11

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

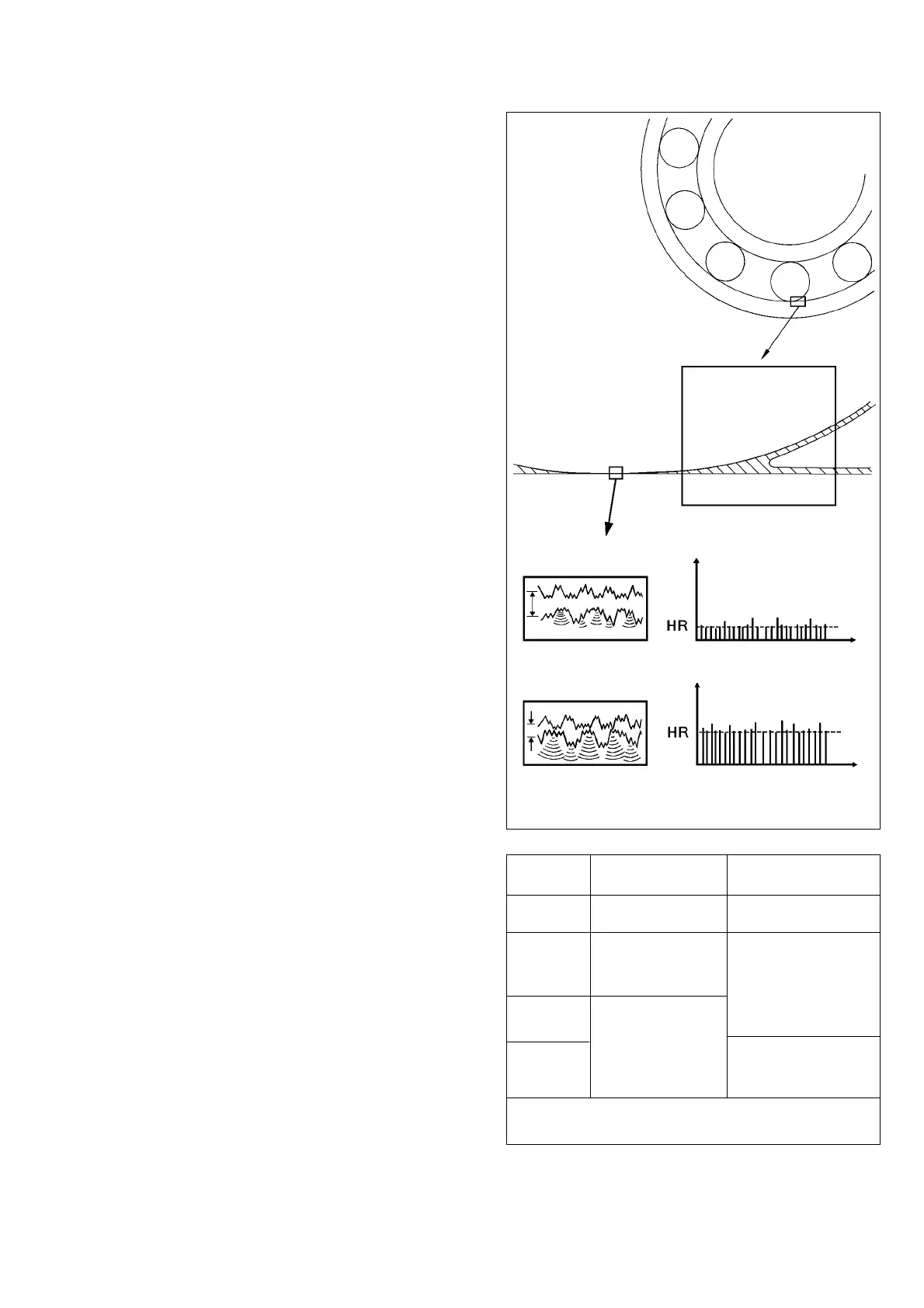

The most important influence on the service life of a

bearing is its lubrication, or, to be precise, the lubri-

cant film between the load carrying rolling elements

and the raceway. By preventing or inhibiting metallic

contact between the loaded bearing parts, the lubri-

cant film reduces the local peak stress in the rolling

interface. The greater the lubricant film thickness, the

more even the load distribution in the contact area,

and the better the fatigue life of the bearing.

Irregularities in the bearing surfaces will always cause

pressure variations in the contact area, and thus shock

pulses, even when metallic contact is prevented by a

separating lubricant film (figure 15A). A thinner film

will result in an increase of the bearing's HR value

(figure 15B).

By measuring the variations in the shock pulse pat-

terns of undamaged bearings, the A2010 can evalua-

te the effect of the lubricant film, and display a LUB

No. which is directly proportional to film thickness.

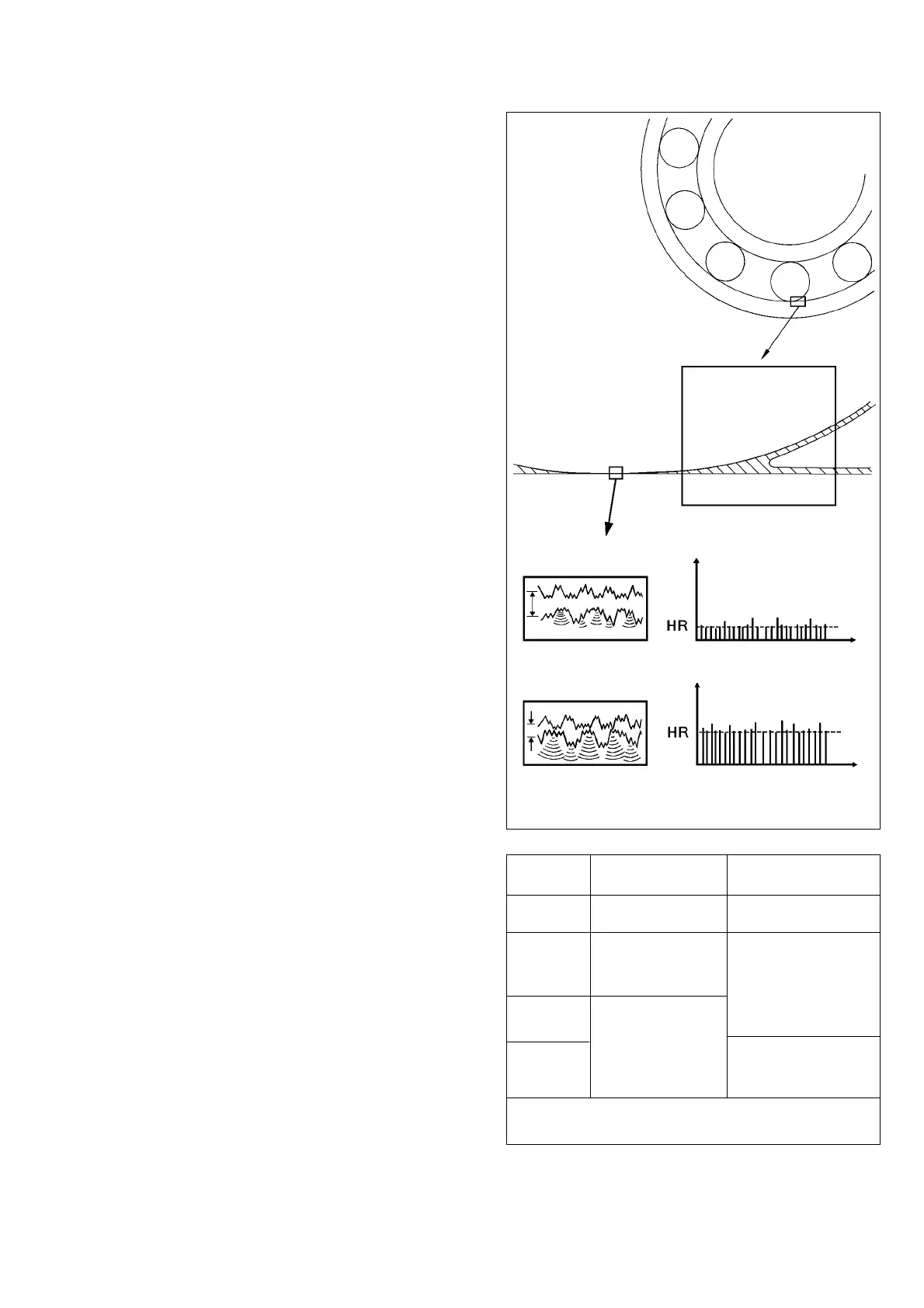

LUB No. for Ball and Roller Bearings

The LUB No. is displayed together with CODE A and

B. LUB No. 0 means dry running condition. The inter-

pretation of LUB Nos. between 1 and 4 depends on

the bearing type. For ball bearings, LUB Nos. greater

than 2 mean full lubrication (a load carrying oil film).

For roller bearings, a LUB No. greater than 4 indicates

full lubrication.

The term boundary lubrication implies that part of the

load is carried by metal to metal contact.

Factors Influencing Lubrication

The amount of lubricant in or supplied to the bearing

is only one of the many factors that determine lubri-

cant film thickness. Lubricant type and the bearing's

rpm are of great importance, but also the geometry

of bearing parts and housing, as well as the load put

on the bearing by alignment and fitting.

Lubrication Condition

Rolling

interface

A

B

Fig. 15

LUB No. Ball bearings Roller bearings

0 Dry running Dry running

1 to 2 Boundary Boundary

lubrication lubrication

3 to 4 Full lubrication

> 4 Full lubrication

Fig. 16 LUB No. for ball and roller bearings

Loading...

Loading...