36

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

Condition based maintenance implies that more time

and resources are devoted to condition monitoring

and less to emergency repairs, with the aim to achieve

an overall reduction of the total production costs.

This puts a heavy responsibility on the measuring

personnel – they have to find machine faults before

these cause trouble, and they should be able to present

a detailed fault analysis which allows fast repairs.

In the vast majority of cases, bearing condition moni-

toring with the A2010 is a simple, fast and easy job.

There are only two basic requirements for obtaining a

reliable condition reading:

• a correct measuring point, selected according to

SPM's rules

• correct NORM and TYPE numbers.

As with any condition evaluation method, there are

borderline cases and exceptions from the norm. In a

few cases, SPM measurements can be more difficult

because of:

• low r.p.m. and low or irregular load

• interference from other shock pulse sources

• very rapid damage development.

This manual emphasises the exceptional cases, where

extra care is needed to avoid a misinterpretation of

the measuring results. It also stresses the fact that

careful planning and efficient measuring routines are

the best means to save time, increase accuracy, and

avoid errors. The reason is obvious: while thousands

of successful routine measurements will pass unno-

ticed, a single unprevented bearing failure can have

very spectacular and costly results.

The recommended administrative routines are based

on long experience with the SPM method. They are

flexible in detail, and can be adapted to the existing

maintenance system.

Basically, an efficient condition monitoring system re-

quires:

• careful preparation to obtain reliable base data

for normal bearing and machine condition

• well planned routines for periodic data collection

• a thorough evaluation of any deviation from the

normal condition measurements.

General Remarks on System Planning

Fig. 1

Setting up an SPM system:

1 Select machine units

2 Establish measuring rounds

3 Define measuring intervals

4 Select measuring points

5 Choose measuring equipment

6 Install measuring equipment

7 Prepare follow-up forms

8 Record basic bearing data

9 Evaluate initial readings

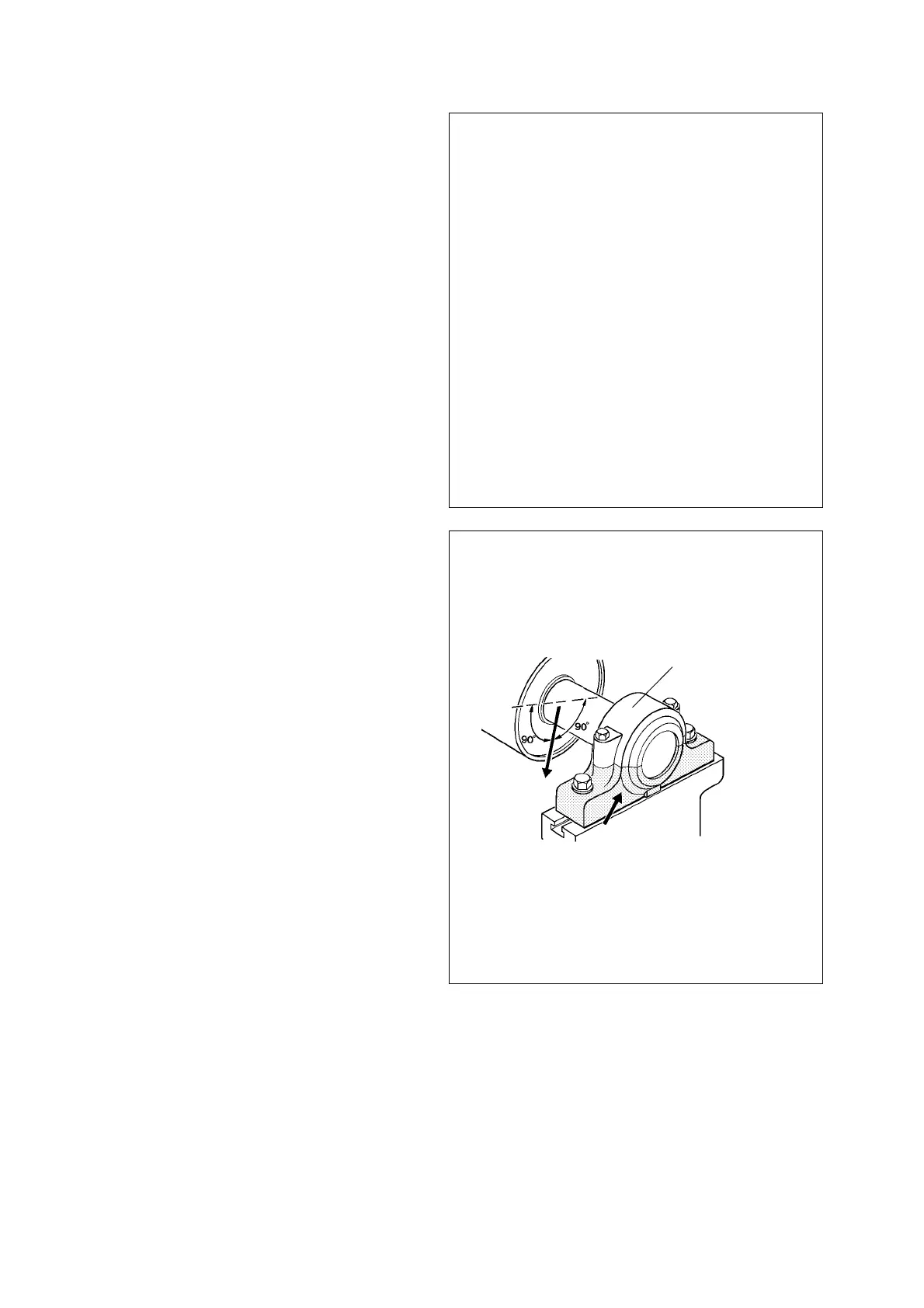

Fig. 2

Measuring

point

Load

Mean diameter

and r.p.m.

Loading...

Loading...