60

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

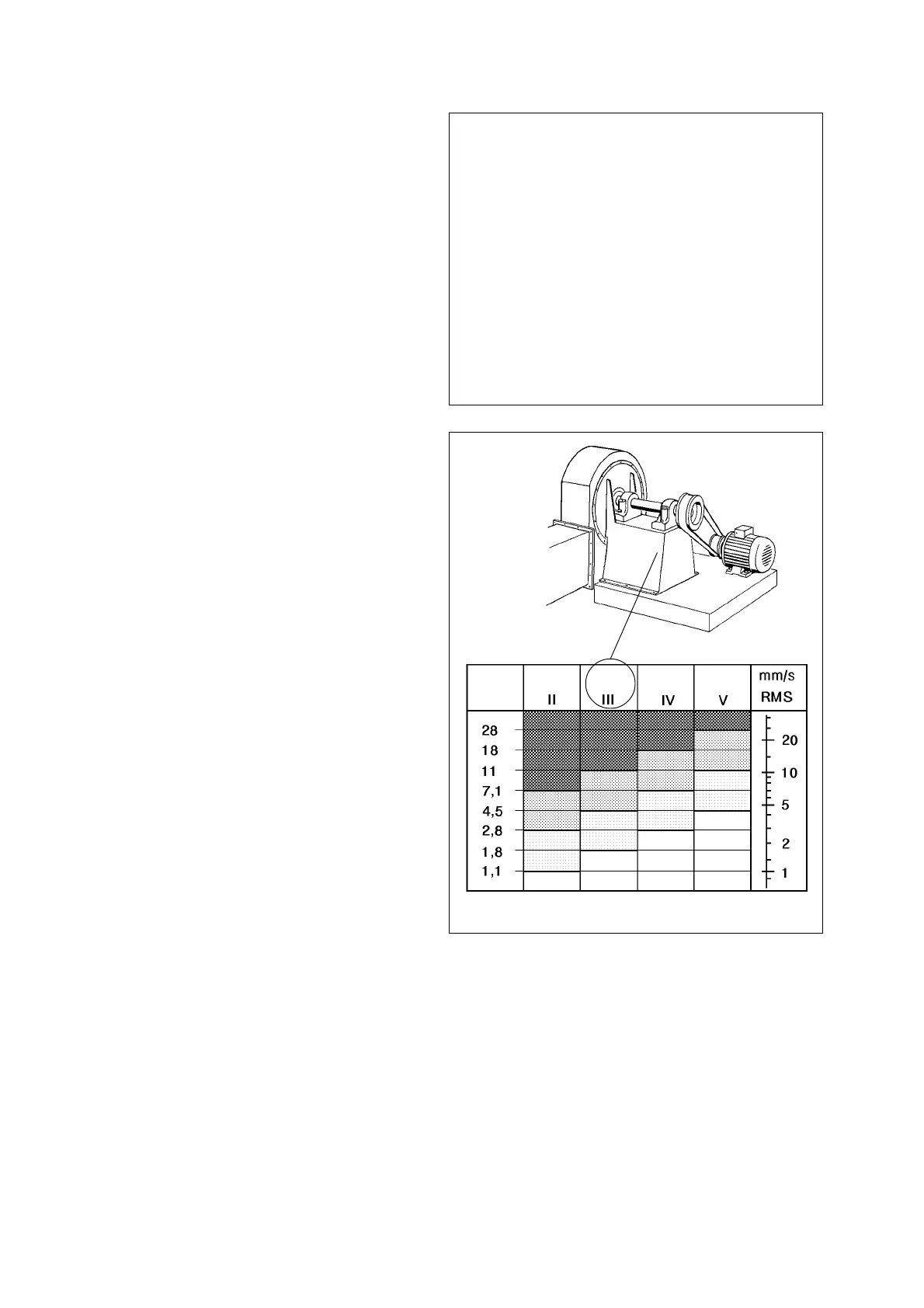

Class Class Class Class

Limits

Preparations for Systematic Monitoring

Preparations:

1 Select suitable machines

2 Define the vibration class of each machine

3 Select one or more measuring points

4 Mark and prepare the measuring point(s)

5 Prepare a follow-up form for each machine

The general preparations for systematic vibration moni-

toring are listed in figure 5.

Suitable Machines

Periodic vibration monitoring with the A2010 is suit-

able for any machine unit which is not subject to

sudden, dangerous increases of the vibration level.

A continuous vibration monitoring system should be

installed on fans where the shedding of a dirt layer or

a breaking blade can lead to sudden out-of-balance.

Vibration Classes

There are three ways to determine the vibration class

of a machine:

1 Use the manufactures' specification of

acceptable vibration levels for their equipment as

a reference. Compare them with the ISO limit

values in figure 6 and select the suitable class.

2 Measure the vibration level when it is reasonably

sure that a machine is in good condition. Choose

a class where that reading falls into the upper half

of the ISO ”good condition” zone, or the lower

half of the ”acceptable condition” zone.

3 Classify the machines according to the ISO

definitions quoted on page 64.

Classification of machinery is largely a matter of expe-

rience because the definitions provided by the stand-

ards are deliberately loose. Most industrial plant be-

longs to vibration classes II, III and IV:

II Medium size machines without special

foundations

III Large machines on rigid foundations

IV Large machines on soft foundations.

For example, most smaller process pumps on a chemi-

cal plant would be Class II. A 100 kW ventilation fan

on a concrete base would be Class III. However, the

same fan fastened to the less rigid metal deck of a

ship could be considered as Class IV.

Fig. 5

Fig. 6

Class I refers to independent parts of machines, for

example electric motors up to 15 kW.

Classes V and VI are used for heavy reciprocating

prime movers and machines which are intended to

vibrate – for example vibrating screens.

Loading...

Loading...