5-46

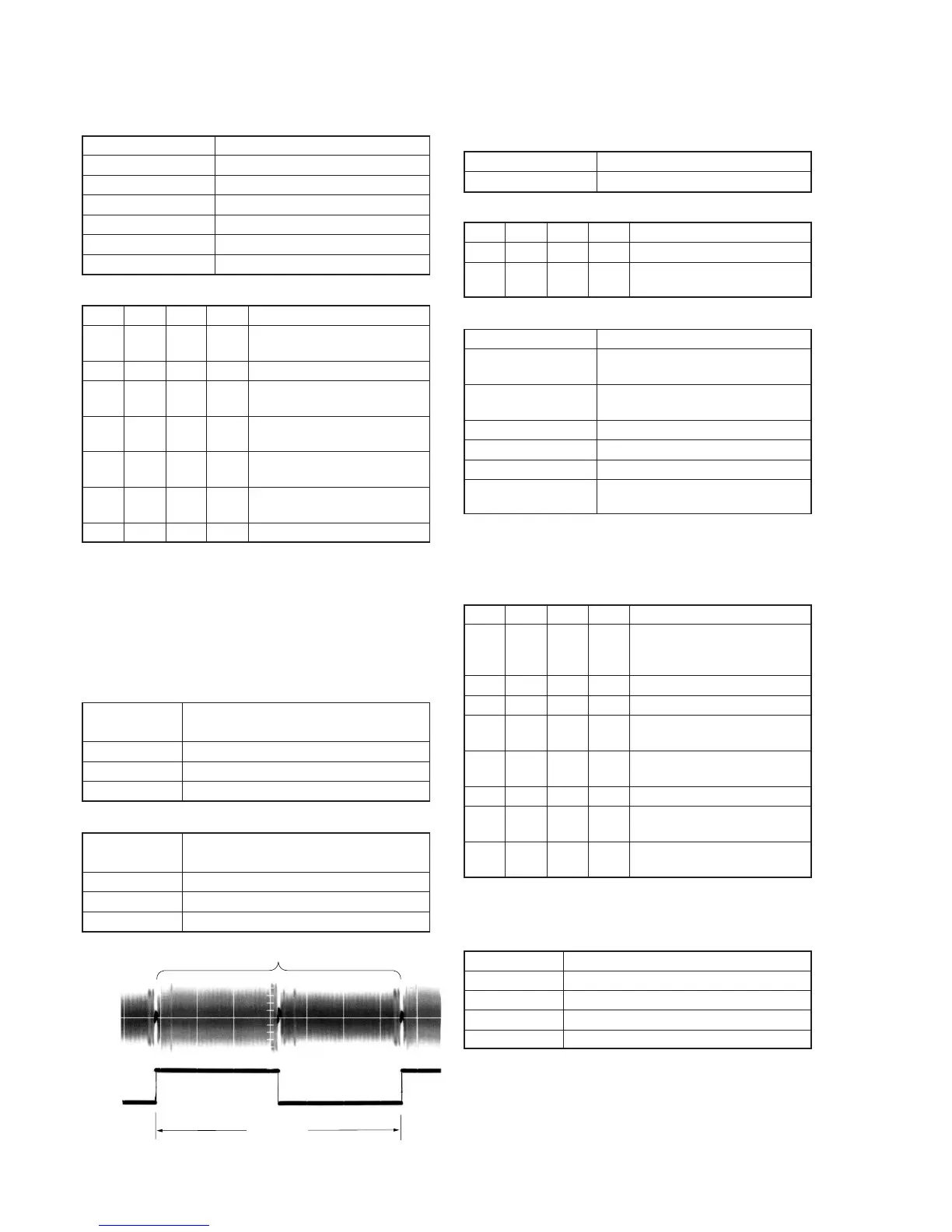

4. Switching Position Adjustment (VC-242 Board)

Mode VTR playback

Signal SW/OL reference tape (XH2-3)

Measurement Point Display data of page: 3, address: 03

Measuring Instrument Adjustment remote commander

Adjustment Page C

Adjustment Address 10, 11, 12, 13

Specified Value 00

Adjusting method:

Order Page

Address

Data Procedure

1 Insert the SW/OL reference tape

and enter the VTR STOP mode.

2 0 01 01 Set the data.

3 3 21 Check that the data is “02”.

(Note1)

4 3 01 0D Set the data, and press PAUSE

button.

5 3 02 Check that the data changes to

“00”.

6 3 03 Check that the data is “00”.

(Note2)

7 0 01 00 Set the data.

Note1: If the data of page: 3, address: 21 is “72”, the tape top being played.

After playing the tape for 1 to 2 seconds, stop it, perform step 4

and higher.

Note2: If bit 0 of the data is “1”, the even channel is defective. If bit 1 is

“1”, the odd channel is defective. Contents of the defect is written

into page: C, addresses: 10 and 12. See the following table. (For

the bit values, refer to “5-4. SERVICE MODE”, “4-3. 3. Bit value

discrimination”.)

When the even channel is defective

Data of page: C, Contents of defect

address: 10

EE Writing into EEPROM (IC502) is defective

E8 Adjustment data is out of range

E7 No data is returned from IC301 (CAIN)

When the odd channel is defective

Data of page: C, Contents of defect

address: 12

EE Writing into EEPROM (IC502) is defective

E8 Adjustment data is out of range

E7 No data is returned from IC301 (CAIN)

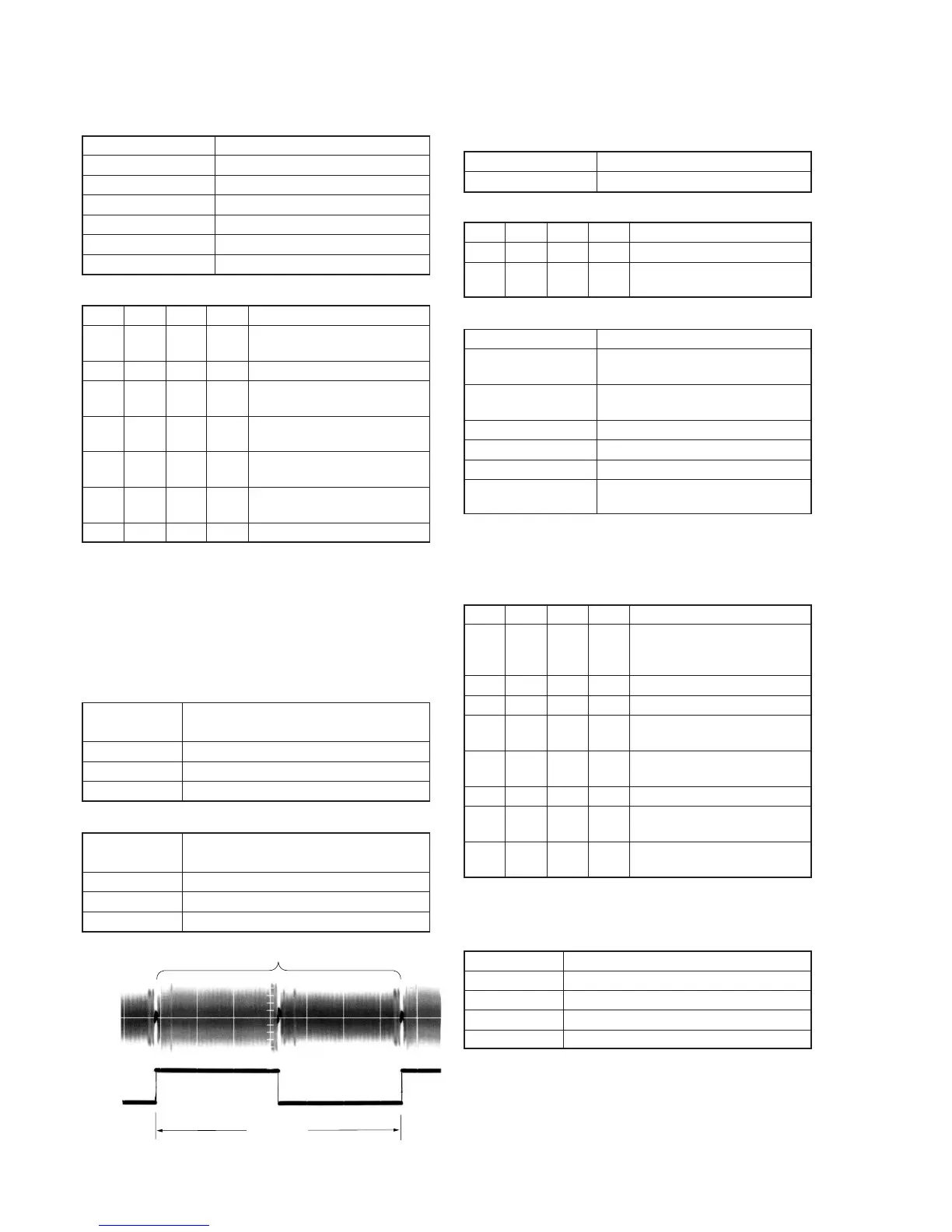

5. AGC Center Level and APC & AEQ Adjustment

5-1. Preparations before adjustments

Mode Camera recording

Subject Arbitrary

Adjusting method:

Order Page

Address

Data Procedure

1 2 30 40 Set the data.

2 Record the camera signal for

three minutes.

5-2. AGC Center Level Adjustment (VC-242 Board)

Mode Playback

Signal Recorded signal at “Preparations

before adjustments”

Measurement Point Pin 2 of CN007 (RF MON) (Note 1)

Ext. trigger: Pin 3 of CN007 (SWP)

Measuring Instrument Oscilloscope

Adjustment Page C

Adjustment Address 1E

Specified Value The data of page: 3, address: 03 is

“00”

Note 1: Connect a 75Ω resistor between Pin 2 and Pin 1 (GND) of

CN007.

75Ω resistor (Parts code: 1-247-804-11)

Adjusting method:

Order Page

Address

Data Procedure

1 Playback the recorded signal at

“Preparations before

adjustments”

2 0 01 01 Set the data.

3 3 33 08 Set the data.

4 Confirm that the playback RF

signal is stable. (Fig. 5-3-5.)

5 3 01 23 Set the data, and press PAUSE

button.

6 3 02 Check that the data is “00”.

7 3 03 Check that the data is “00”.

(Note2)

8 Perform “APC & AEQ

Adjustment”.

Note2: If the data of page: 3, address: 03 is other than “00”, adjustment

has errors. (Take an appropriate remedial measures according to

the errors referring to the following table.)

Data Contents of defect

20 Perform re-adjustment. (Note 3)

30 The machine is defective

40 Perform re-adjustment. (Note 3)

50 The machine is defective

Note 3: If this data is displayed twice successively, the machine is defective.

6.7 msec

PB RF signal is stable

Pin

3

Pin

2

Fig. 5-3-5.

Loading...

Loading...