Detailed Description

2.4 Tool: Tool radius compensation 2D (TRC)

Tool Compensation (W1)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-53

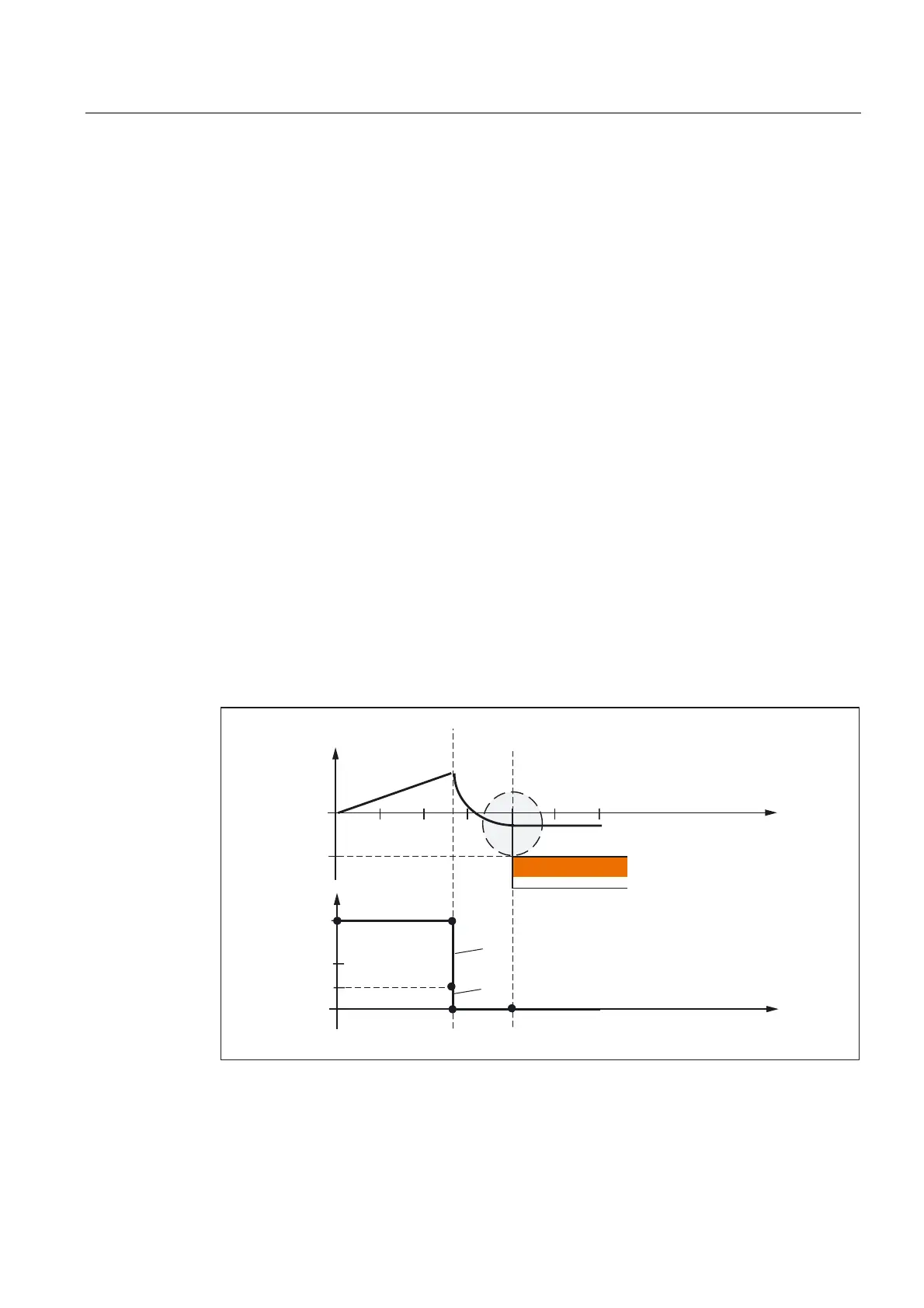

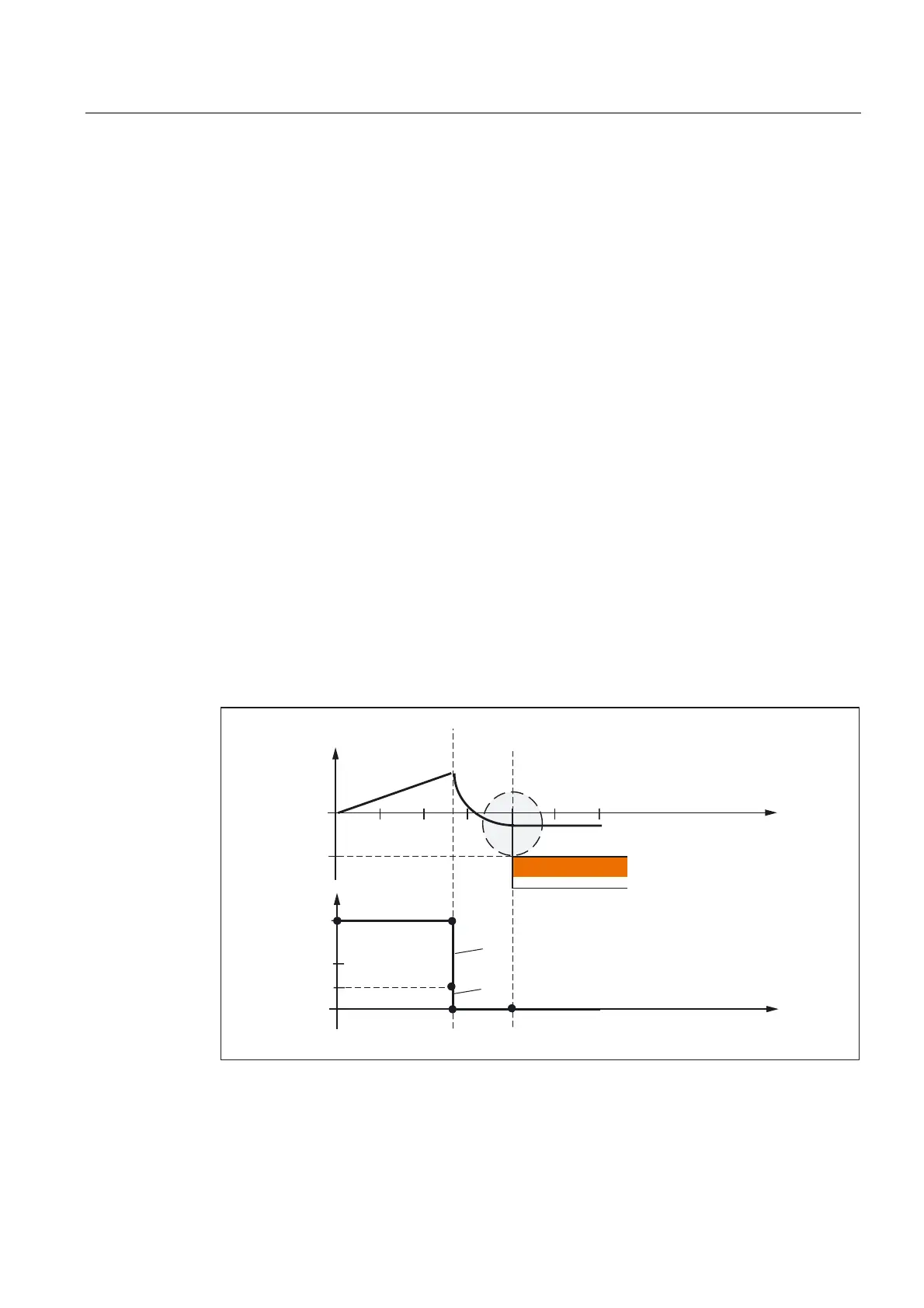

• Velocity of the preceding block (typically G0).

All movements from point P

0

to point P

2

are performed at this velocity, i.e., the movement

parallel to the machining plane and the part of the infeed movement up to the safety

clearance.

• Programming the feedrate with FAD

– FAD programmed with G340:

Feedrate from P

2

or P

3

to P

4

.

– FAD programmed with G341:

Feedrate of the infeed movement perpendicular to the machining plane from P

2

to P

3

.

If FAD is not programmed, this part of the contour is traversed at the velocity, which is

active modally from the preceding block, in the event that no F command defining the

velocity is programmed in the SAR block.

– Programmed response:

FAD=0 or negative → Alarm Output

FAD=...

→ Programmed value acts in accordance with the active G code of

group 15 (feed type; G93, G94, etc.)

FAD=PM(...)

→ Programmed value is interpreted as linear feed (like G94),

irrespective of the active G code of group 15

FAD=PR(...)

→ Programmed value is interpreted as revolutional feed (like G95),

irrespective of the active G code of group 15

Example:

3

))

)

*

;

;

3

3

3

3

*

=

<

Loading...

Loading...