70

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

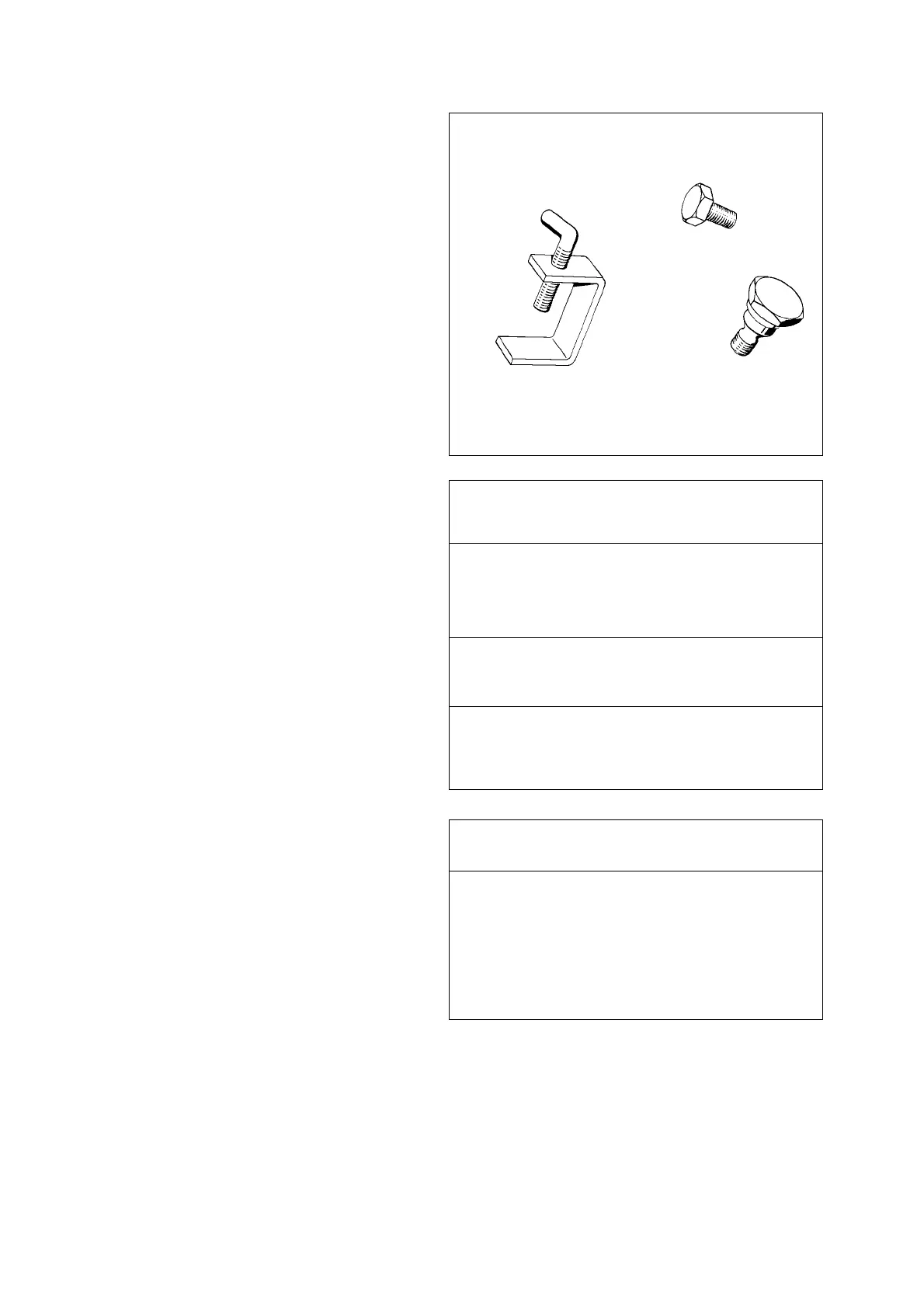

Fig. 24

For a trial weight one can use a screw or bolt of

known weight. A weight which can be clamped to the

rotor is even more practical.

The adjacent figure shows a few examples. For high

speeds, use smaller weights (below 10 grams).

Adding Correction Mass

Out-of-balance is normally corrected by welding or

brazing metal to the rotor. The adjacent table is in-

cluded to enable quick and easy manufacture of cor-

rection weights without the use of scales. Tolerances

within one gram should be sufficient.

Allowance should always be made for the weight of

the weld metal or brazing rod. A welding run weighs

about 0.5 grams for each 10 mm length.

Removing Mass

Removing mass at the heavy point of the rotor is also

possible, though less common for this kind of balanc-

ing work.

Mass is best removed by drilling one or more holes, at

the point defined by the calculated angle plus 180°.

Figure 26 lists the mass (for steel).

Trial Weights and Correction Mass

Fig. 25

Diameter Depth Mass

mm mm grams

460.6

4101.0

4121.2

862.4

8124.8

8249.6

SPM 32000

20 g

Trial weights

M8 x 12:

10 g

Fig. 26

Dimension, Grams Length for

Material

mm per mm 10 g, mm

Steel 6 x 6 0.28 35.0

6 x 12 0.56 18.0

6 x 24 1.13 9.0

12 x 24 2.26 4.5

Brass 6 x 6 0.26 38.0

6 x 12 0.53 19.0

12 x 12 1.06 9.5

Aluminium 6 x 6 0.10 100

6 x 12 0.20 50

12 x 12 0.39 25

Loading...

Loading...