59

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

Measuring Vibration

If a fan is out of balance, it will shake at its speed of

rotation, i.e. move backwards and forwards once per

revolution. The number of vibrations per time unit is

the vibration frequency, measured in Hz (Hertz = cy-

cles per second).

The rotational speed of any piece of plant is known as

its fundamental frequency. For a fan with a speed of

1500 rpm, the fundamental frequency is 25 Hz (1500

rpm / 60 seconds).

In practice, machine vibration usually consists of many

different frequency components. For a general as-

sessment of machine condition one uses wide fre-

quency band measurements, that is all vibrations

within a large frequency range are measured simulta-

neously.

Cyclic movement can be measured and described in

three different ways, as displacement, acceleration,

or velocity.

Displacement means the actual distance the object

moves, usually measured in mm.

A part that is moving from rest, speeding up, slowing

down and stopping twice per cycle is accelerating and

decelerating continuously. Acceleration is measured

in g (1 g = 9.81 m/s

2

).

The third measuring parameter is the speed at which

the object moves, the vibration velocity. Velocity is

expressed in mm/s (in/s when imperial units are used).

Both acceleration and speed are constantly changing.

One can measure a peak value of either, but a mean

value often gives a better indication of the forces

involved in the movement. Most instruments measure

the RMS value (root mean square value) of the move-

ment.

Experience has shown, that the RMS level of vibration

velocity, measured over a frequency range of 10 to

1000 Hz, is most useful for general assessment of

machine condition. The technical term used is vibra-

tion severity, defined as above and displayed in mm/

s (or in/s) on the instrument.

Vibration severity is directly related to the energy

level of machine vibration, and thus a good indicator

of the destructive forces acting on the machine.

ISO Recommendation 2372

The essence of ISO recommendation 2372 is:

1 it states that vibration severity readings are useful

for a general assessment of machine condition.

2 it divides industrial machines into six vibration

classes and provides limit values for good,

acceptable, tolerable, and bad condition.

The A2010 is based on this recommendation, with the

exception that both good and acceptable condition

together are indicated on the green field of the condi-

tion scale.

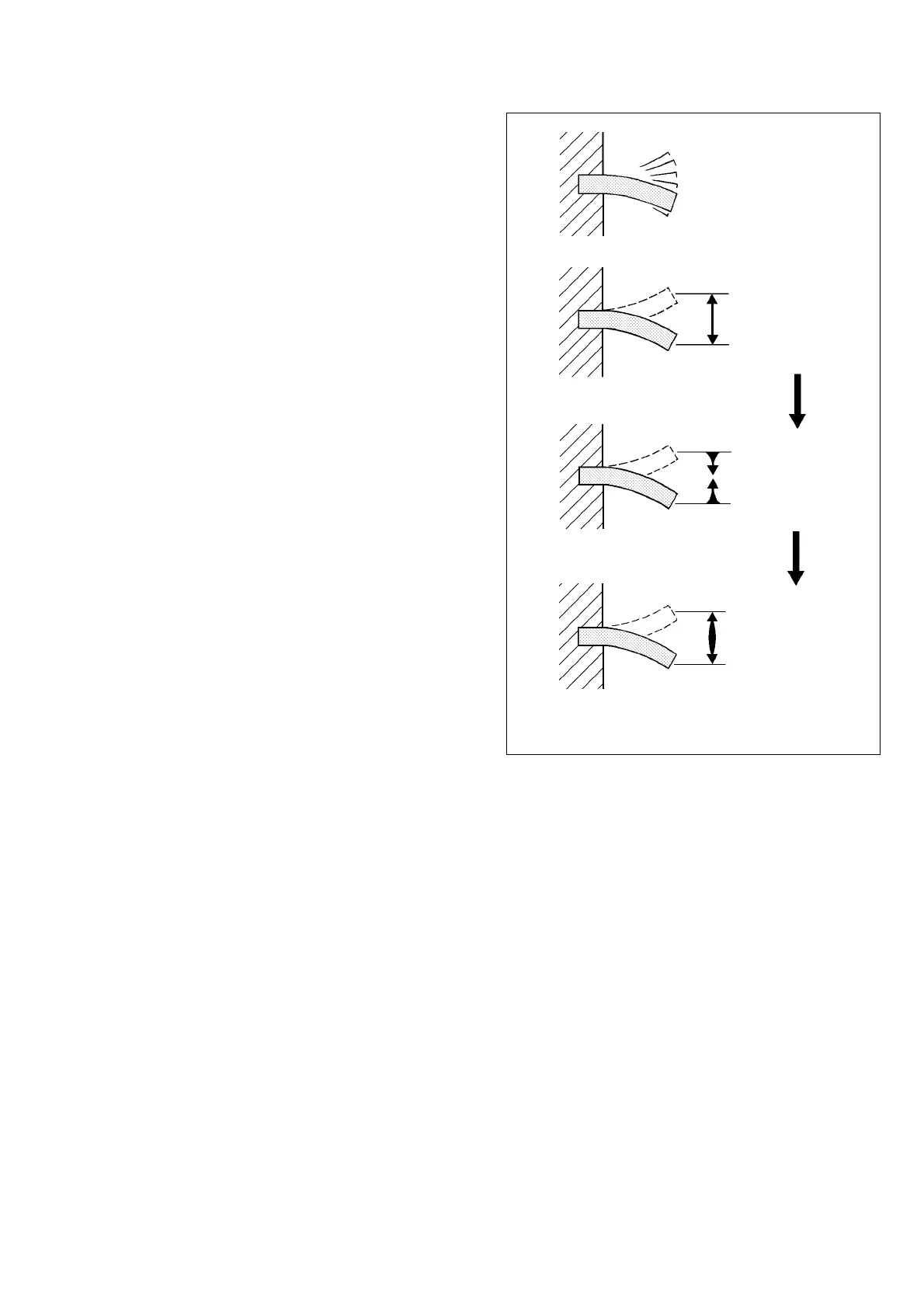

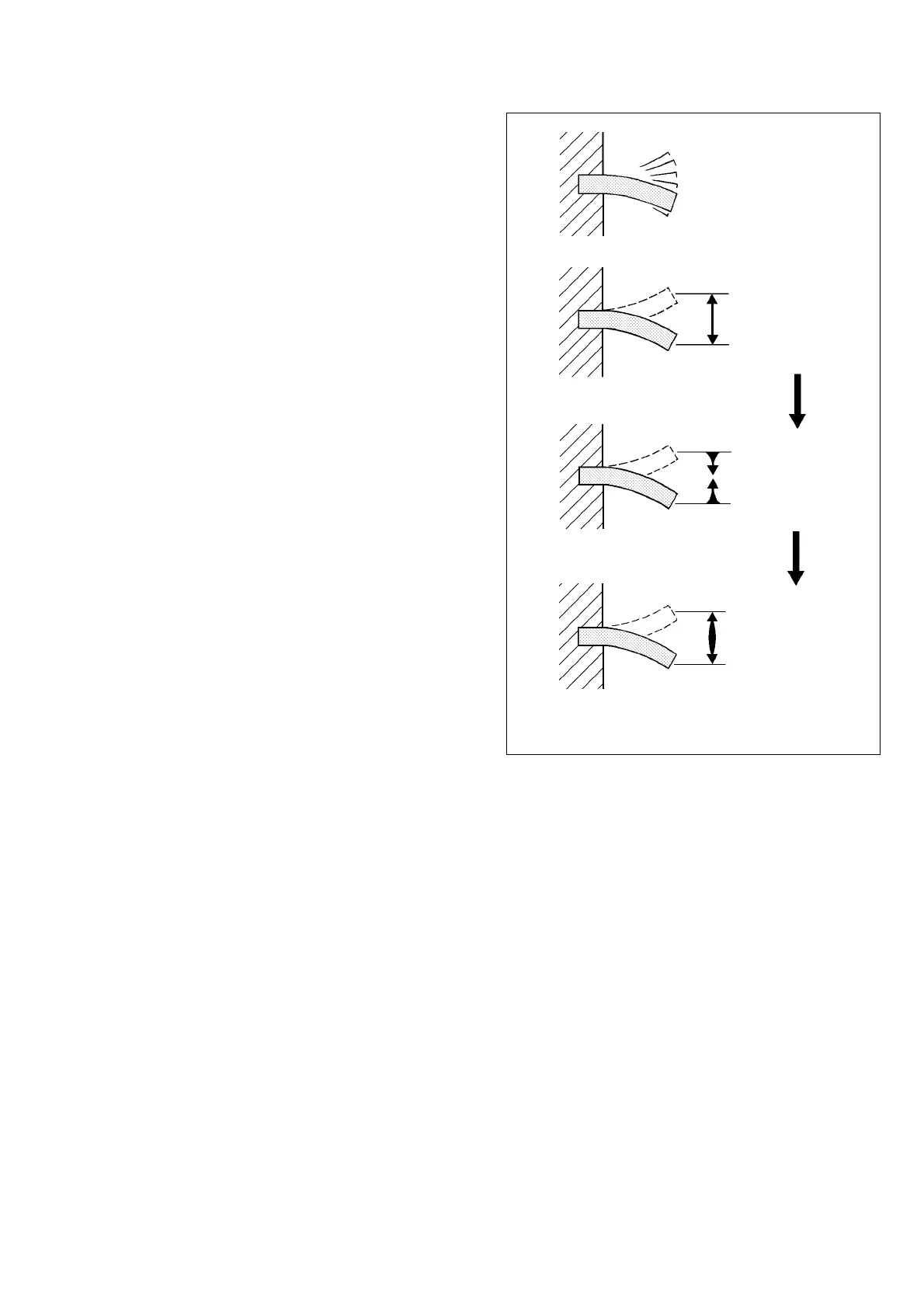

Frequency

Hz

+

Amplitude

mm

Acceleration

mm / s

2

Velocity

mm / s

Fig. 4

Loading...

Loading...