17

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

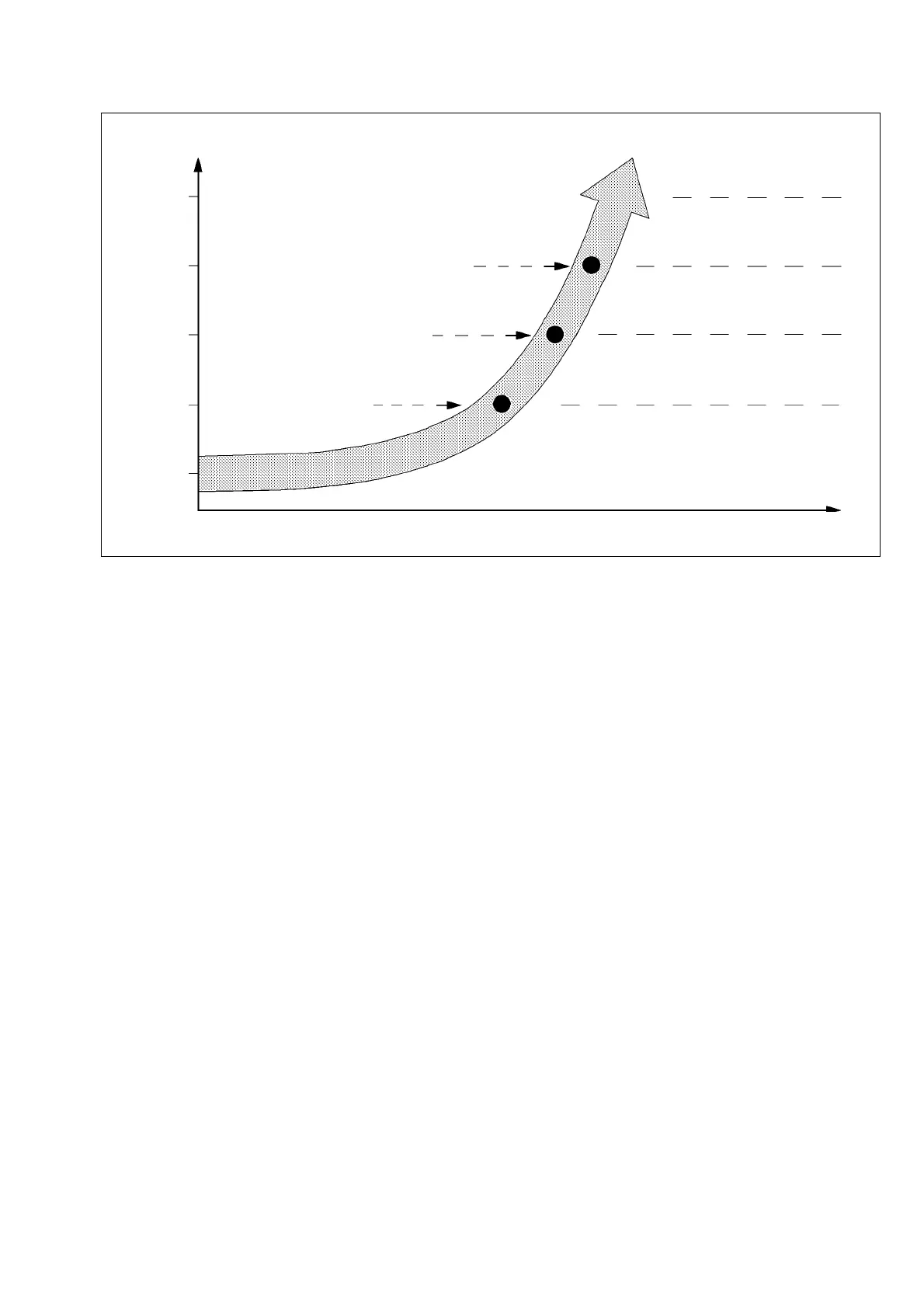

Fig. 28

Systematic vibration measurement includes recording

and trending, to be able to follow the gradual change

of machine vibration over longer periods of time.

The purpose is to obtain data for condition based

maintenance. Condition based maintenance, as op-

posed to periodic overhauls, is only carried out when

machine condition measurements show that repairs

are needed. This requires measurements at regular

intervals, and the recording and evaluation of the

results.

There are no general rules about how often vibration

should be measured. The intervals between readings -

a day, a week, perhaps a whole month - depends

wholly on the individual machine, its importance for

the plant, and on the rate of change in its vibration

level.

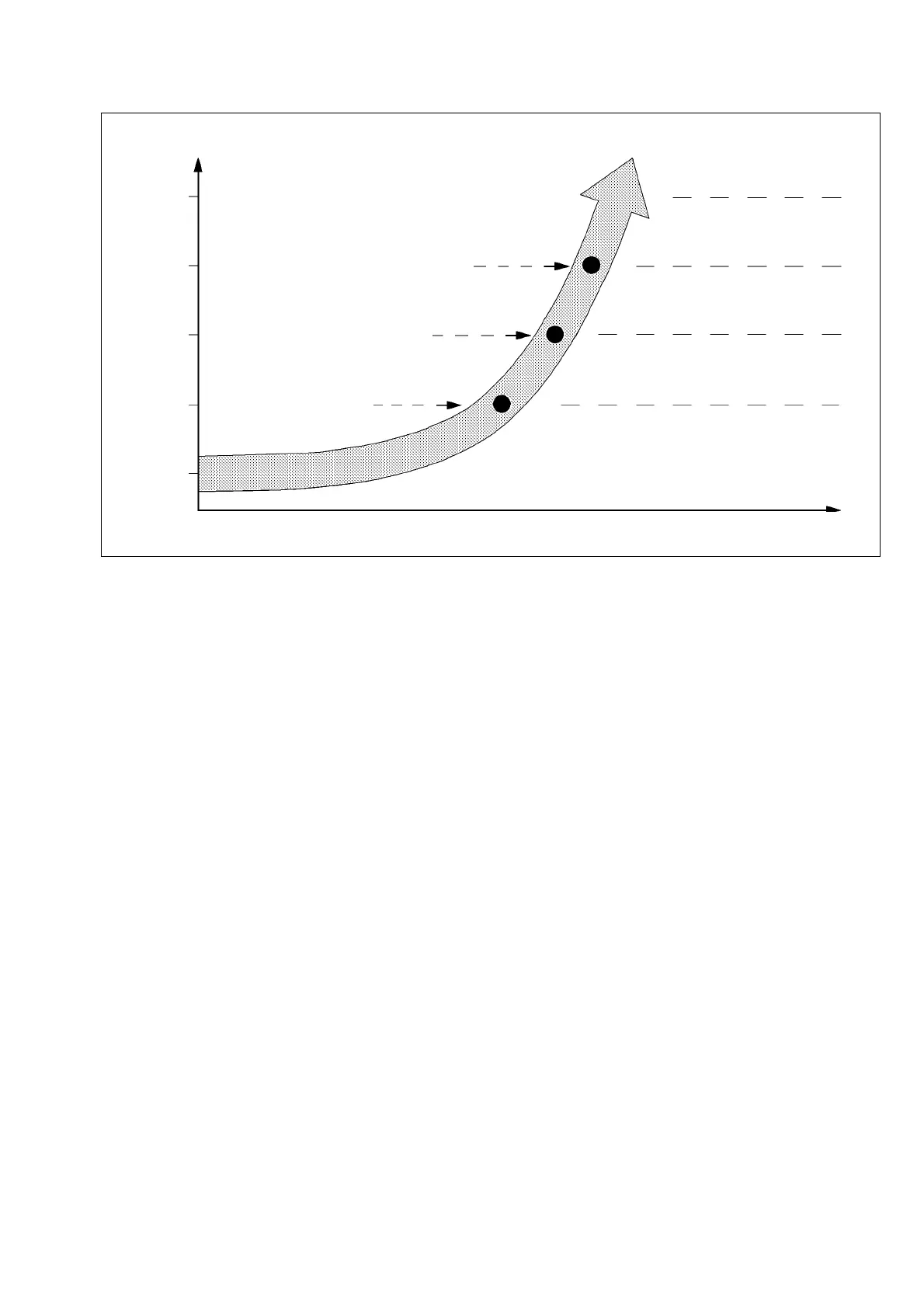

Normal

Report change+ 1 step

Maintenance

activities

+ 2 steps

+ 3 steps

+ 4 steps

Report large increase

Report dangerous increase

Routine

maintenance

(lubrication, etc.)

Inspection,

minor repairs

Plan major

overhaul

(Shutdown)

Effect repairs

Breakdown

Vibration

measurements

To be able to plan ahead and work efficiently, a main-

tenance department needs easily interpreted informa-

tion on all significant changes in machine condition.

Reporting changes in ”steps”, rather than giving the

actual vibration severity figures, is the simplest way of

indicating the extent and urgency of a maintenance

problem.

A one step change (1.6 times increase) is generally

regarded as significant and should be reported. It is a

first warning of deteriorating condition. At this stage,

tightening a few bolts or adjusting a belt may be

sufficient to get rid of the excess vibration. A two

step increase (= one condition zone) should always be

investigated. Three steps up is a fourfold increase, an

alarming change demanding immediate action.

Systematic Vibration Monitoring

Loading...

Loading...