4 Data Descriptions 11.03

4.1 Machine data

© Siemens AG 2003 All Rights Reserved

4-238 SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

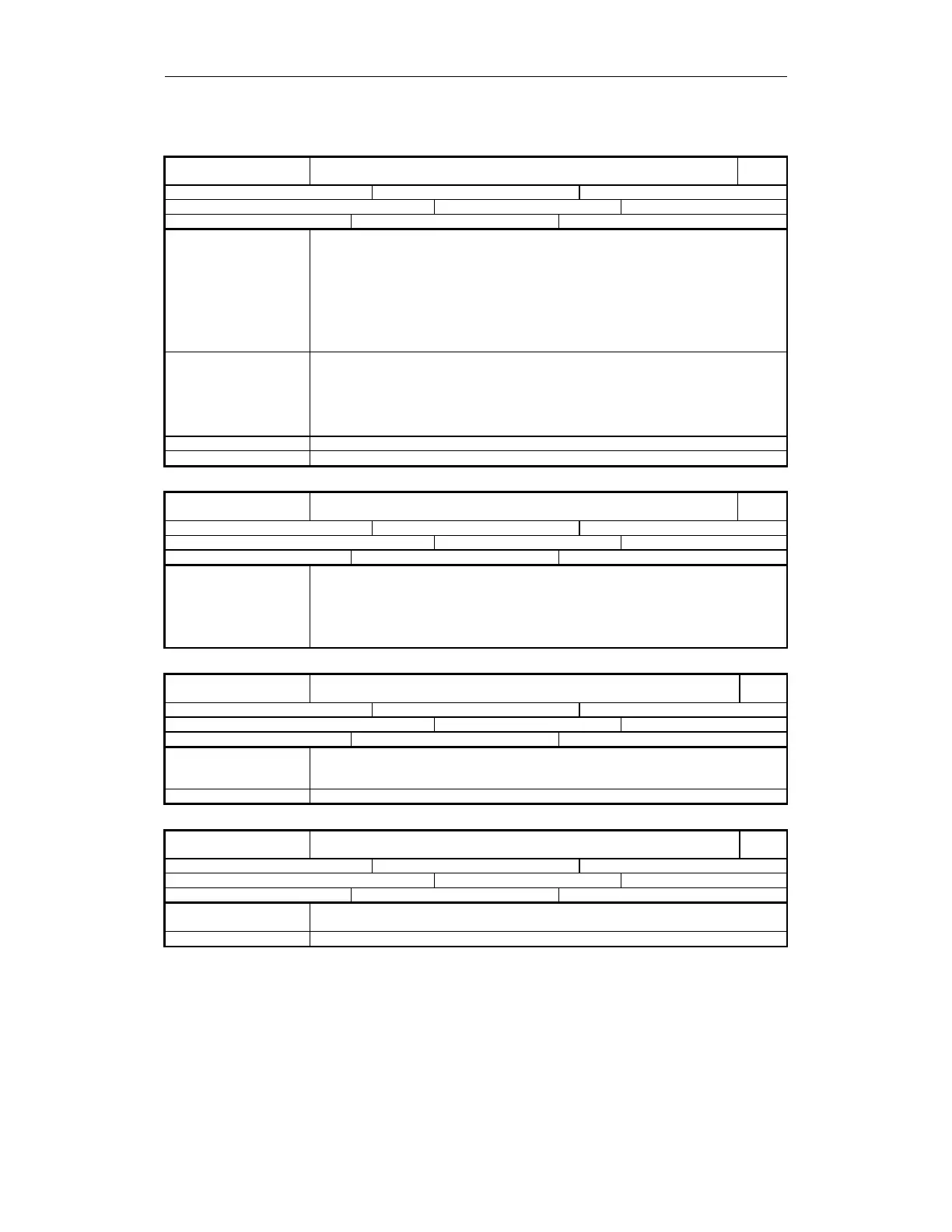

36990

MD number

$MA_SAFE_ ACT_STOP_OUTPUT[n]: 0...3

Output assignment active STOP

840D

Default: 0 Min. input value: 0 Max. input value: -

Change becomes effective after POWER ON: Protection level (R/W) 7/2 Unit: -

Data type: DWORD Applies from SW 4.4.18

Meaning This data defines the assignment of the states

"STOP A/B is active", "STOP C is active" and "STOP D is active" to an output terminal or

system variable.

Structure: Refer to coding of output assignment

n associated status (on "1" level)

n = 0 "STOP A/B is active "

n = 1 "STOP C is active "

n = 2 "STOP D is active "

n = 3 "STOP E is active"

Special cases, errors

•

Test stop can be detected using SGA "Pulse enable".

• "STOP A/B is active" can only be used for "leading brake control" because after the

time specified in MD36956: $MA_SAFE_PULSE_DISABLE_DELAY changeover is

made from STOP B to STOP A.

• "STOP A/B is active", "STOP C is active" and "STOP D is active" can be used for the

forced checking procedure of external STOPs.

Corresponds with … MD 36980: $MA_SAFE_ SVSS_STATUS_OUTPUT

Further references Refer to Chapter 3, "External STOPs"

36992

MD number

$MA_SAFE_CROSSCHECK_CYCLE

Displays axial crosswise comparison clock cycle

840D

Default: 0 Min. input value: 0 Max. input value: -

Change becomes effective after POWER ON: Protection level (R/W) 7/2 Unit: -

Data type: DWORD Applies from SW 6.3

Meaning Indicates effective axial comparison clock cycle in seconds.

Obtained from INFO_SAFETY_CYCLE_TIME and the number of data to be compared

crosswise.

The axial value displayed depends on the associated drive module, since the length of the

crosswise data comparison lists between Performance-1/Standard-2 and Performance-2

modules is different.

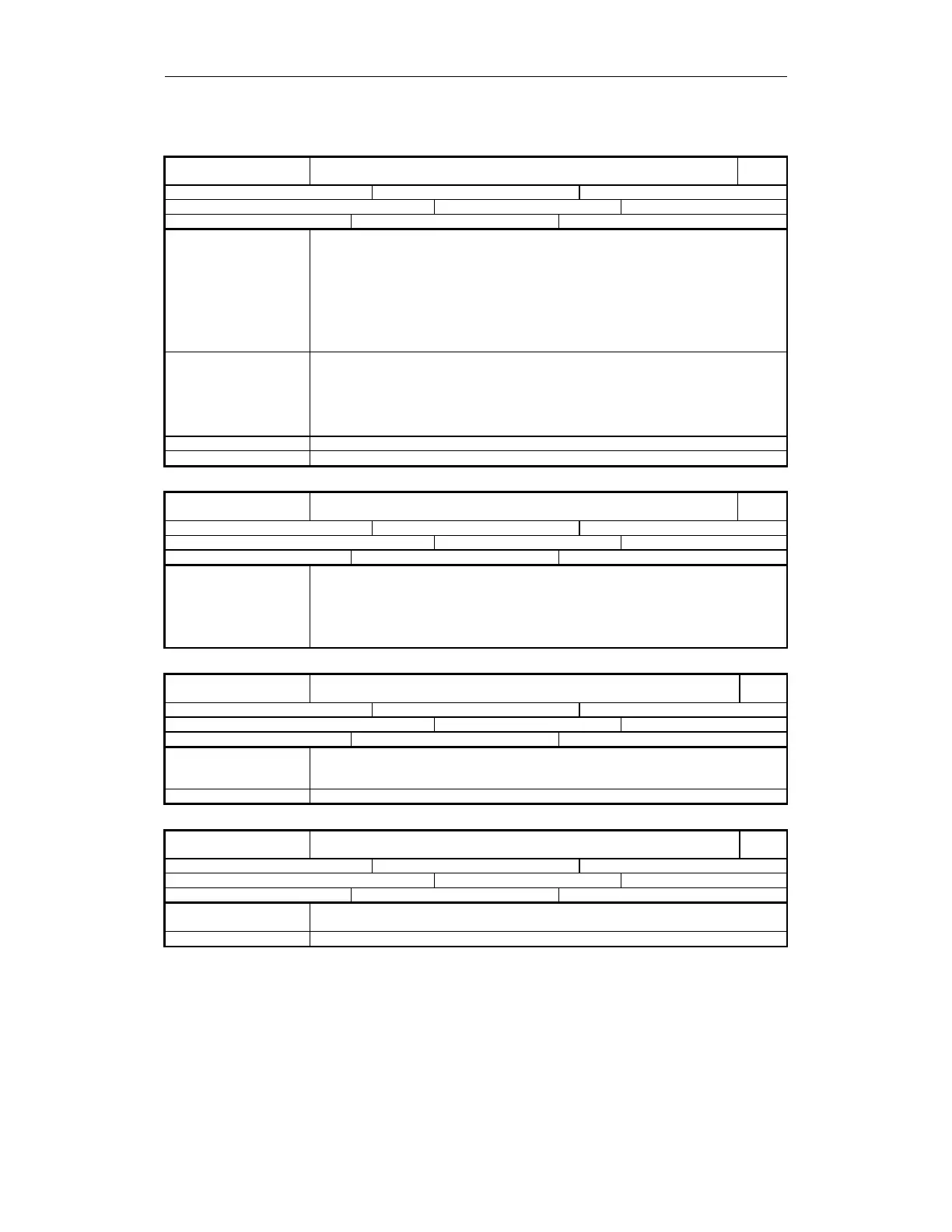

36993

MD number

$MA_SAFE_CONFIG_CHANGE_DATE[n]; n=0...4

Date/time of last configuration change of safety-relevant NCK machine data

840D

Default: "Blank" Min. input value: - Max. input value: -

Change becomes effective after POWER ON: Protection level (R/W) 7/2 Unit: -

Data type: STRING Applies from SW 5.2

Meaning Display data which logs when safety-relevant NCK machine data are activated. The last

change is logged in the MD with

field index 0. Previous times in fields 1...4.

Special cases, errors

36994

MD number

$MA_SAFE_PREV_CONFIG[n]; n=0...4

Save data to verify safety configuration changes

840D

Default: "Blank" Min. input value: - Max. input value: -

Change becomes effective after POWER ON: Protection level (R/W) 7/7 Unit: -

Data type: STRING Applies from SW 3.4

Meaning If the safety configuration is changed, safety-relevant configuration data is stored in this

field.

Special cases, errors

Loading...

Loading...