Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

297

Activating the contour handwheel in "AUTO" mode

1.

Open the desired NC program in the part program editor window. For more information

about how to create or edit a part program, see Chapter "

Creating part programs

2.

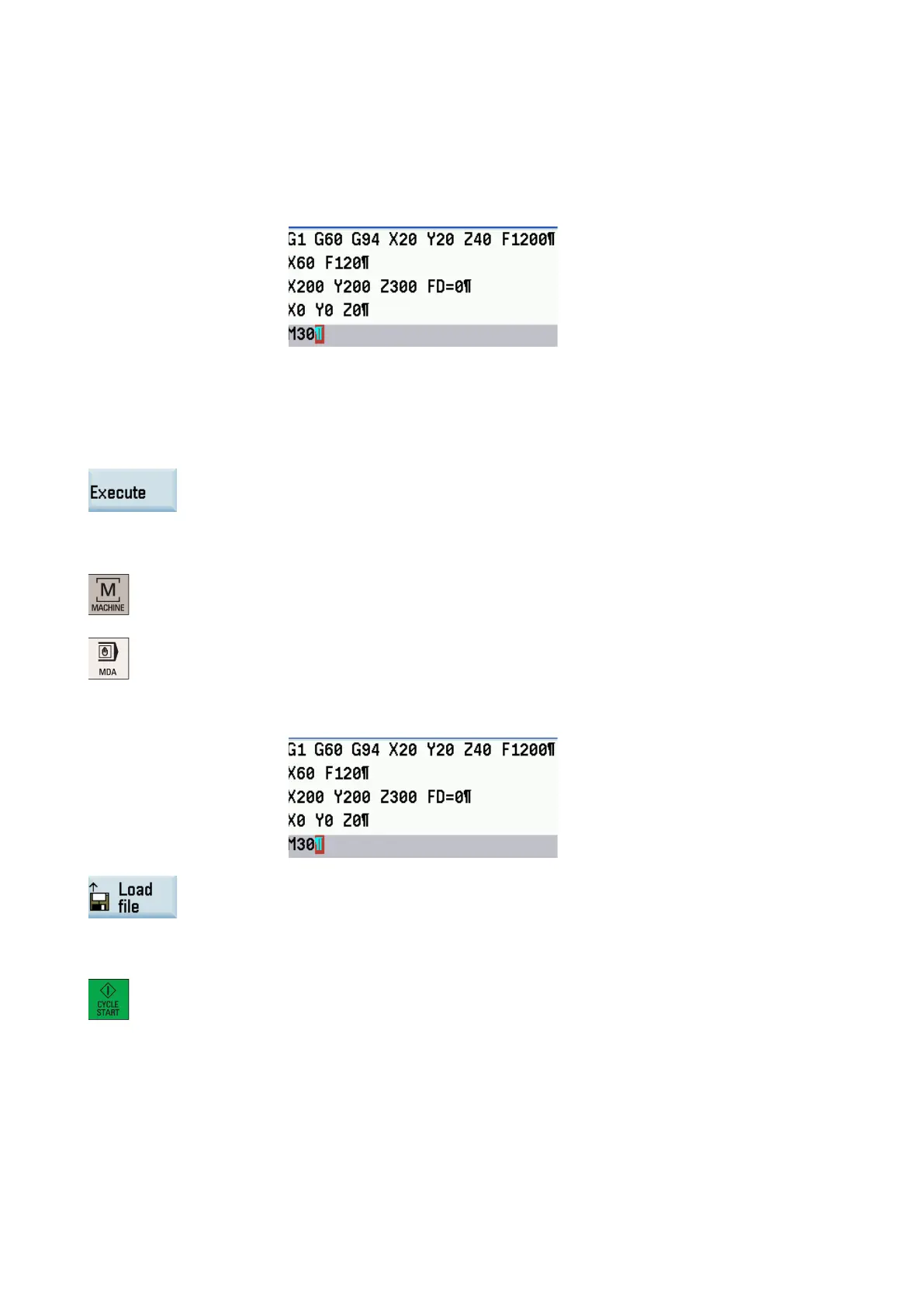

Enter the mandatory instructions "G1" (or "G2"/"G3"), "G94", "G60" and "FD=0" in the

blocks. The blocks are saved automatically. See the following example:

"FD" and "F" cannot appear in the same NC block; otherwise, the control system

prompts an alarm which interrupts the contour handwheel function.

When the block runs to "FD=0", you can control the feedrate of path and synchronized

axes via a handwheel in "AUTO" mode.

3.

Press this softkey to execute the program. The system automatically switches to "AUT

O"

mode in the machining area.

Activating the contour handwheel in "MDA" mode

Select the desired operating area.

2.

3.

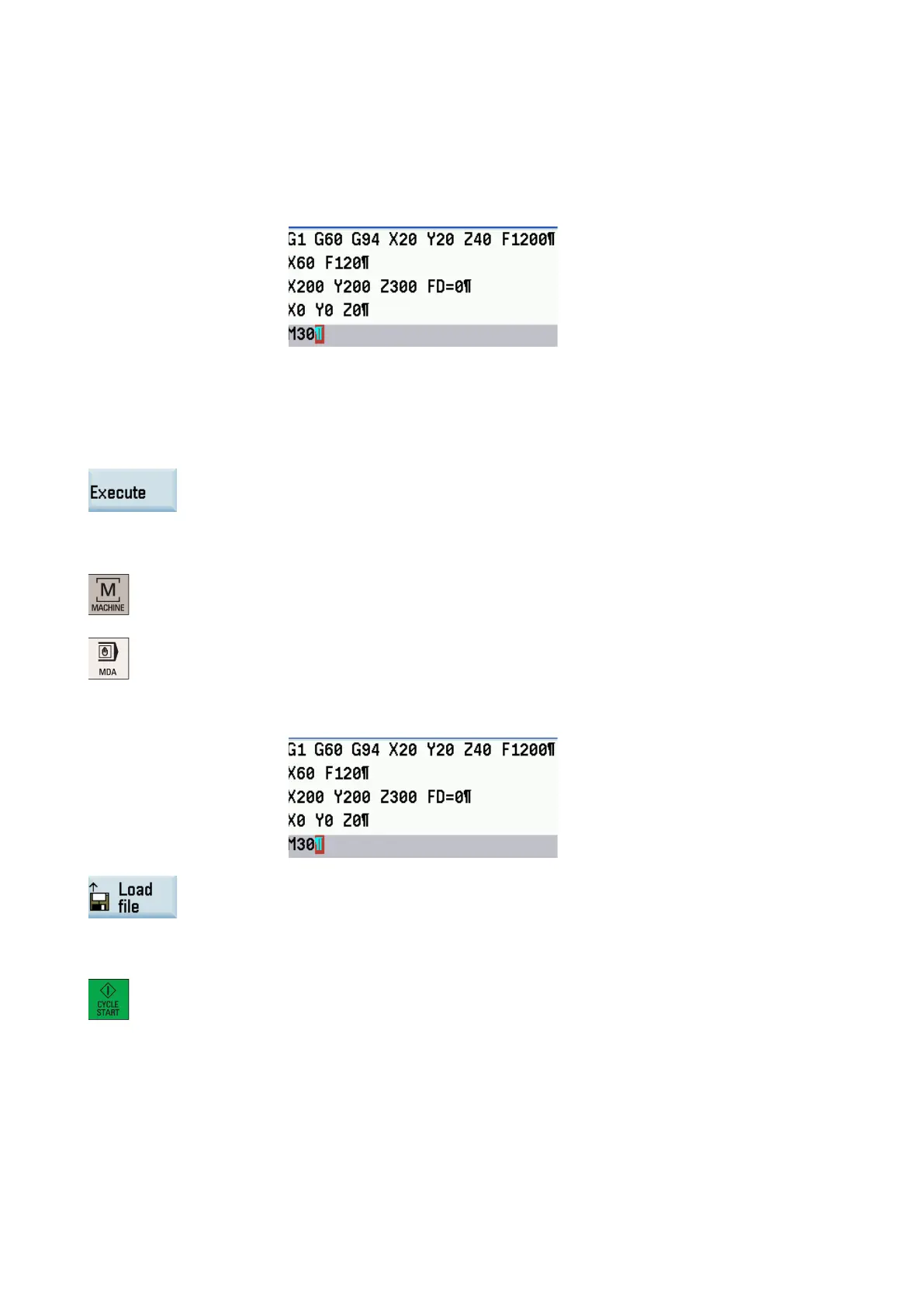

Enter the mandatory instructions "G1" (or "G2"/"G3"), "G94", "G60" and "FD=0" in the

blocks. The blocks are saved automatically. See the following example:

You can alternatively load an existing part program from a system directory by pressing this

softkey if desired and enter "FD=0", "G94" and "G60" in the blocks.

"FD" and "F" cannot appear in the same NC block; otherwise, the control system prompts

an alarm which interrupts the contour handwheel function.

Press this key on the MCP. When the block runs to "FD=0", you can control the feedrate of

path and synchronized axes via a handwheel in "MDA" mode.

Traversing direction of axes

The axis traversing direction depends on the rotation direction of the contour handwheel:

● Clockwise → results in traversing in the programmed direction

If the block-change criterion is reached, the program advances to the next block (response identical to G60).

Loading...

Loading...