10

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

Fig. 13

CODE Letters A to D, general description of

bearing condition

LUB Degree of lubrication in the rolling

interface. Displayed with CODE A, B

COND Degree of damage to bearing surfaces.

Displayed with CODE B, C, D

When it registers a valid bearing signal, the A2010 will

evaluate the reading and display:

• a CODE describing general bearing condition,

consisting of the letter A, B, C, or D.

• a LUB number describing lubrication condition in

the rolling interface between load carrying rolling

elements and raceway.

• a COND number describing the mechanical state

of the load carrying bearing surfaces.

The LUB No. is shown together with CODE A and B.

The COND No. is shown together with CODE B, C,

and D.

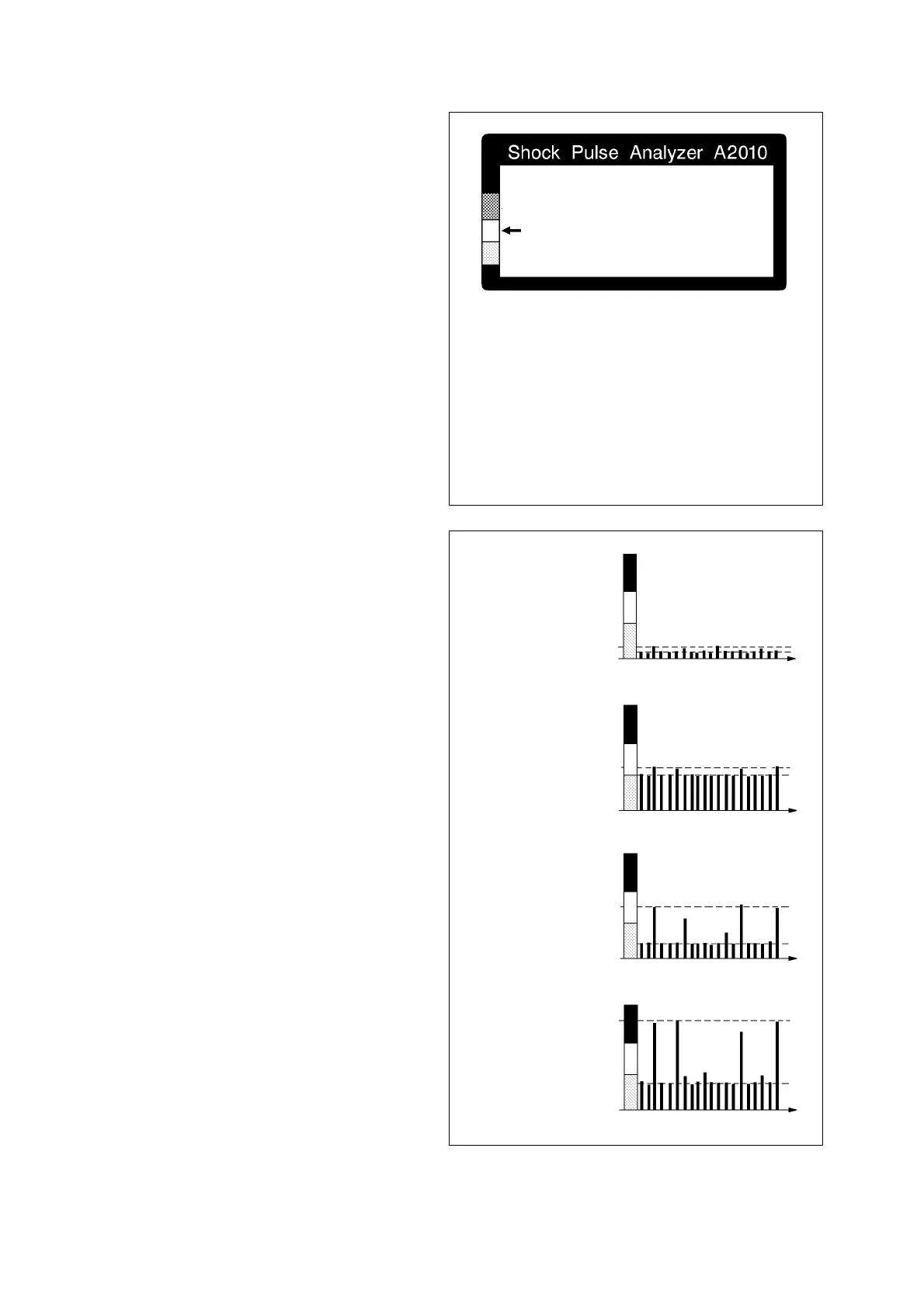

CODES for General Condition

CODE A means that the bearing is in good condition.

There is no detectable damage to the surfaces of the

load carrying parts, and no extreme lack of lubricant

in the rolling interface. Figure 14A shows a typical

shock pulse pattern from a good bearing: a low shock

level and a normal delta value.

CODE B indicates a dry running condition, causing an

high HR value and a low delta value (figure 14B). The

lubricant is not reaching the rolling interface, which

can have several causes, e.g. lack of lubricant supply

to the bearing, low temperature in a grease lubri-

cated bearing, or a heavy overload due to misalign-

ment, tight fit, deformed housing, etc.

CODE C is displayed when the instrument detects an

increased shock pulse level with a large delta value

(figure 14C). This points to beginning surface dam-

age.

CODE D is displayed when the A2010 recognizes a

signal that is typical for bearing damage: a high shock

level with a large delta value (figure 14D). A contami-

nation of the lubricant by hard particles causes a

similar pattern.

The message of the codes is supported by an arrow

pointing at the green - yellow - red scale beside the

display:

green - good condition (CODE A)

yellow - reduced condition (CODE B, C)

red - bad condition (CODE D).

Evaluated Shock Pulse Readings

BEARING TEST

CODE B Acc 3/3

LUB 0 LR 24

COND 28 HR 22

CODE A

Good condition

CODE B

Dry running

CODE C

Reduced condition

CODE D

Bearing damage

Fig. 14

Loading...

Loading...