39

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

Unpredicted, very rapid damage development is rare.

Normally, surface damage develops slowly, over a

period of many months. These are the general guide-

lines for selecting the interval between periodic read-

ings:

• The bearings should be checked at least once

every three months.

• The bearings in critical machinery and heavily

preloaded bearings (e.g. spindle bearings) should

be measured more often than ”normal” bearings.

• The bearings should be measured more

frequently when their condition is unstable (rising

or irregular readings).

• Damaged bearings should be closely watched

until they can be replaced.

This implies that one has to allow time for extra checks

on bearings in dubious or bad condition.

Check Stand-by Equipment

Vibration and corrosion can damage the bearings in

stand-by machines. Check bearing condition each time

such machines are being tested or used.

Synchronize with Lubrication

It may be necessary to synchronize regreasing and

measuring intervals. Grease lubricated bearings should

not be measured until they have run for approxi-

mately one hour after regreasing (except when doing

a lubrication test, see page 52).

Keep in mind that bad bearing condition is often

connected with lubrication problems. For grease lu-

bricated bearings, a lubrication test usually provides

the final proof for bearing damage. Make sure that

the right type and quantity of grease is used.

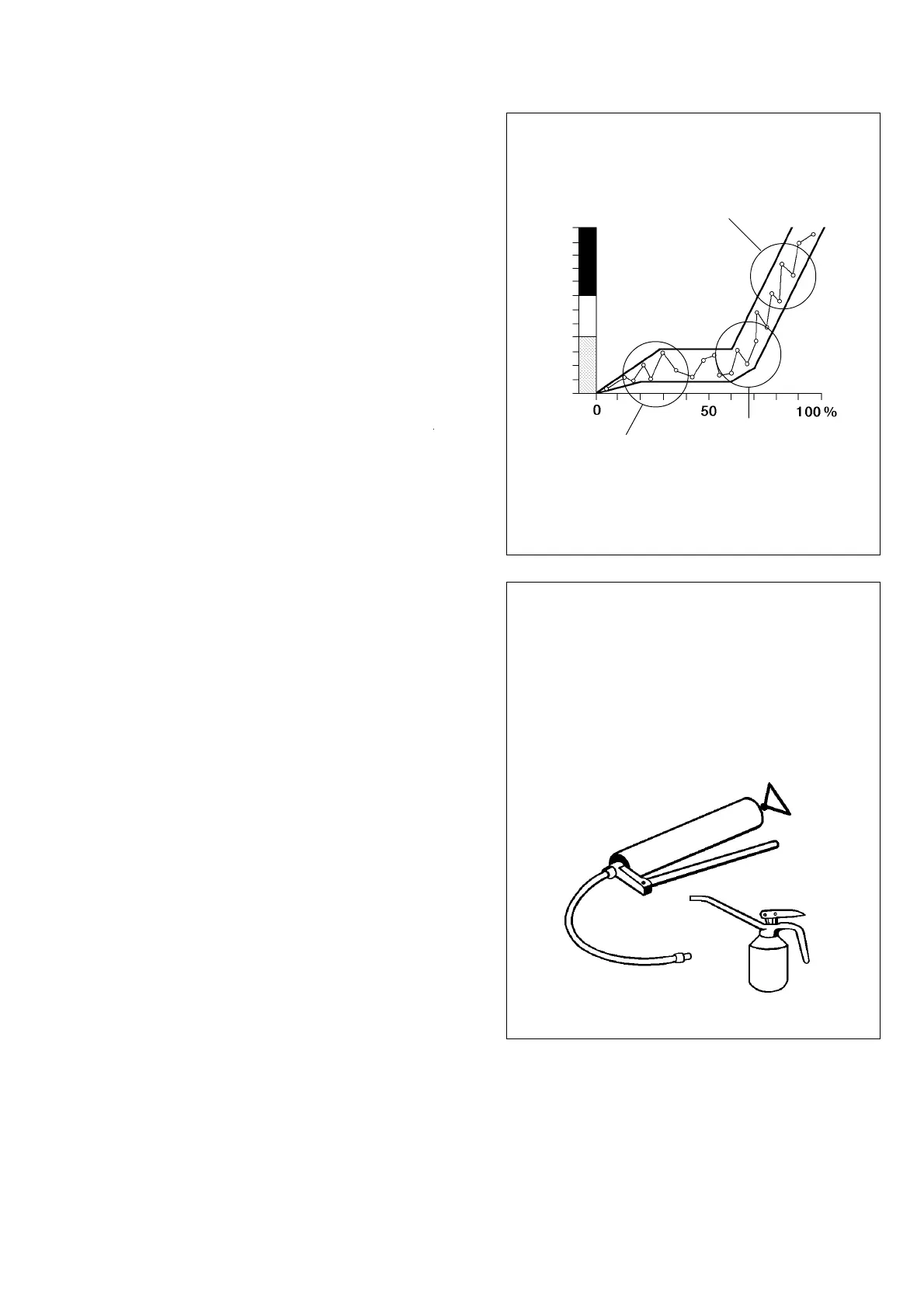

Measuring Intervals

Fig. 7

Measuring personnel

should know about:

• lubricant type

• maximum quantity

• lubricating intervals

1-3 months

several days,

one week

measure

often

Fig. 8

Loading...

Loading...