3 Safety-Related Functions 11.03

3.5 Safely-reduced speed (SG)

© Siemens AG 2003 All Rights Reserved

3-106 SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

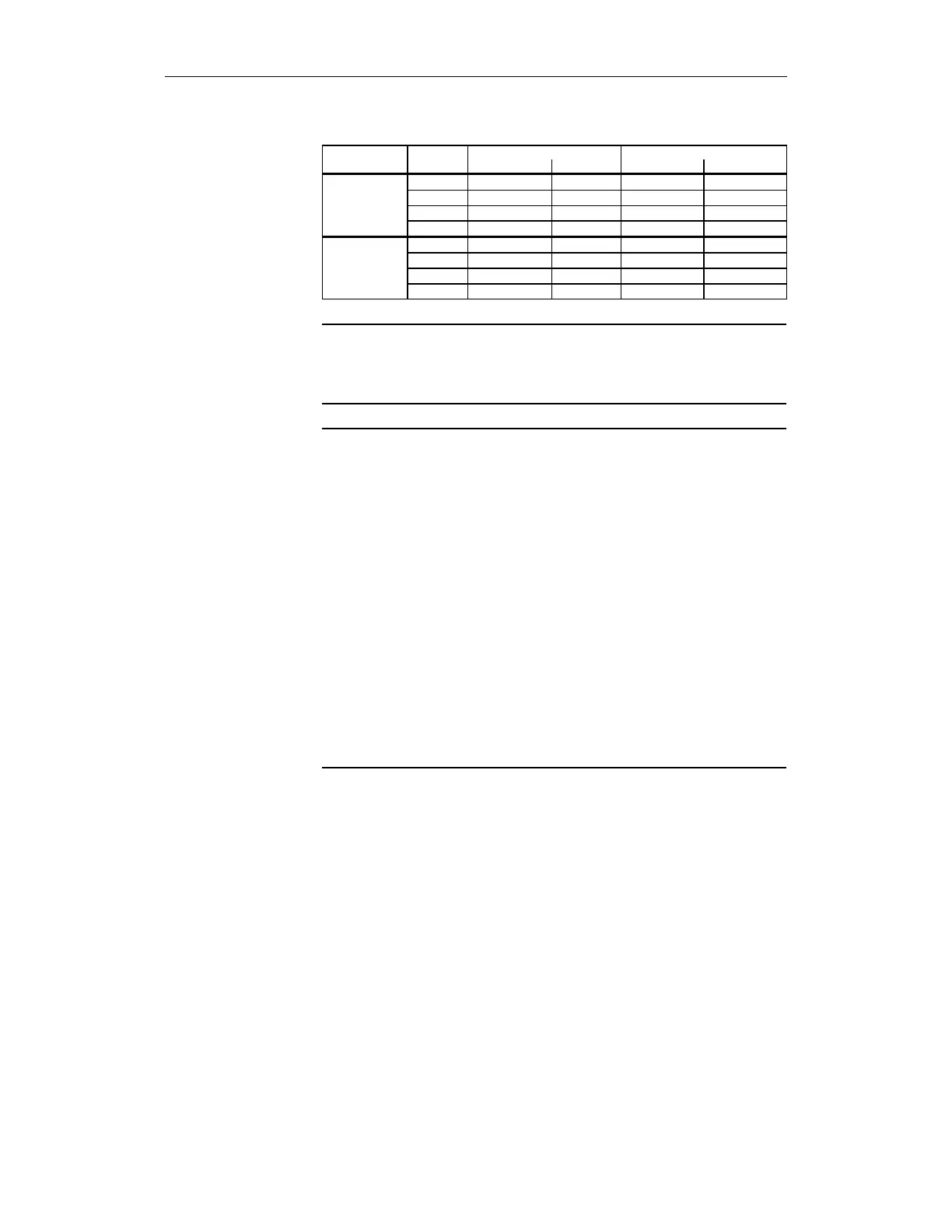

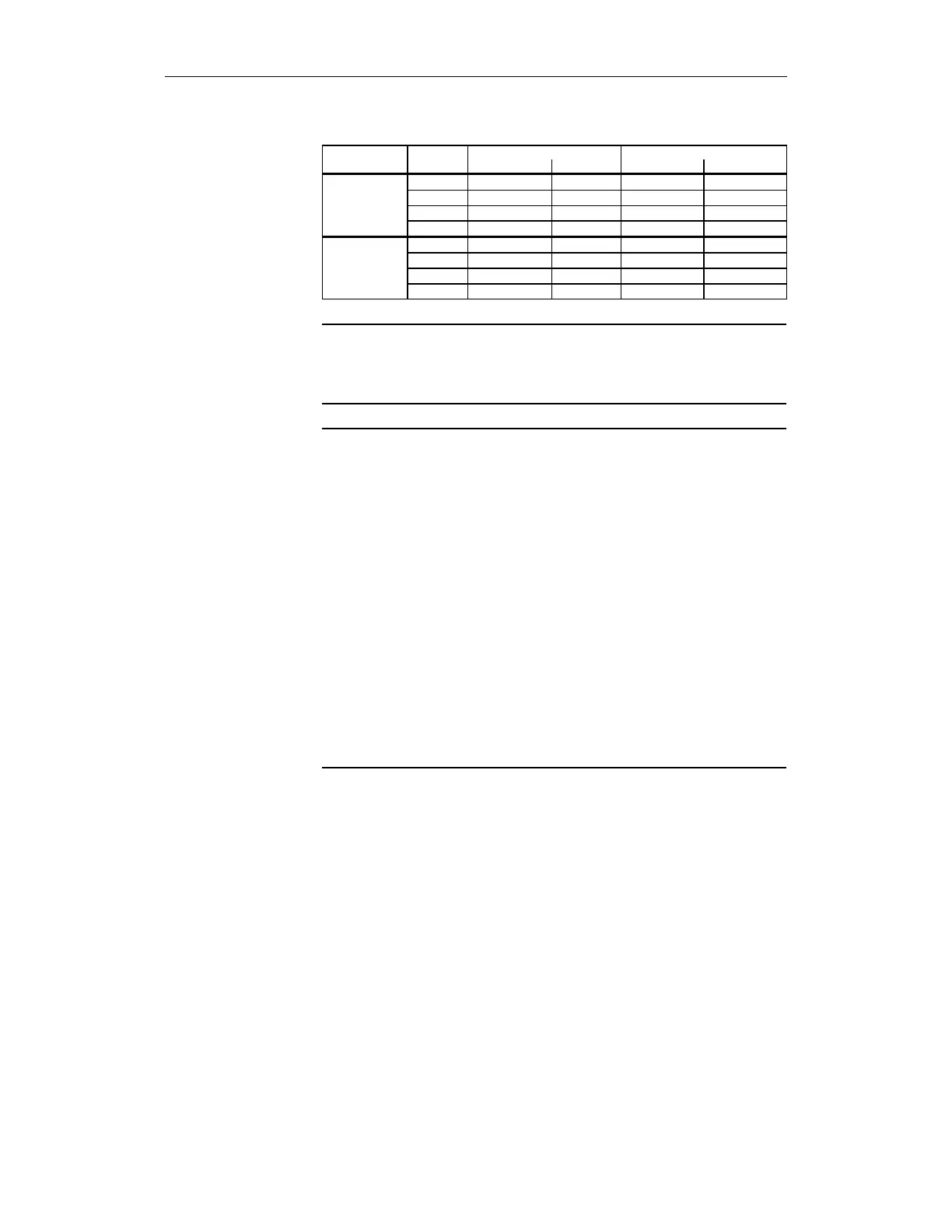

Table3-34 Entering gear ratios into machine data

Stage 840D 611 digital

MD No. Value MD No. Value

Denominator 1

36921[0]

1 1321.0 250

of 2

36921[1]

1 1321.1 400

gearbox 3

36921[2]

1 1321.2 625

encoder/load 4

36921[3]

1 1321.3 1000

Numerator 1

36922[0]

1 1322.0 1000

of 2

36922[1]

1 1322.1 1000

gearbox 3

36922[2]

1 1322.2 1000

encoder/load 4

36922

[

3

]

1 1322.3 1000

Note

For SE/SN, the gear stage must also be changed-over on the NCK side. In

this case, the gear must be changed-over at zero speed or the actual value

synchronization function used.

Note

In the circuit above (Fig. 3-13), the request signals E1/E2 for gear change for

the PLC and drive are supplied from the gear signal.

For SE/SN, the gear stage must also be changed-over on the NCK side.

Because only the pulses of the motor measuring system - and not those of

the direct measuring system - are counted during motion of a motor while

decoupled, this may result in an offset of the SI actual values. As this cannot

be avoided, gear stage changeover without errors is only possible under the

following conditions:

1. The gear stage is selected at zero speed, the time delay does not cause

an offset of the two SI values.

The gear stage is selected when the motor is moving (e.g. oscillating), i.e. the

motor is moving although this cannot be detected at the direct measuring

system. In this case, the following measures can be performed to avoid

errors.

a) MD 36942/or MD 1342 SAFE_POS_TOL must be parameterized as

necessary and re-synchronization of the spindle (<axis DB>.DBX 16.6 or DBX

16.7: active measuring system) must be triggered after gear changeover (if

this has not already been done) to re-align the SI actual values

b) The actual value synchronization function must be used

Example 2: Spindle with a 1-encoder system

• The gear stage is selected from an NC program with an H function via the

PLC user program.

•

Gear ratios are selected through 2 channels.

• The encoder system is connected to the "direct measuring system" input

on the 611 digital closed-loop control module.

• The machine data for the "input assignment gear ratio selection (bits 0,

1, 2)" for the NCK are described in

Chapter 4, "Machine data for SINUMERIK 840D".

Assumptions for

example 2

Loading...

Loading...