4

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

The condition monitoring functions of the A2010 are

based on two widely used measuring techniques:

• SPM’s patented Shock Pulse Method for bearing

monitoring

• broad band vibration velocity measurement

according to ISO 2372.

The A2010 requires few input data and allows an

instant interpretation of machine condition by supply-

ing:

• a direct indication of machine vibration and

bearing condition in terms of good - reduced -

bad

• a digital display of lubrication condition data

(LUB No.) and damage severity readings

(COND No.) for bearings

• vibration severity readings in mm/s RMS

• contact and non-contact measurement of rpm

and peripheral speed.

Shock Pulse Analyser A2010 is the direct successor to

SPM’s Bearing Analyzer BEA-52. It’s data can be fed

into SPM’s computer programs for bearing analysis.

As a vibration meter and tachometer, the A2010 is

comparable with SPM's two portable instruments VIB-

10 and TAC-10.

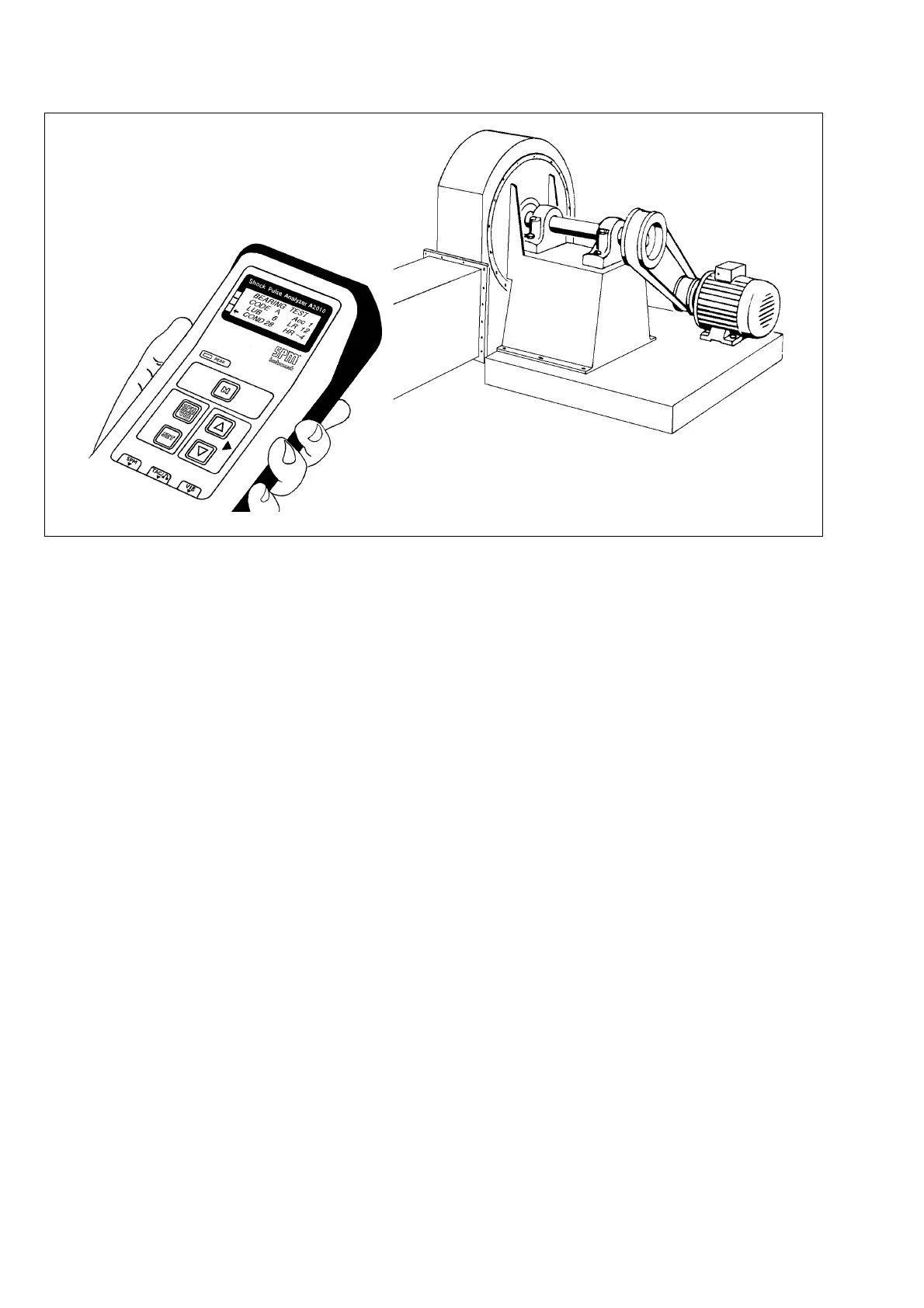

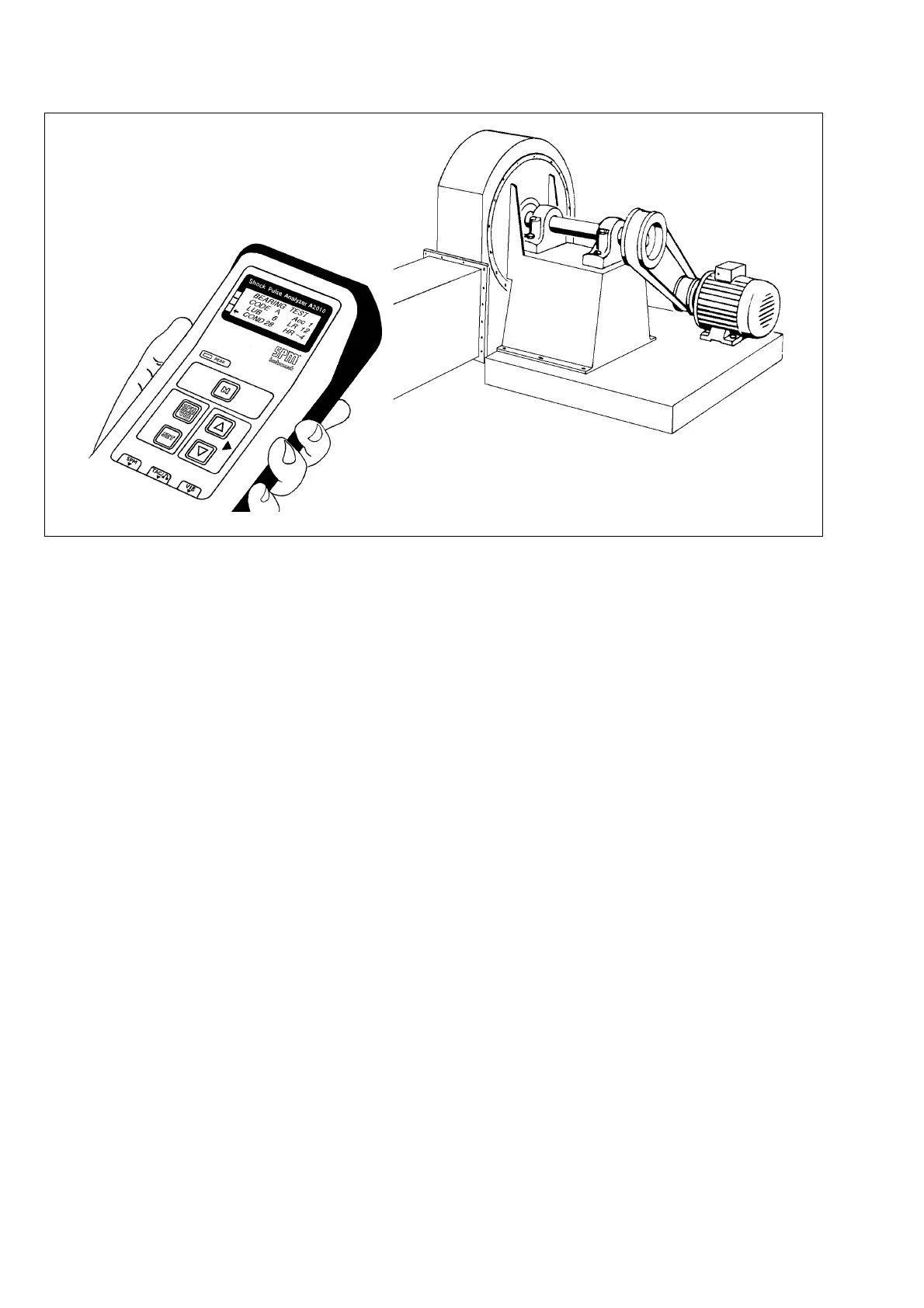

Shock Pulse Analyzer A2010 combines the functions

of a shock pulse meter, a vibration meter, and a

tachometer. It is used to check the operating condi-

tion of rotating machines, in order to detect mechani-

cal faults and supply data for effective preventive

maintenance.

With the A2010, maintenance personnel can monitor

all significant aspects of mechanical machine condi-

tion:

• the mechanical condition of rolling bearings

(bearing damage development)

• the lubrication condition of rolling bearings

(lubricant film in the rolling interface)

• general machine condition (the effect of structural

looseness, misalignment and out-of-balance on

machine vibration).

The purpose of systematic condition monitoring is:

• to avoid unnecessary overhauls of machines in

good working order

• to avoid routine replacements of serviceable

bearings

• to improve the life expectancy of rolling bearings

by optimizing their lubrication

• to detect trouble spots in time for planned

repairs and replacements, avoiding both

breakdowns and unnecessary production stops.

Machine Condition Monitoring

Bearing condition

Machine vibration

Rotational speed

Fig. 1

Loading...

Loading...