38

Replacement Procedures

Service Manual

SKOPE BME-N ActiveCore

Compressor

Electrics

The compressor electrics are located on the front of the compressor.

To access the compressor electrics, remove the refrigeration cartridge (see page 31) and

cartridge cover (see page 34). The capacitor unclips from the relay cover, and the relay cover

unclips from the compressor.

Refrigeration Cartridge

Cartridge

Removal

For detailed instructions on removing the cartridge, refer to the unit removal instructions on the

instruction sheet attached to the back of the cabinet, or on page 31 of this service manual.

Diagnostics The following test is useful in the workshop to diagnose a short of gas situation. Perform the

test before opening the refrigeration system.

It is useful to have a correctly operating cartridge running beside the cartridge being serviced

to compare behaviour.

Note: These diagnostic procedures are indicative only.

Procedure 34: Refrigeration system diagnostic test

Before you start

Make sure you are in a suitable workshop (see page 30).

1. Disconnect the cabinet from the mains power supply (see page 22).

2. Remove the refrigeration cartridge.

3. Remove the cartridge cover.

4. Place the cartridge on bench and connect the service probe to the red plug on the cartridge.

5. Connect the refrigeration cartridge to the mains power supply and allow to run for approximately

10 minutes until the evaporator temperature stabilises.

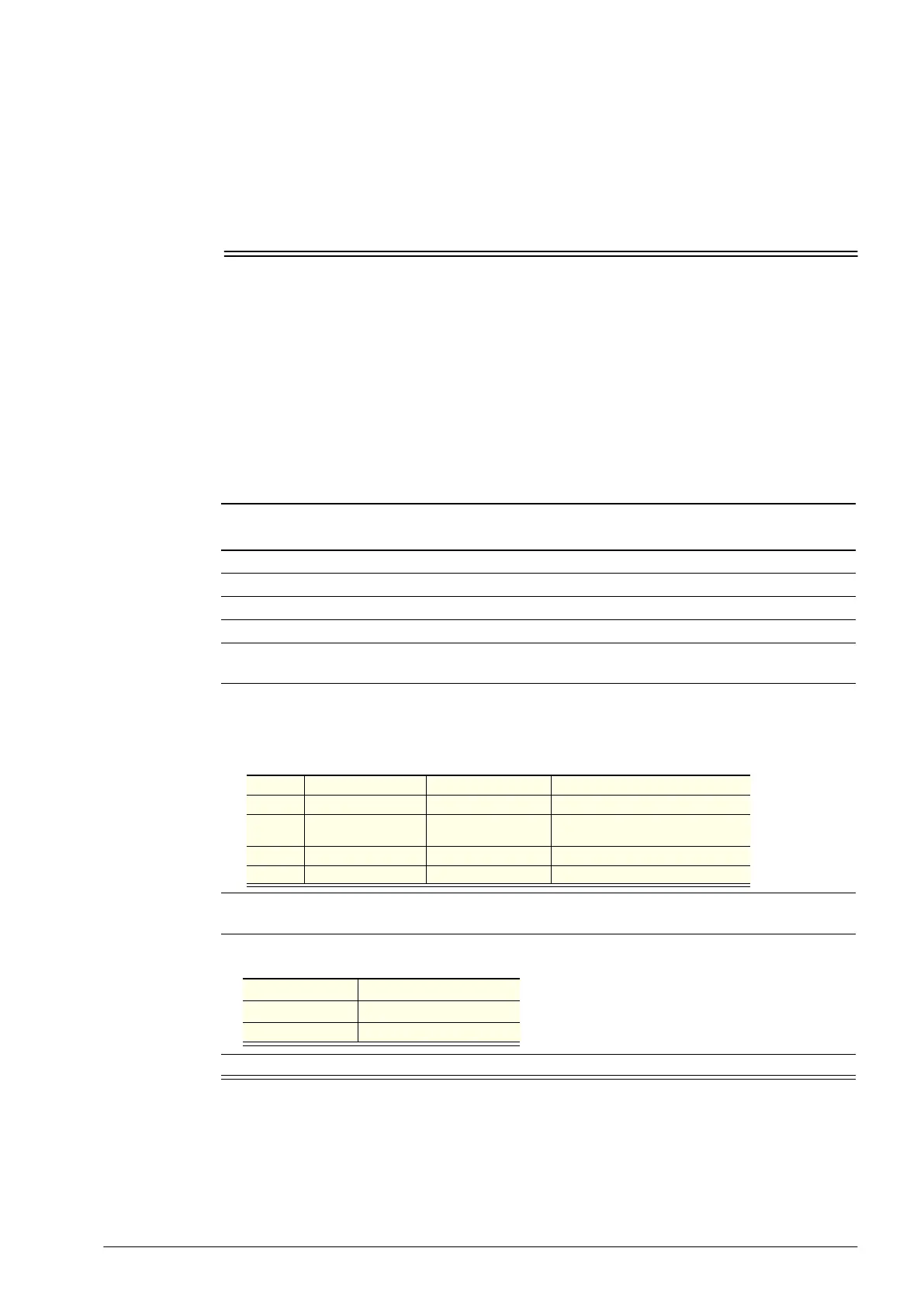

6. Refer to the table below to determine if the system charge is correct.

A system with the correct refrigerant charge will frost back towards the compressor. The point where

the frost stops is affected by the ambient temperature.

The table below details the frost stop point on a correctly charged system running on the bench.

7. If the suction pipe frosts to the appropriate frost stop point, the charge is likely correct. If the frost

does not go back to the point shown there may be a capillary blockage or compressor fault.

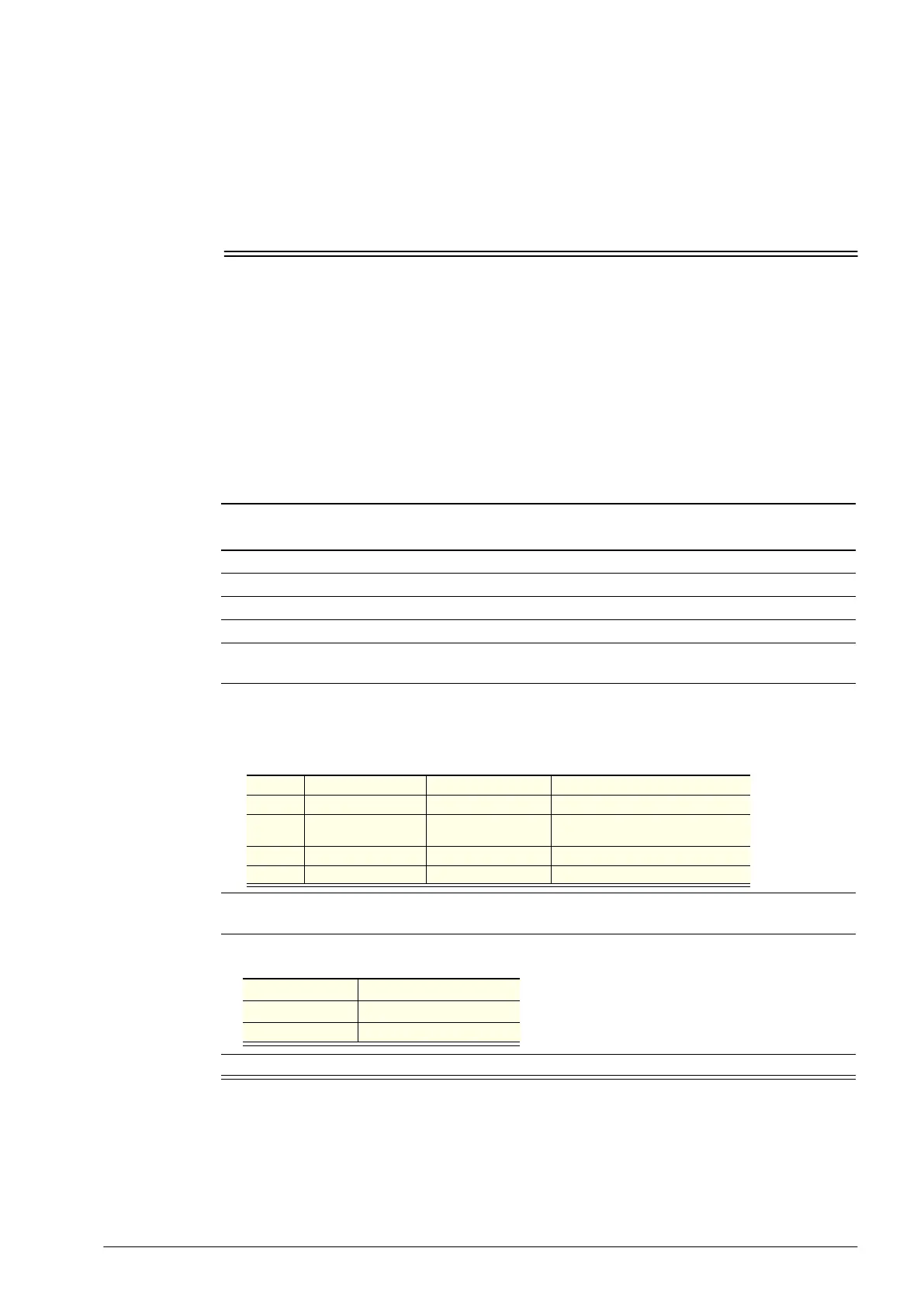

8. Use the table below to determine whether the system is short of refrigerant or a has blocked

capillary.

9. After fault has been diagnosed and repaired, reassemble the refrigeration system and test run.

Ambient 50% charged 75% charged 100% charged

10°C Cold with light sweat Cold with light sweat Frosting to compressor

20°C Cold with light sweat Sweating 50mm from

compressor

Frosting to compressor

30°C Dry Dry Frosting 20mm from compressor

40°C Dry Dry Sweating 50mm from compressor

Diagnosis Frost back (after 10 mins)

Blocked capillary None

Normal operation Refer to table above

Loading...

Loading...