Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

215

Note

A tool compensation must be programmed before the cycle is called. Otherwise, the cycle is aborted and alarm 61000

"No tool compensation active" is output.

If incorrect values are assigned to the

parameters that determine the arrangement and size of the slots and thus cause

mutual contour violation of the slots, the cycle is not started. The cycle is aborted and the error message 61104 "Contour

violation of slots/elongated holes" is output.

the cycle, the workpiece coordinate system is rotated and offset. The values in the workpiece coordinate system

displayed on the actual value display are such that the longitudinal axis of the slot that has just been machined

corresponds to the first axis

of the current machining plane.

After the cycle has been completed, the workpiece coordinate system is in the same position again as it was before the

cycle was called.

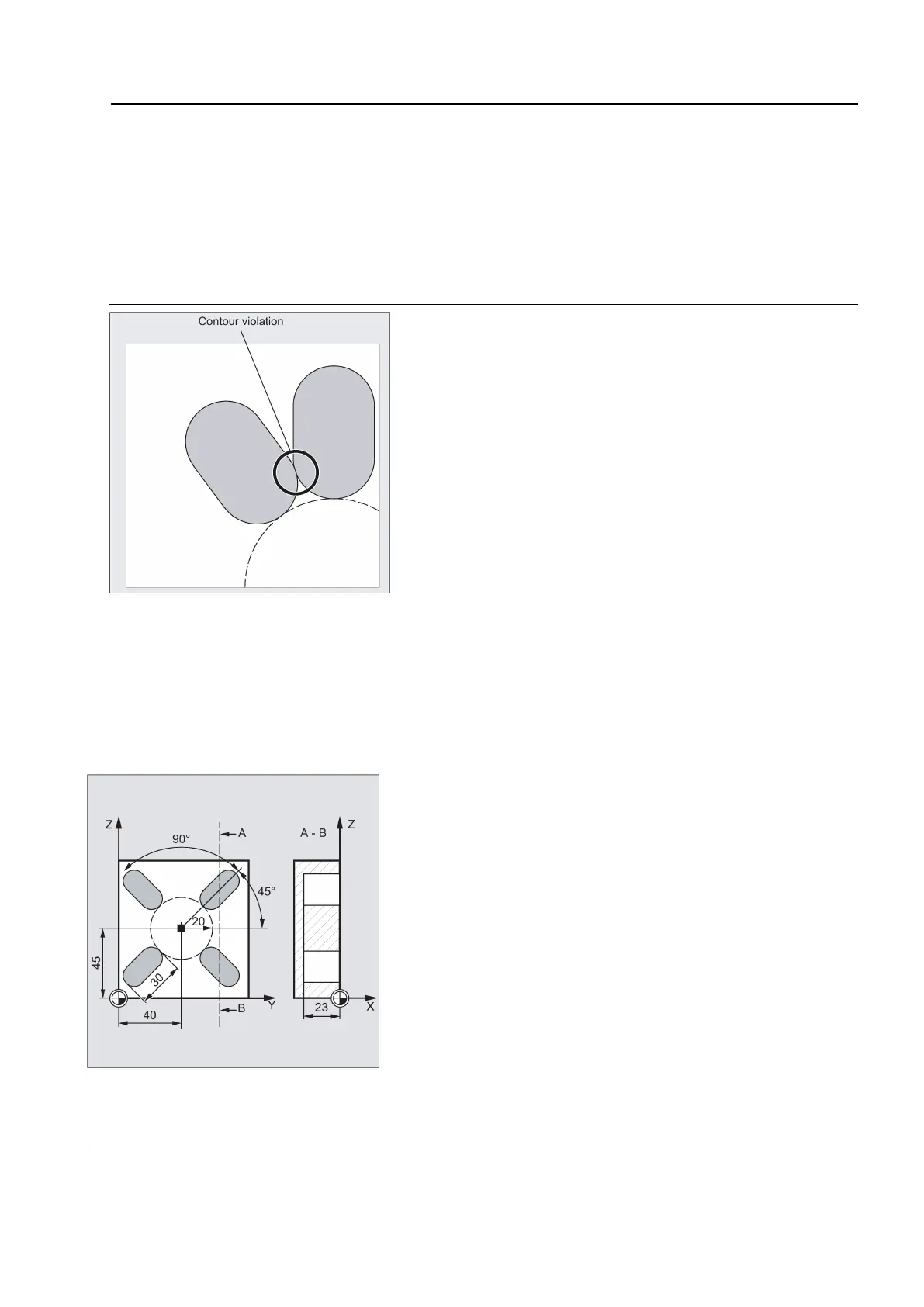

Programming example: Grooves

Four slots are milled.

The slots have the following dimensions: Length 30 mm, width 15 mm and depth 23 mm. The safety clearance is 1 mm, the

final machining allowance is 0.5 mm, the milling direction is G2, and the maximum infeed in the depth is 6 mm.

The slot is to be machined completely. Infeed during finishing is to be performed directly to the pocket depth and the same

feedrate and speed are to be used.

See the following programming example for grooves:

N10 G17 G90 T1 D1 S600 M3

; Specification of technology values

; Approach starting position

N30 SLOT 1(5, 0, 1, -23, , 4, 30, 15, 4 0, 45, 20, 45, 90,

100, 320, 6, 2, 0.5, 0, , 0, )

; Cycle call, VARI, MIDF, FFP2 and SSF

parameters omitted

Loading...

Loading...