16

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

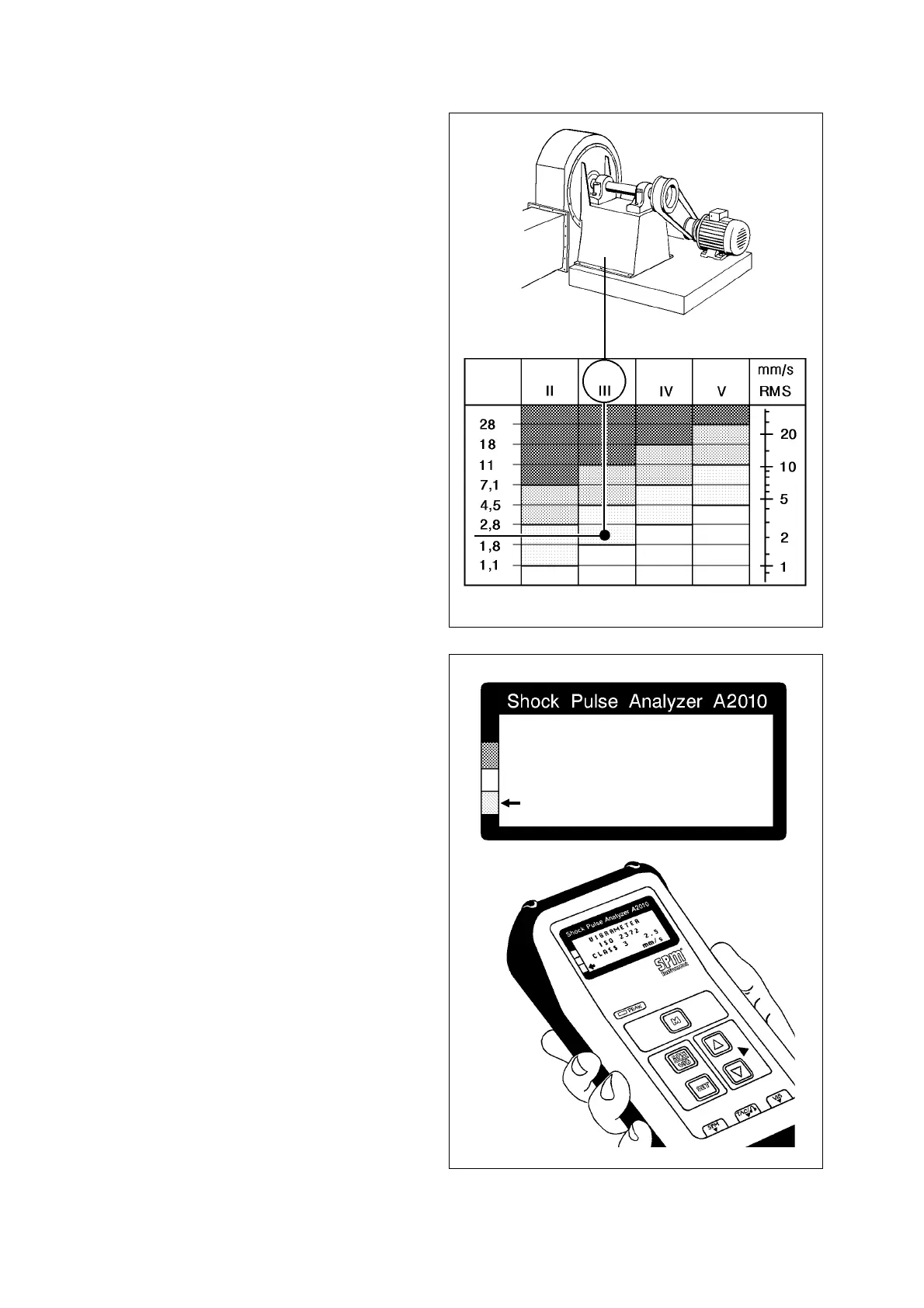

Excessive vibration has basically three causes: some-

thing is loose, misaligned, or out of balance. An expe-

rienced maintenance crew will normally find the cause

without a complex analysis, if it is notified that the

general vibration level is too high.

The acceptable vibration level depends on the size,

design, and function of the machine, as well as on the

stiffness of its foundation. ISO recommendation 2372

(likewise BS 4675 and VDI 2056) define vibration clas-

ses for various types of machines. The table in figure

26 shows the most common of the six classes and

their limit values.

In order to assess machine condition on the basis of

vibration severity measurements, one has to define

the normal vibration level of the machine, either ac-

cording to its vibration classing, the manufacturer’s

recommendations, or on the basis of measurements

when the machine is in good condition.

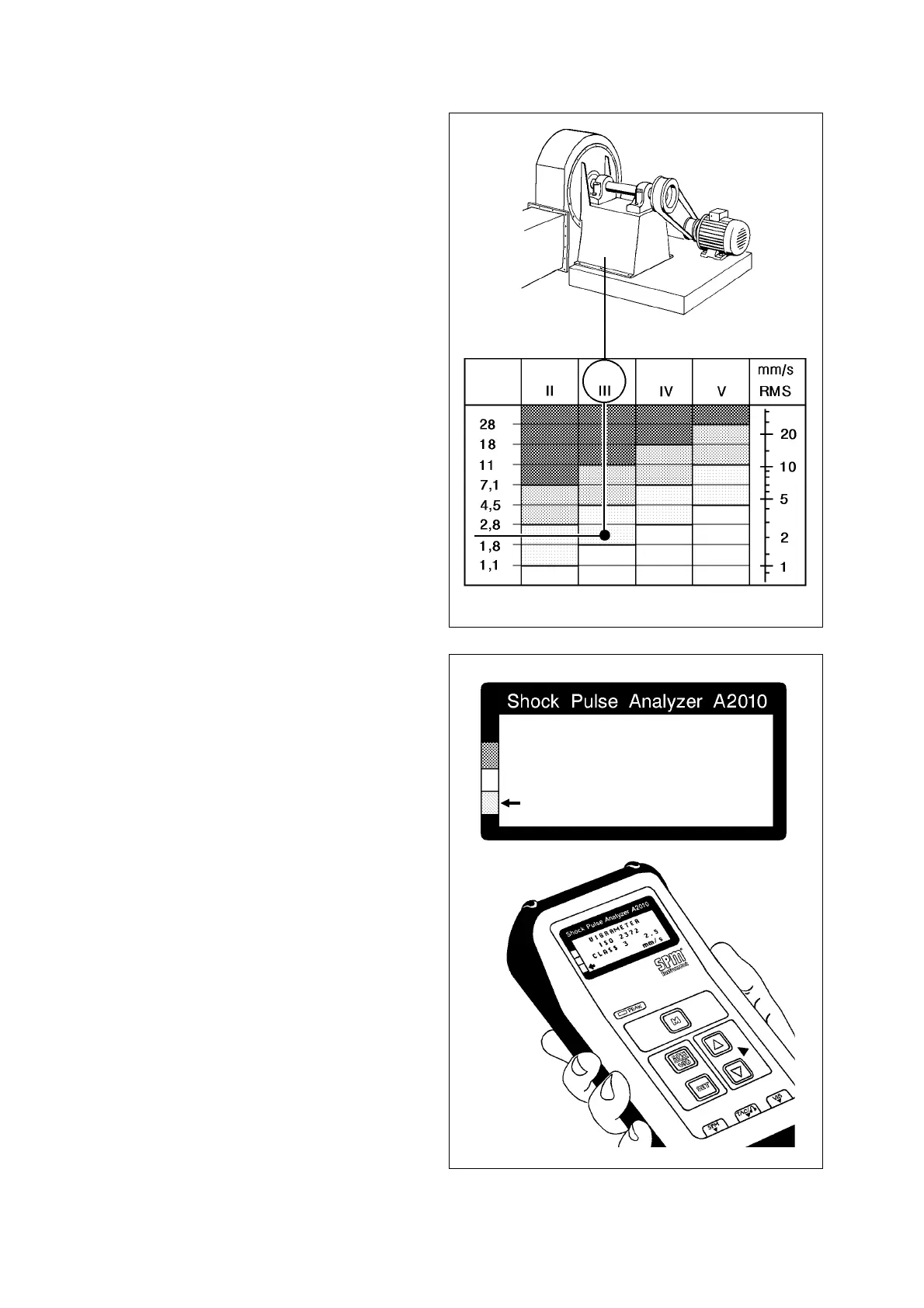

As an example, a 100 kW ventilation fan on a concrete

base would belong to class III. If the number 3 is input

prior to measurement, the A2010 will compare the

measuring result with the limit values for this class. An

arrow pointing at the condition scale will indicate

machine condition in terms of good - reduced - bad. If

no class number is input, the vibration severity value

will be shown without further evaluation.

Vibration measuring points are usually selected on

the bearing housings. The vibration transducer is sen-

sitive only along its main axis, in the direction it is

pointed.

This allows a limited analysis of the causes for excess-

ive vibration. Radial vibration, measured in the verti-

cal direction, gives information about structural weak-

ness, whereas a horizontal reading is most repre-

sentative of balance conditions. Axial vibration, along

the line of the shaft, is normally caused by faulty

alignment, badly assembled couplings or bent shafts.

Thus, readings from several measuring points in three

directions can usually give a good indication of the

nature and location of the maintenance problem.

Vibration Severity Measurement

Fig. 27

Fig. 26

Limits Class Class Class Class

VIBRAMETER

ISO 2372

CLASS 3 2.5

mm /s

Loading...

Loading...