14

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

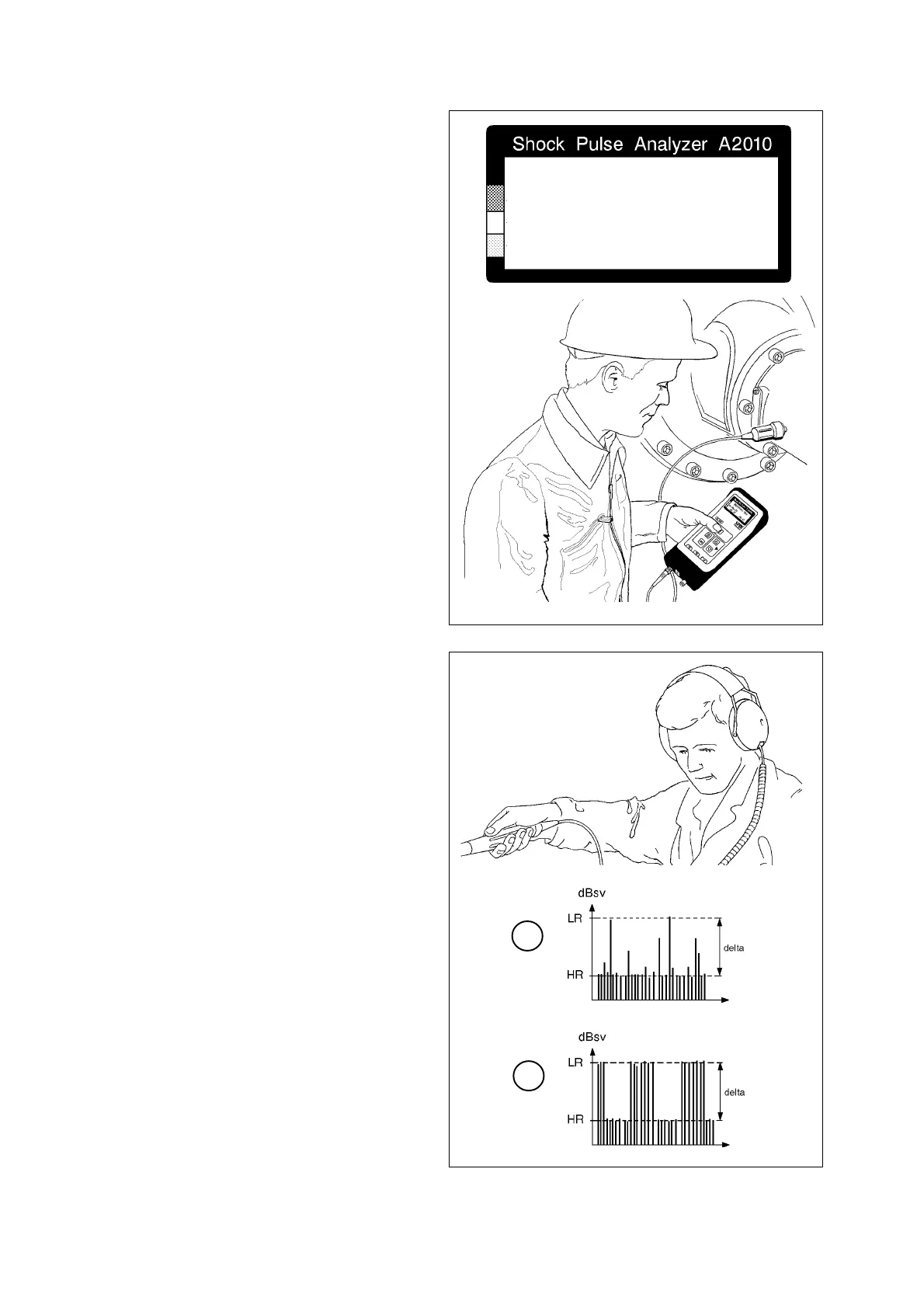

Taking Shock Pulse Readings

Pressing any key will start the A2010 in the last used

measuring mode. The SPM/VIB key changes the mode

from vibration to shock pulse monitoring.

The SET key allows to input or change NORM and

TYPE number, to set a COMP number and the number

of measuring cycles to be accumulated. Pressing the

M key will switch from the SET to the measuring

mode.

The user then connects the transducer to the measur-

ing point and presses the M key once. While the

instrument goes through the programmed number of

measuring cycles, the peak indicator blinks and the

bearing data are on the screen. The figure behind Acc

shows the number of completed measuring cycles.

The transducer type used is displayed in the bottom

right hand corner of the screen (fig. 22).

After completing the measurement, the A2010 dis-

plays the bearing’s shock values (LR and HR) together

with CODE, LUB, and COND. An arrow points at the

condition scale, green field for CODE A, yellow for B

and C, red for D.

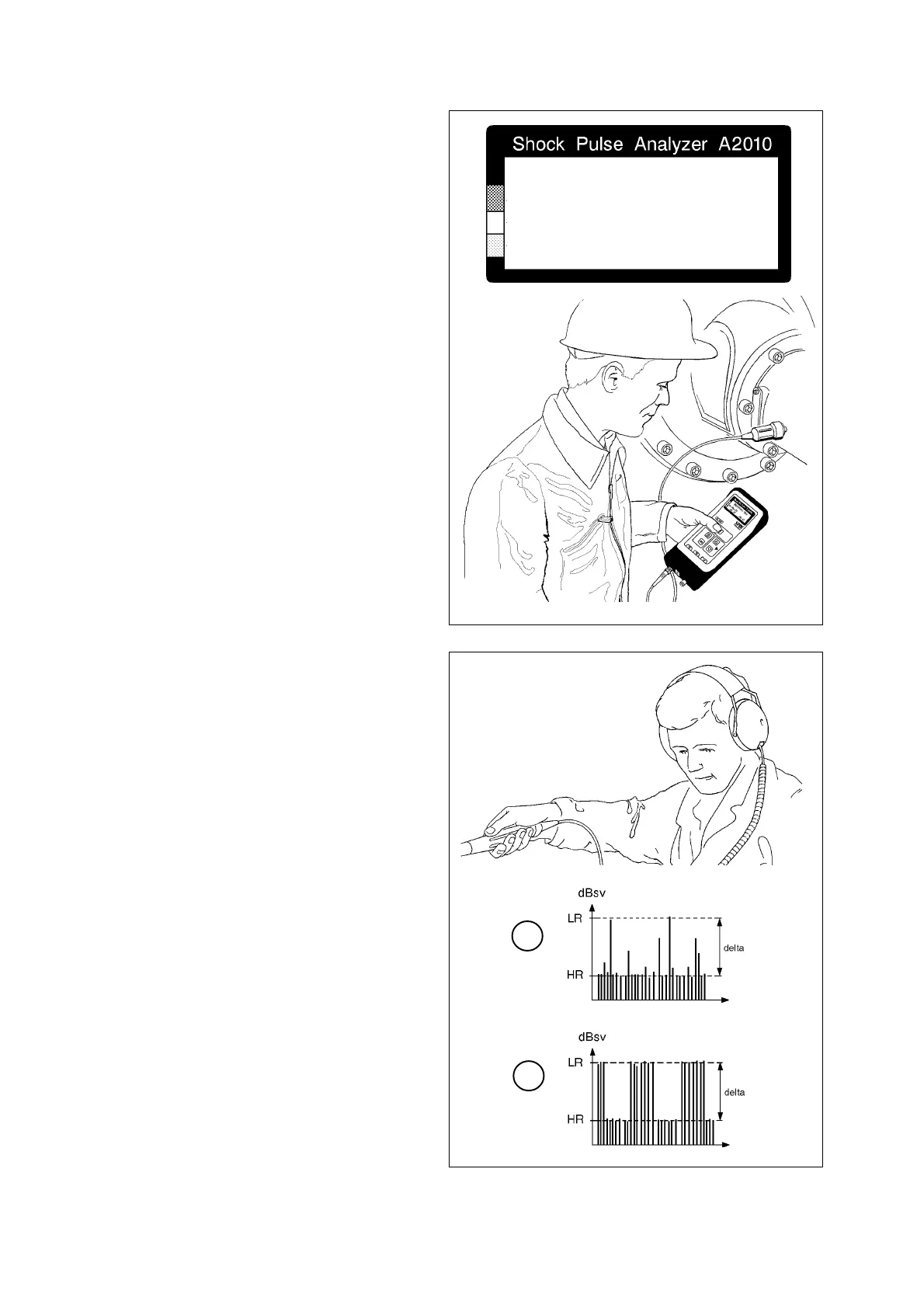

The Earphone Mode

The earphone mode is a help function for a further

evaluation of shock pulse readings indicating bad bear-

ing condition. It allows the user to listen to the rhythm

of the shock pulses and to determine their probable

origin and cause.

The transducer has to be connected to the measuring

point while the earphones are used. The arrow keys

control the measuring threshold: ”UP” moves it up

the dB

SV

scale, ”DOWN” lowers the threshold. The

peak indicator is active and blinks if there are shock

pulses above the set level.

A machine can contain shock pulse sources other than

the bearings. Mostly, these can be easily identified by

their characteristic sound pattern. Single shock pulses

are heard as single sound pulses, while the shock

pulses at the HR level are heard as a continuous tone.

Figure 23 shows two typical patterns:

A A damaged bearing - strong, irregular, single

peaks well above the HR level

B Scraping or rubbing machine parts - a shower of

peaks at regular intervals.

Fig. 23

A

B

MEASURING . .

NORM 32 Acc 0 / 3

TYPE 1

COMP 0 TRA

Fig. 22

Loading...

Loading...