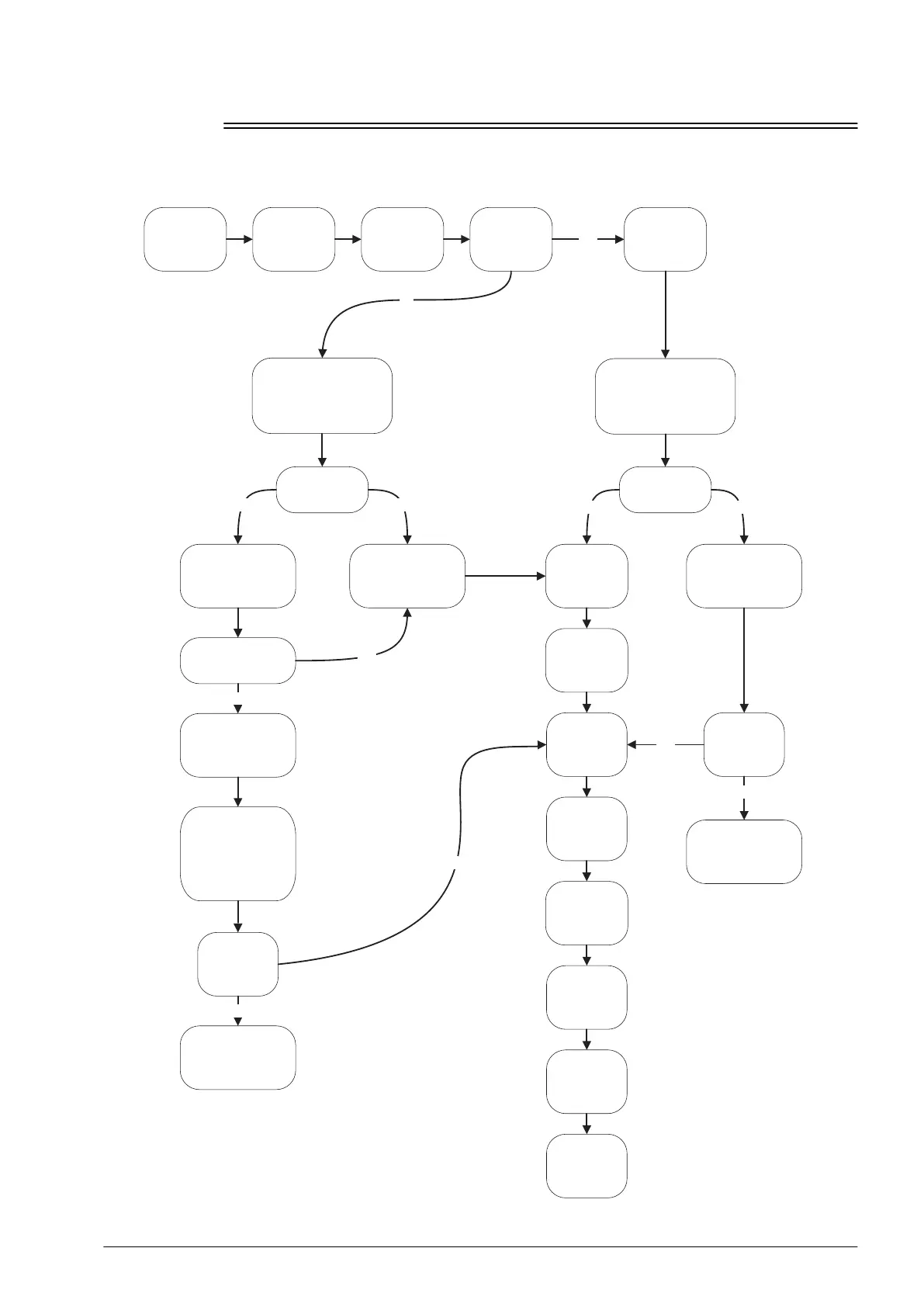

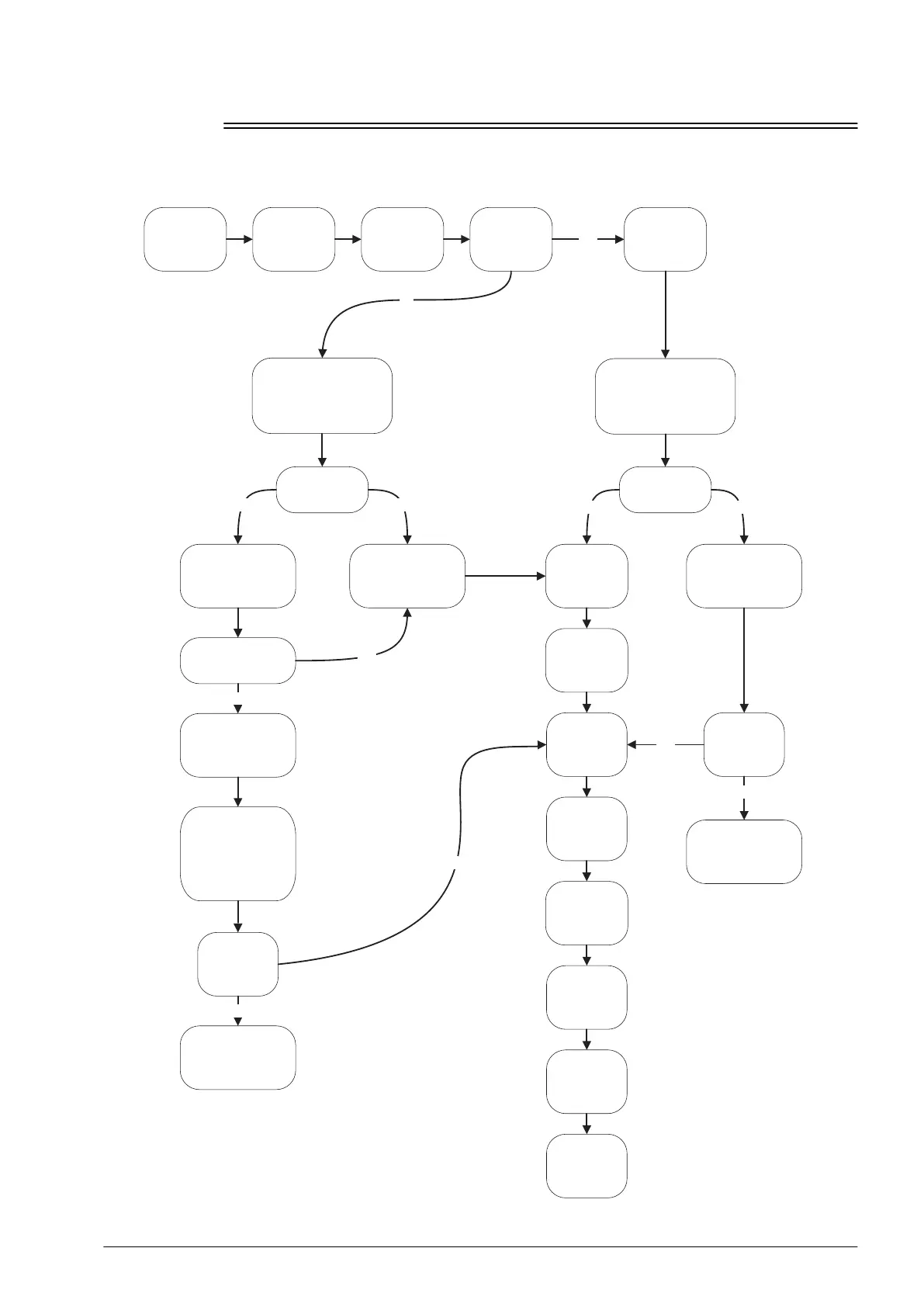

If a customer reports a “not cooling” fault, and it has been established that the cabinet is not

cooling, follow the procedure below when making the service visit.

Download data

using SCS

Connect Track

app (outside 1.5 m

safe work area).

Create a 1.5 m

safe

working area

around the

Calibrate gas

detector (away

from potential

gas source).

Is gas detected?

Check refrigeration

characteristics

and component

operations to

determine fault.

Place gas detector on ground in

front of cabinet and wait 10

seconds. If no gas detected on

floor, open cooler door and

check for gas inside cabinet.

Is gas detected?

Refrigeration

system is

considered to

have a gas leak.

Place gas detector on ground in

front of cabinet and wait 10

seconds. If no gas detected on

floor, open cabinet door and

check for gas inside cabinet.

Tag power supply

with ‘Out of

Service’ warning

label.

Ensure cartridge

is available and

customer agrees

with swap.

Safely remove

cartridge from

cabinet and move

to the service

vehicle area.

Fit replacement

cartridge.

Reload data

downloaded in

cell 2 (not req. if

original controller

still used).

If fault is component

(NOT sealed

refrigeration system),

replace onsite with

authorised OEM part

Test for correct

operation

Arrange

refrigeration

cartridge swap.

Is fault in sealed

refrigeration

system?

Is gas detected?

Check refrigeration

characteristics and

component operations

operations to determine

the fault. See Procedure

Is fault in sealed

refrigeration

system?

If fault is component

(NOT sealed

refrigeration system),

replace onsite with

authorised OEM part

Is mains socket

accessible?

Isolate at mains

socket (unplug).

No

No

Yes

Yes

Yes

No

No

Remove electrics box

cover and unplug IEC

connector to isolate

the power.

Remove kick panel and

use gas detector to check

around electrics box on

front of refrigeration unit

Unload cabinet and move

to access mains socket.

Yes

No

No

Yes

Yes

cabinet.

20: To determine if

there is a sealed

system fault.

Loading...

Loading...