51

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

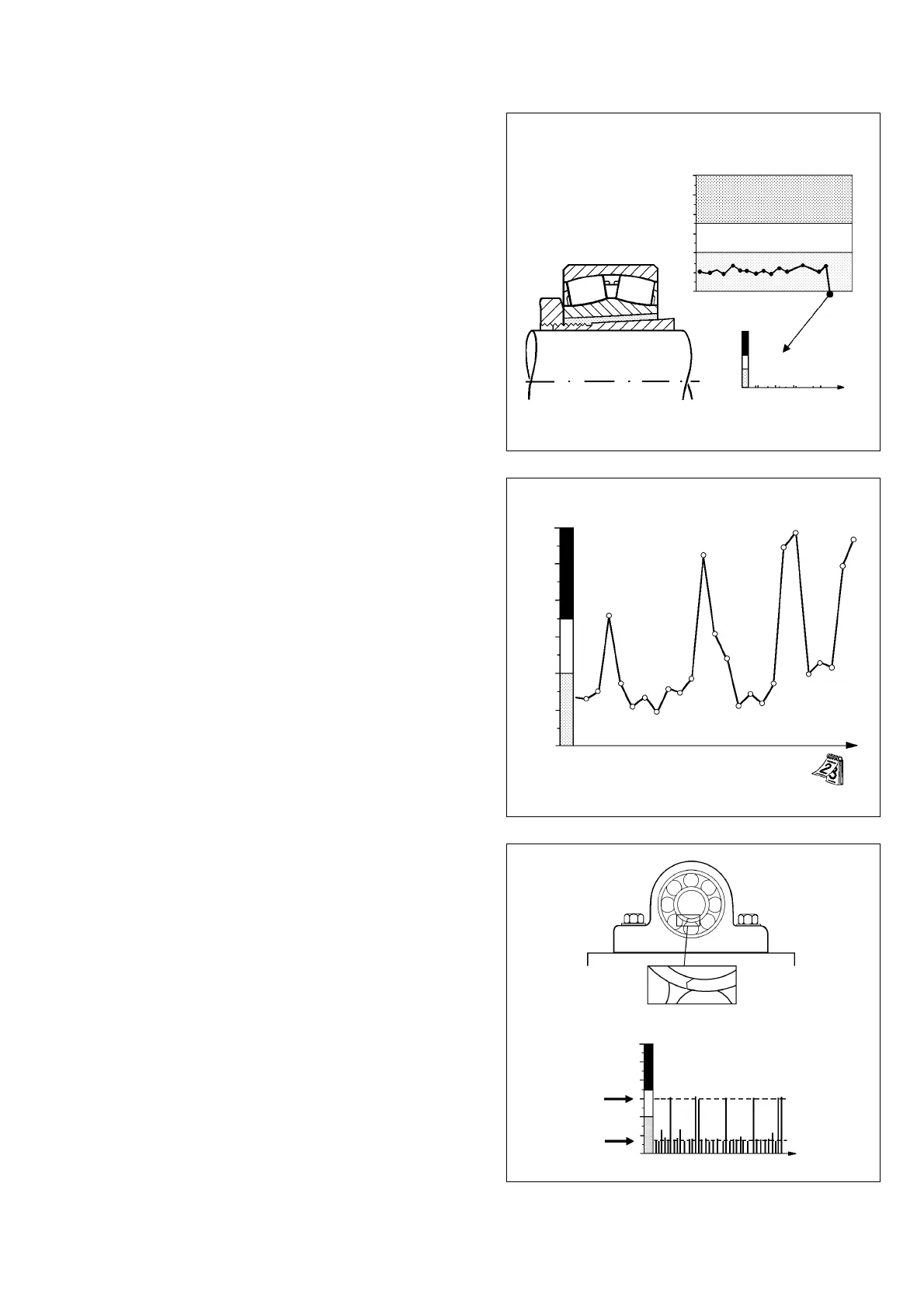

Irregular Measuring Results

Fig. 36

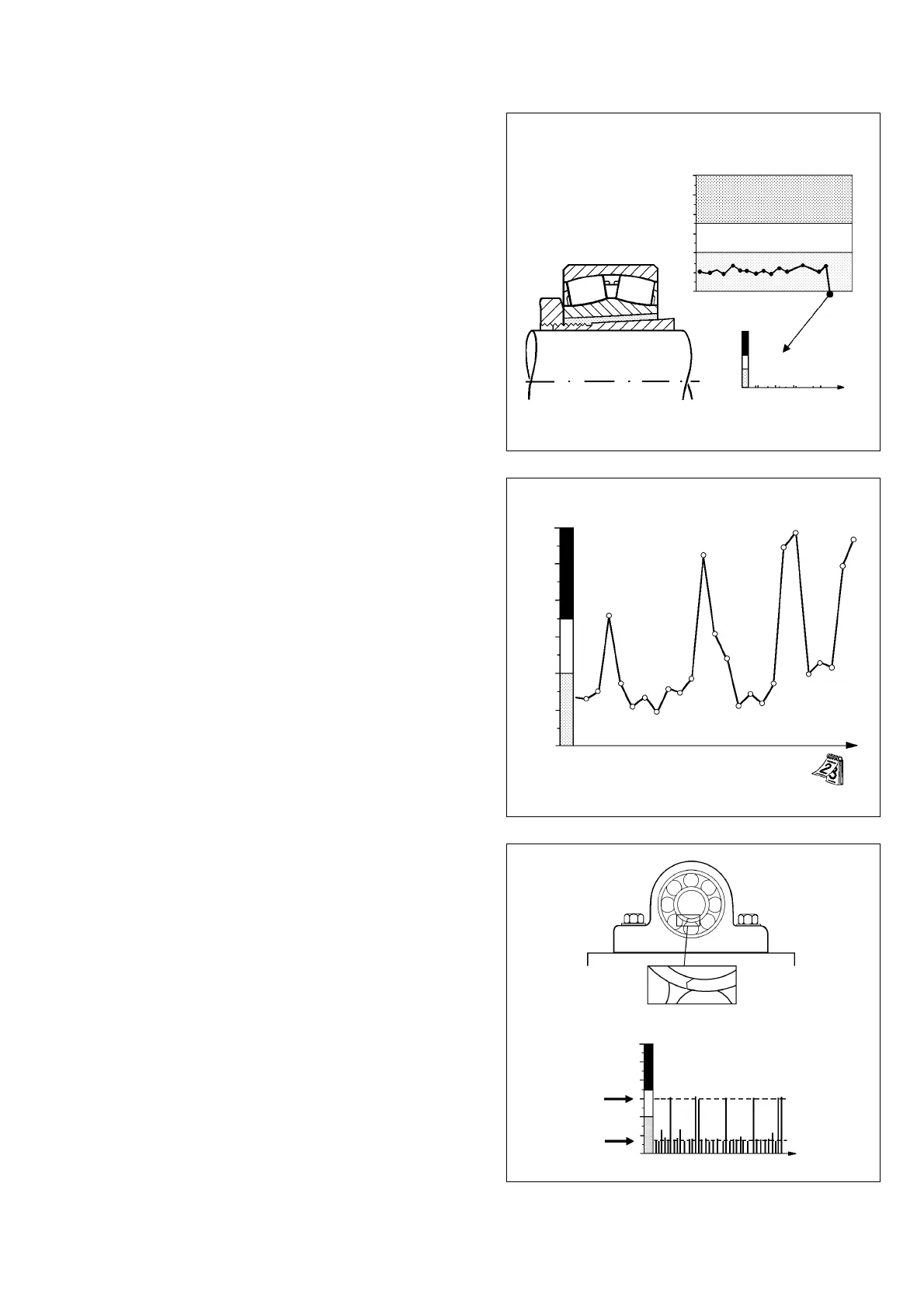

Fig. 37

Fig. 38

Large variations between consecutive readings are a

danger sign. Damaged bearings do not improve with

time, although their shock values may temporarily

drop.

Large Drop in the Readings

If the shock pulse level drops after a sequence of

normal readings, you have either a malfunction of the

instrument, a failure in a transducer installation, or a

serious bearing fault.

Check the instrument by measuring on some other

bearing. In case of an installed transducer, try to get a

reading by tapping on the bearing housing.

If your reading is correct, it is possible that one of the

bearing races is slipping, either on the shaft or in the

housing. In case of a heavily loaded bearing with

previous high readings, suspect cage failure.

Erratic Readings on Roller Bearings

Wide variations in the readings taken at different

times can occur on heavily loaded roller bearings with

surface damage. The high readings are caused by

metal particles breaking off the surfaces and by the

sharp edges of new spallings. When particles and

edges are rolled out, the readings will drop again.

Note that ball bearings and roller bearings have dif-

ferent contact areas. A ball has point contact with the

raceway while a roller has line contact over the whole

width of the raceway. Pitting in the surface of a roller

bearing's raceway will therefore not cause distinctive

shocks as long as there is enough undamaged surface

area to carry the individual roller.

Cracked Inner Ring

A clean crack in the inner ring of a bearing is difficult

to detect, especially at a low r.p.m. You may get low

readings through most of the bearing's rotation, then

one or two peaks while the crack is in the load zone.

Signal strength can differ considerably as the crack

opens or closes depending on bearing temperature.

In time, the surface tends to spall along the crack,

leaving sharp edges and metal particles which cause

high shock values until they are rolled out.

Take your time during measurement, listen with the

ear phone. Watch for other signs of damage, such as

contamination in the lubricant, clogged oil leads, and

increased machine vibration.

Loading...

Loading...