11.03 4 Data Descriptions

4.1 Machine data

© Siemens AG 2003 All Rights Reserved

SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

4-239

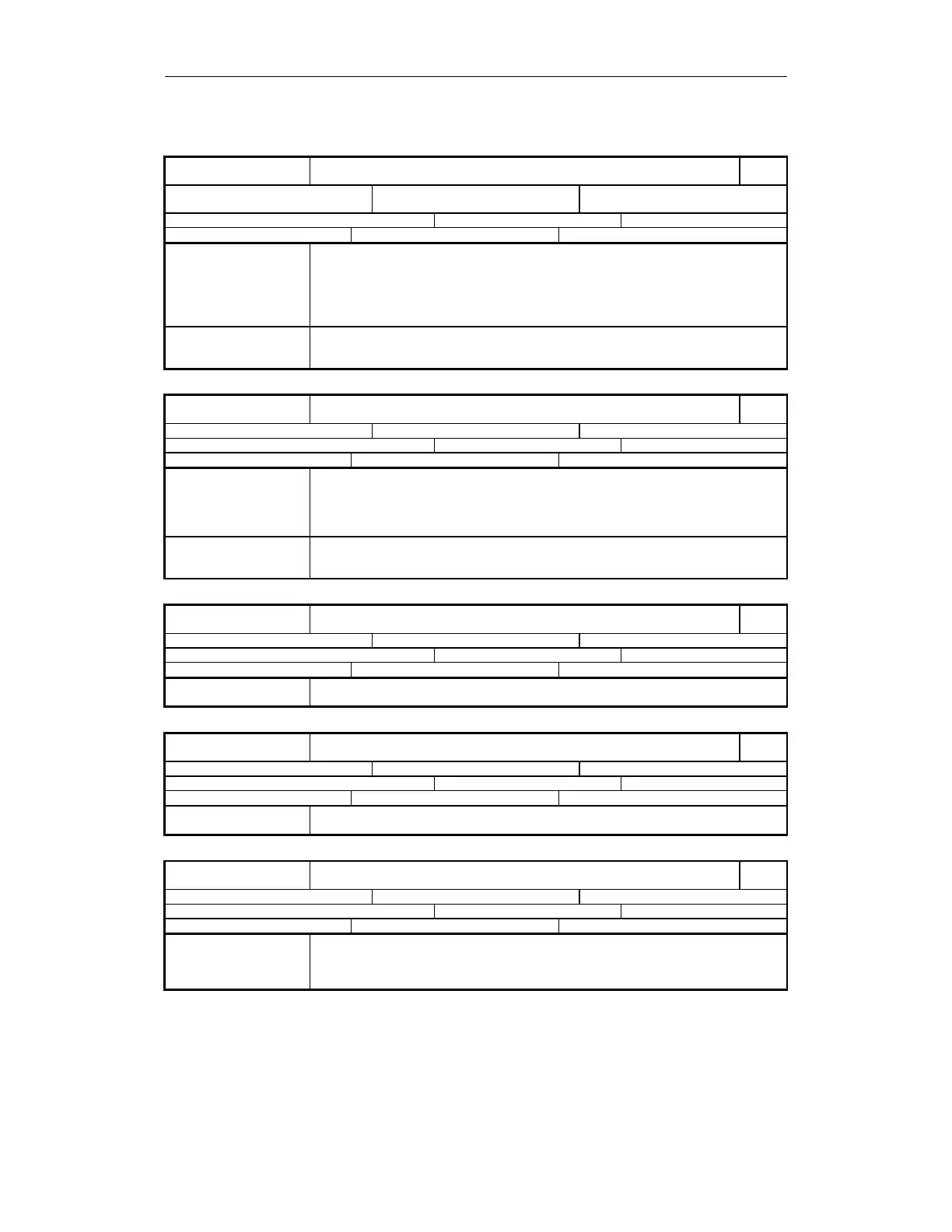

36995

MD number

$MA_SAFE_STANDSTILL_POS

Standstill position

840D

Default value 0 Min. input value:

-2 147 483 647

Max. input value:

2 147 483 647

Change becomes effective after POWER ON: Protection level (R/W) 0/0 Unit: -

Data type: DWORD Applies from SW 3.4

Meaning The position at which the axis has currently stopped is displayed in this MD.

To be able to perform a plausibility check on the axis referencing when the control system

is powered-up the next time, the current axis position is saved permanently when the

following events take place:

•

When safe operating stop (SBH) is selected

• Cyclically when SE/SN is active

Special cases, errors Any manual changes to the MD are detected the next time the control is powered-up and

the axis reference checked for plausibility. "User agreement" is required again after

referencing.

36997

MD number

$MA_SAFE_ACKN

User agreement

840D

Default: 0 Min. input value: 0 Max. input value: FF FF FF FF

Change becomes effective after POWER ON: Protection level (R/W) 7/2 Unit: Hexadecimal

Data type: DWORD Applies from SW 3.4

Meaning The user agreement status is displayed in this machine data.

The user can confirm or cancel his "user agreement" via an appropriate screen display.

If it is internally detected in the software that the reference to the machine has been lost,

then the "user agreement" is automatically cancelled (e.g. during gear changes, or if the

plausibility comparison with the stored standstill position fails during referencing).

Special cases, errors Any manual changes to the MD are detected the next time the control is powered-up and

the axis reference checked for plausibility. "User agreement" is required again after

referencing.

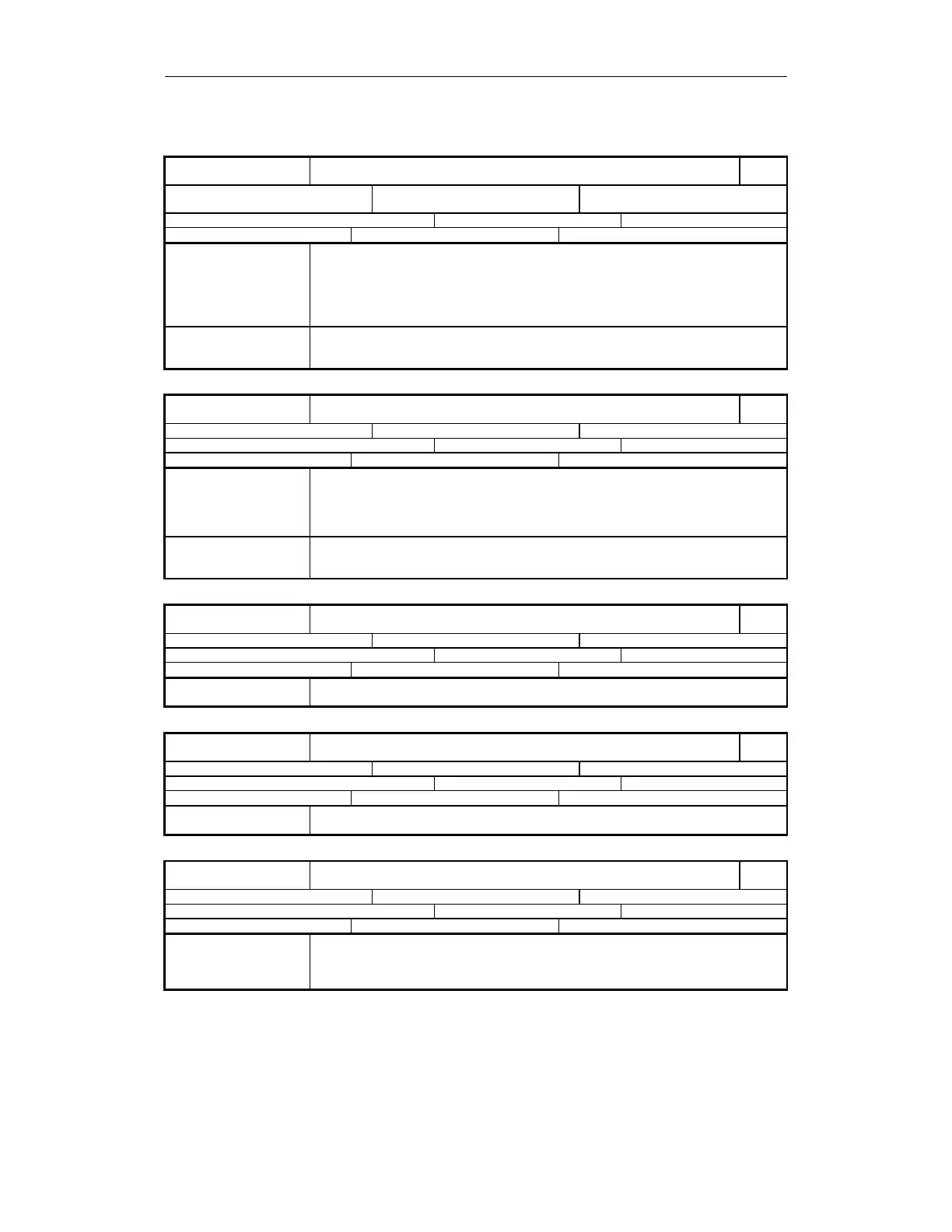

36998

MD number

$MA_SAFE_ACT_CHECKSUM

Actual checksum

840D

Default: 0 Min. input value: 0 Max. input value: FF FF FF FF

Change becomes effective after POWER ON: Protection level (R/W) 7/- Unit: Hexadecimal

Data type: DWORD Applies from SW 3.4

Meaning The actual checksum calculated after POWER ON or for a RESET, over the current

values of safety-relevant machine data is entered here.

36999

MD number

$MA_SAFE_DES_CHECKSUM

Setpoint checksum

840D

Default: 0 Min. input value: 0 Max. input value: FF FF FF FF

Change becomes effective after POWER ON: Protection level (R/W) 7/1 Unit: Hexadecimal

Data type: DWORD Applies from SW 3.4

Meaning This data contains the setpoint (reference) checksum of the actual values of safety-

relevant machine data that was saved during the last machine acceptance test.

37000

MD number

$MA_FIXED_STOP_MODE

Travel to fixed endstop mode

840D

Default: 0 Min. input value: 0 Max. input value: 3

Change becomes effective after POWER ON: Protection level (R/W) 7/1 Unit: Hexadecimal

Data type: BYTE Applies from SW

Meaning Bit 0: Selects "Traverse to fixed endstop" from the part program or

synchronous actions.

Bit 1: Selects "Traverse to fixed endstop" for the function test of the

braking mechanical system from the PLC

Loading...

Loading...