61

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

Vibration at the measuring point should be repre-

sentative of the overall vibration pattern of the ma-

chine. The forces involved are usually transmitted

through the bearings and their housings to the ma-

chine foundation. Consequently, measuring points

should be located on or near the bearing housings.

Machine guards, cover panels and other parts which

are considerably less stiff than the main structure are

not suitable as measuring points.

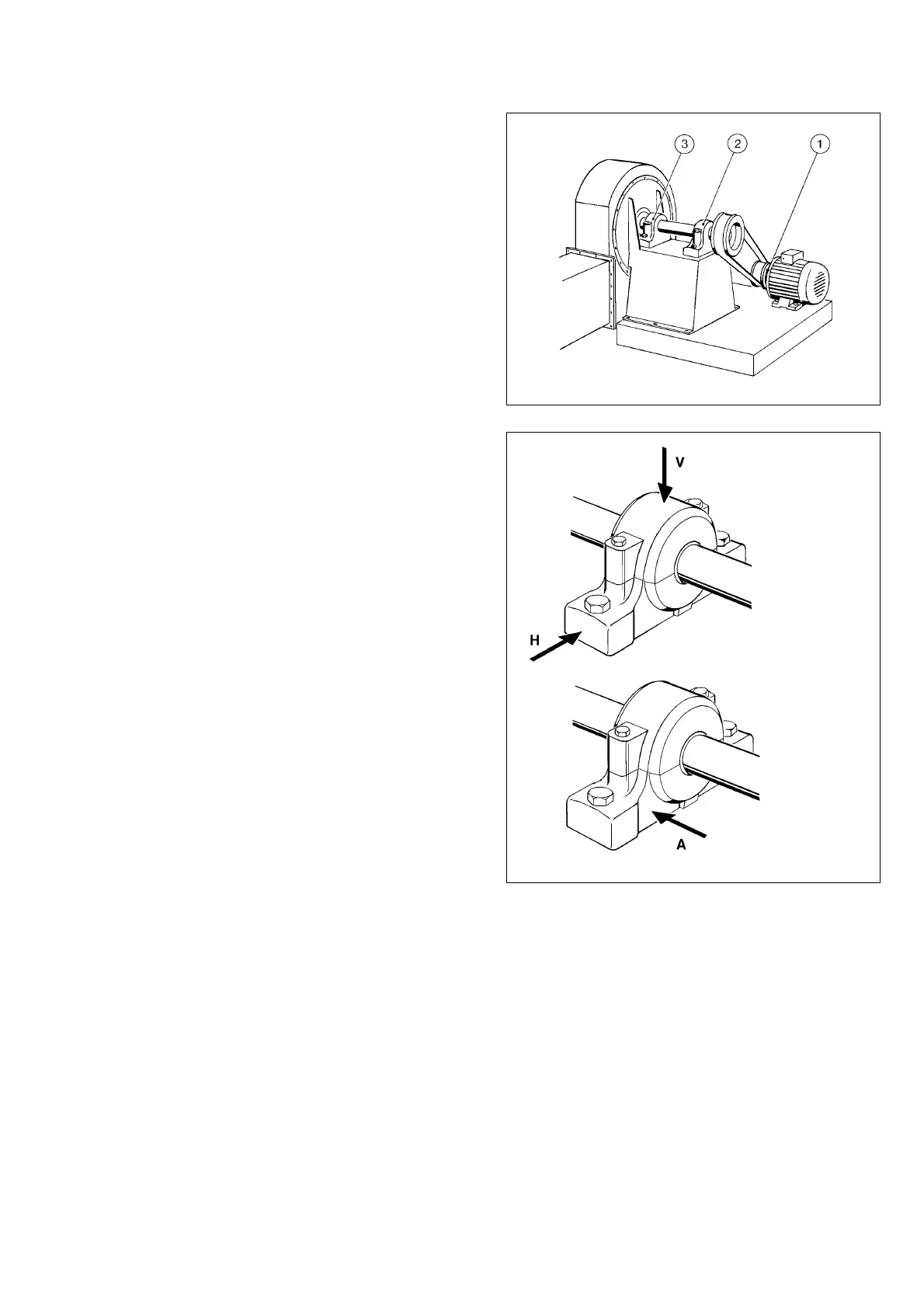

Generally speaking, the more measuring points cho-

sen, the easier it is to locate a specific mechanical

problem. Consider a fan belt driven from an electric

motor. Measurements taken on the fan bearing (3)

will primarily give information on fan balance. If out-

of-balance is the main problem, measuring on that

bearing will be sufficient. To be able to make an

adequate assessment of the mechanical state of the

whole machine, one should also measure on the drive

end bearing (2) and on the motor (1).

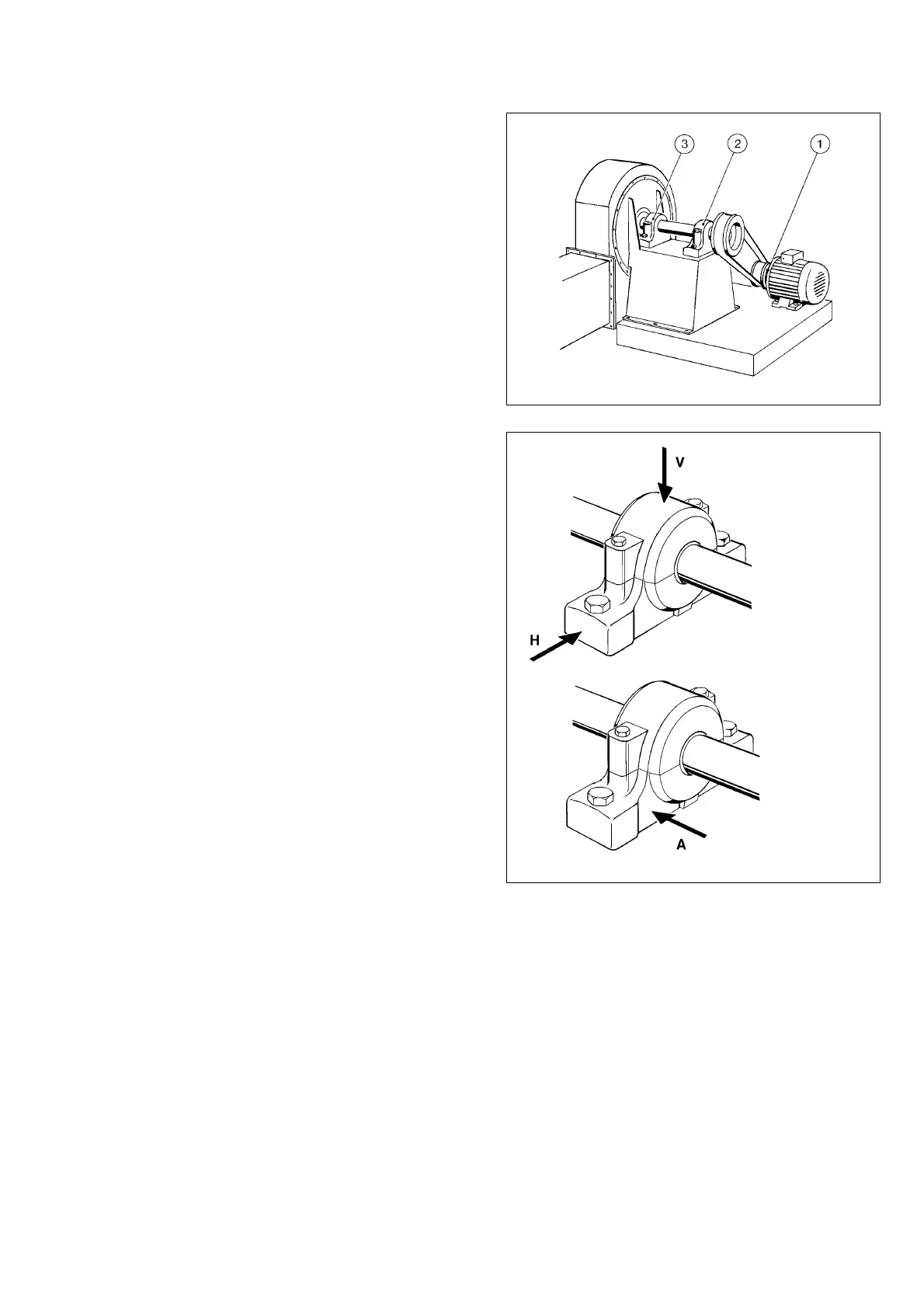

Direction of Measurement

Out-of-balance forces rotate with the shaft and cause

radial vibration acting in all directions within the plane

of rotation.

Axial vibration, along with the line of the shaft, is

normally caused by faulty alignment, i.e. badly assem-

bled couplings or bent shafts.

Normal practice is to take readings in three directions

at each measuring point: vertical (V), horizontal (H)

and axial (A). Of the two radial measurements, a read-

ing in the vertical direction tends to give information

about structural weakness. The horizontal reading is

most representative of balance conditions.

Mark and Prepare

The exact spot on the machine where the transducer

is placed should be clearly marked and used each

time a reading is taken. Relatively small changes in

the measuring point can cause misleading changes in

the measured value and make trend analysis difficult.

The transducer should be attached with the magnetic

base to a smooth, flat surface. Spot-face the contact

surface if necessary.

Measuring Points for Vibration

Fig. 7

Hand-held Probe

With the probe tip attached, the transducer can be

used as a hand-held probe. Hand-held probes are

widely used for fast checks, and there is no need to

prepare the measuring point. Note, however, that the

overall stiffness is poor, which can lead to gross meas-

uring errors. Using a hand-held probe requires prac-

tice, and repeatable results cannot be guaranteed.

Fig. 8

Axial

vibration

Radial

vibration

Loading...

Loading...