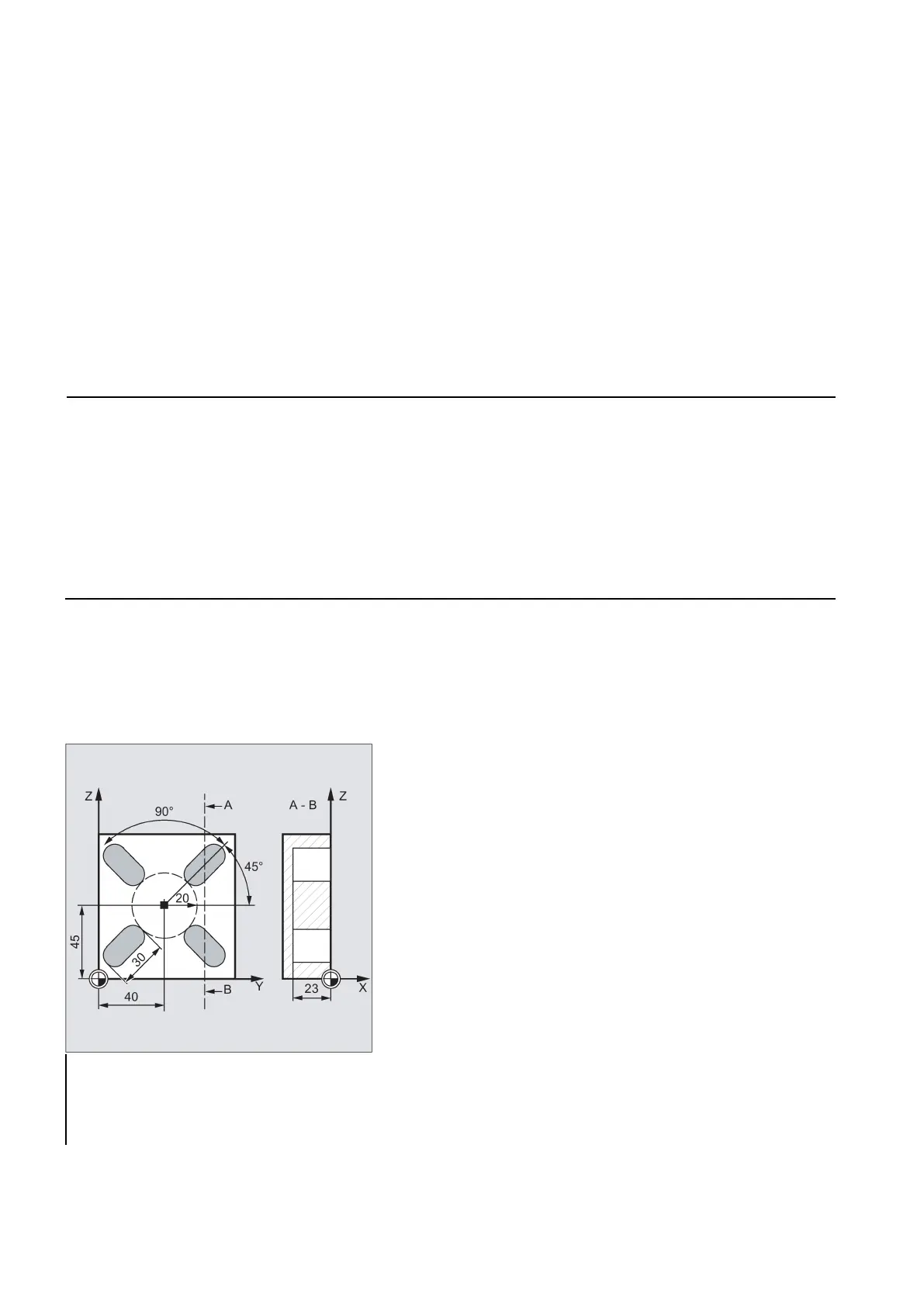

Programming example: Machining slots

By using this program, you can machine four slots of the length 30 mm and the relative depth 23 mm (difference between

the reference plane and the slot root), which are arranged on a circle with the center point Y40 Z45 and the radius 20 mm in

the YZ plane. The starting angle is 45 degrees, and the incremental angle is 90 degrees. The maximum infeed depth is 6

mm, and the safety clearance 1 mm.

See the following programming example for machining slots:

N10 G19 G90 D9 T10 S600 M3

; Specification of the te chnological

values

; Approach starting position

N30 LONGHOLE (5, 0, 1, , 23, 4, 30, 40 , 45, 20, 45, 90, 100

, 320, 6)

Loading...

Loading...