50

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

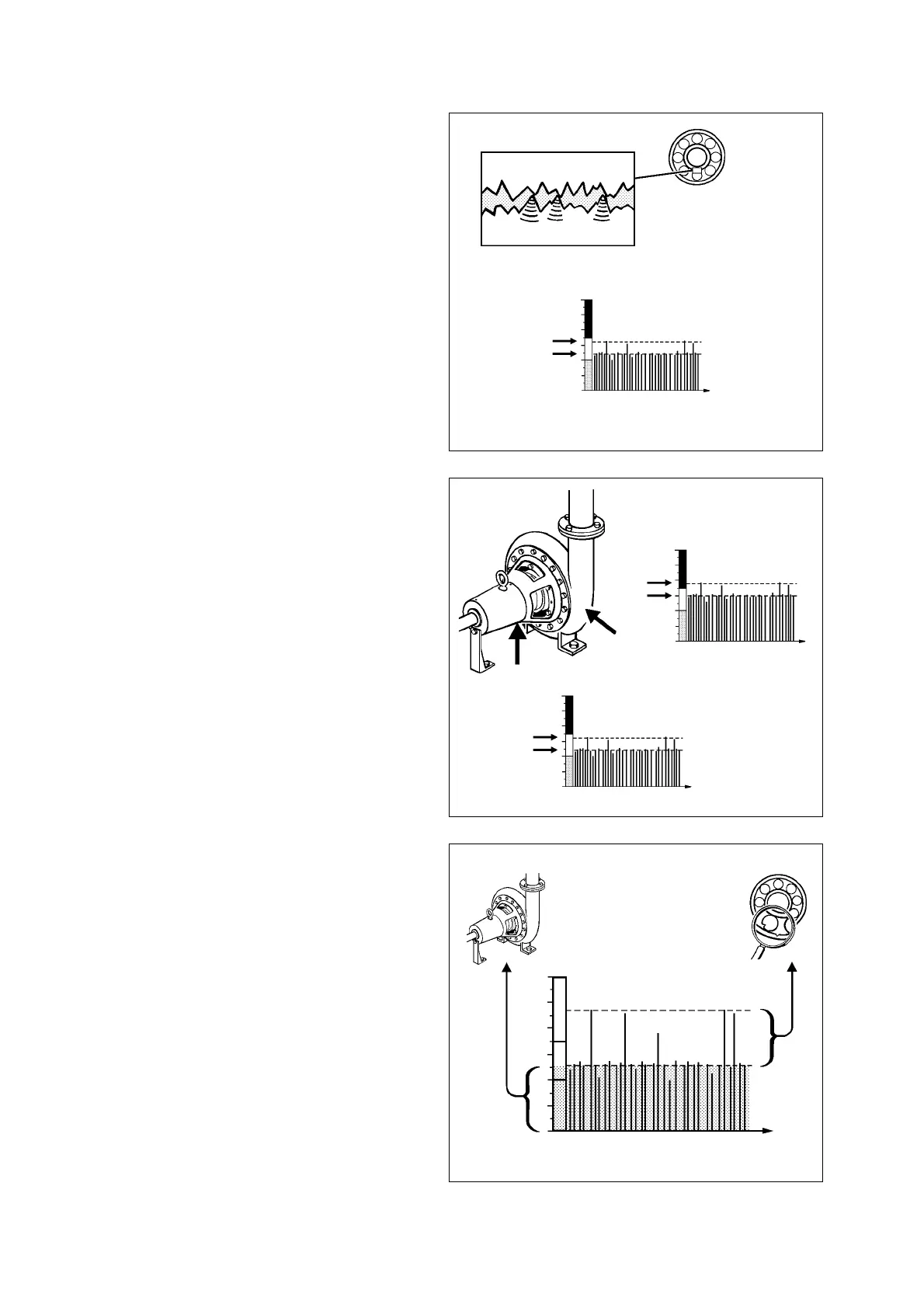

Patterns from Poorly Lubricated Bearings

Fig. 33

Fig. 34

Fig. 35

CODE B and a LR/HR reading with a small delta are

typical for dry running bearings (fig. 33).

If the signal is strongest on the bearing housing, it can

have several causes:

1 insufficient lubricant supply to the bearing (poor

oil flow; old, caked, or cold grease)

2 very low or very high bearing speed (preventing

the build-up of an oil film separation between the

loaded rolling elements and the raceway)

3 installation fault (excessive preload) or out of

round bearing housing

4 misalignment or bent shaft.

If possible, grease the bearing or increase the oil flow.

Measure immediately afterwards, and again a few

hours later. In case 1 (see above), the shock pulse

level should drop and stay low.

In case 2, one can try lubricants of a different viscosity

or use additives to prevent metal to metal contact

between the bearing surfaces.

In cases 3 and 4 (installation faults, unround housings,

and misalignment), the shock pulse level may drop

after lubrication but will soon rise again. Misalign-

ment normally affects the bearings on both sides of

the coupling or at both ends of the shaft.

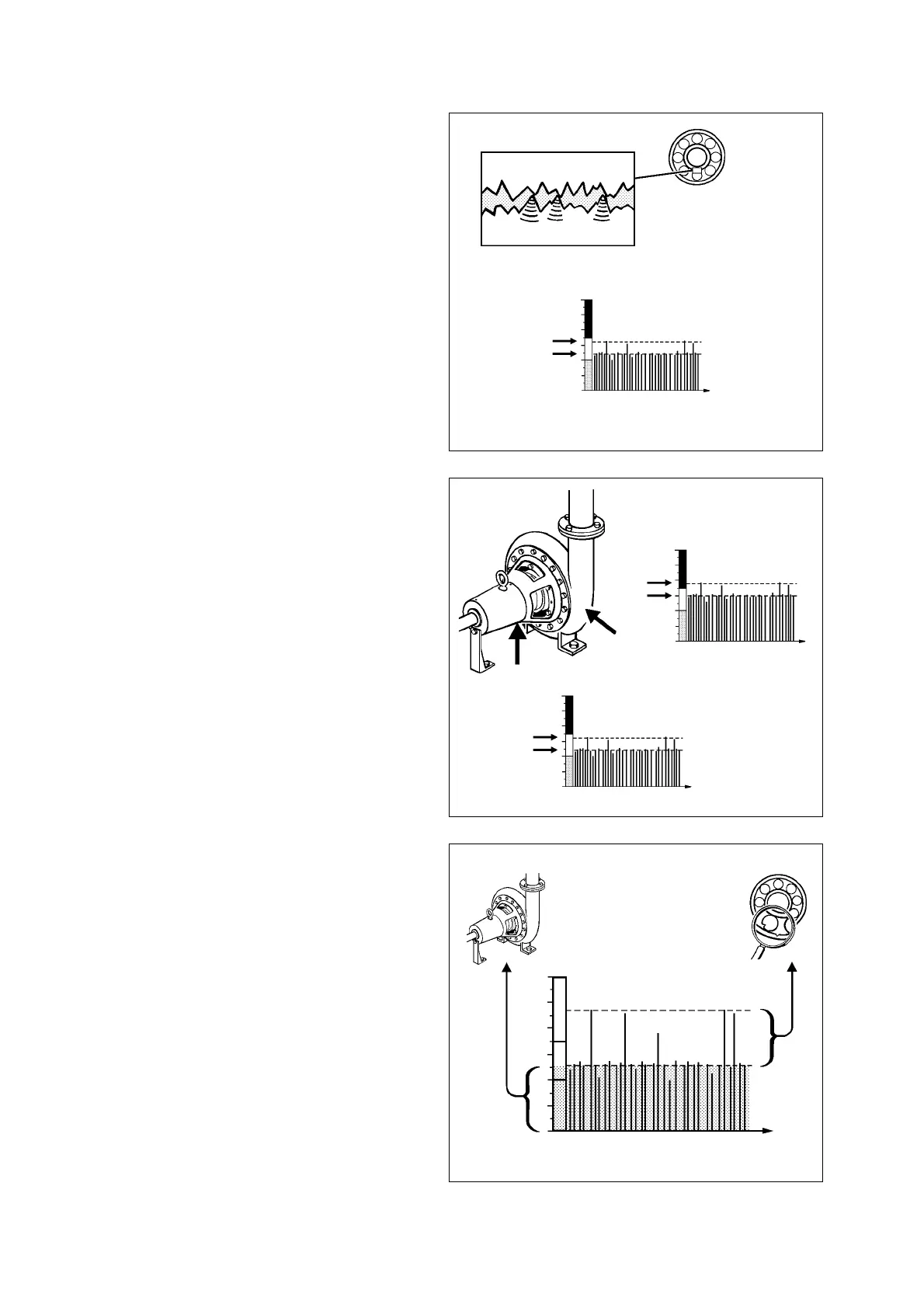

Cavitation and Similar Interference

The shock pulse pattern caused by a cavitating pump

(fig. 34) or by persistent rubbing is identical with that

from a dry running bearing. You have an interference

signal when the shock pulse level is highest outside of

the bearing housing and is not affected by lubricating

the bearing.

If you cannot remove the cause of interference, you

have a ”blind spot”: up to a certain level, the interfer-

ence signal (fig. 35, grey area) will mask the signal

from one or more bearings. However, you may still be

able to detect bearing damage. When the shock level

rises above the interference level, it must be caused

by something else – probably bad bearing condition.

In that case, greasing the bearing should cause the

level to drop, at least temporarily.

A

B

Loading...

Loading...