54

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

2

6

3

4

5

1

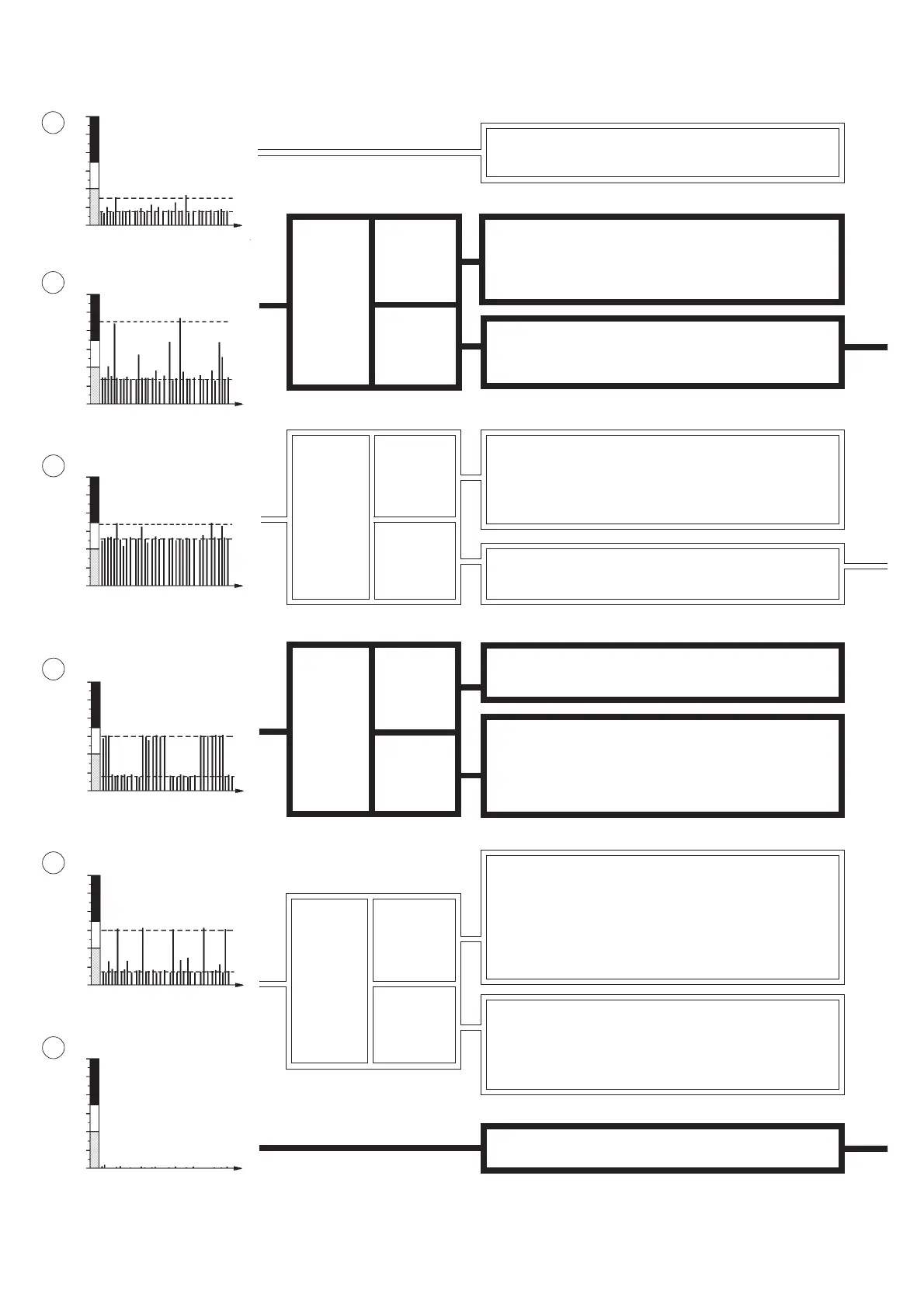

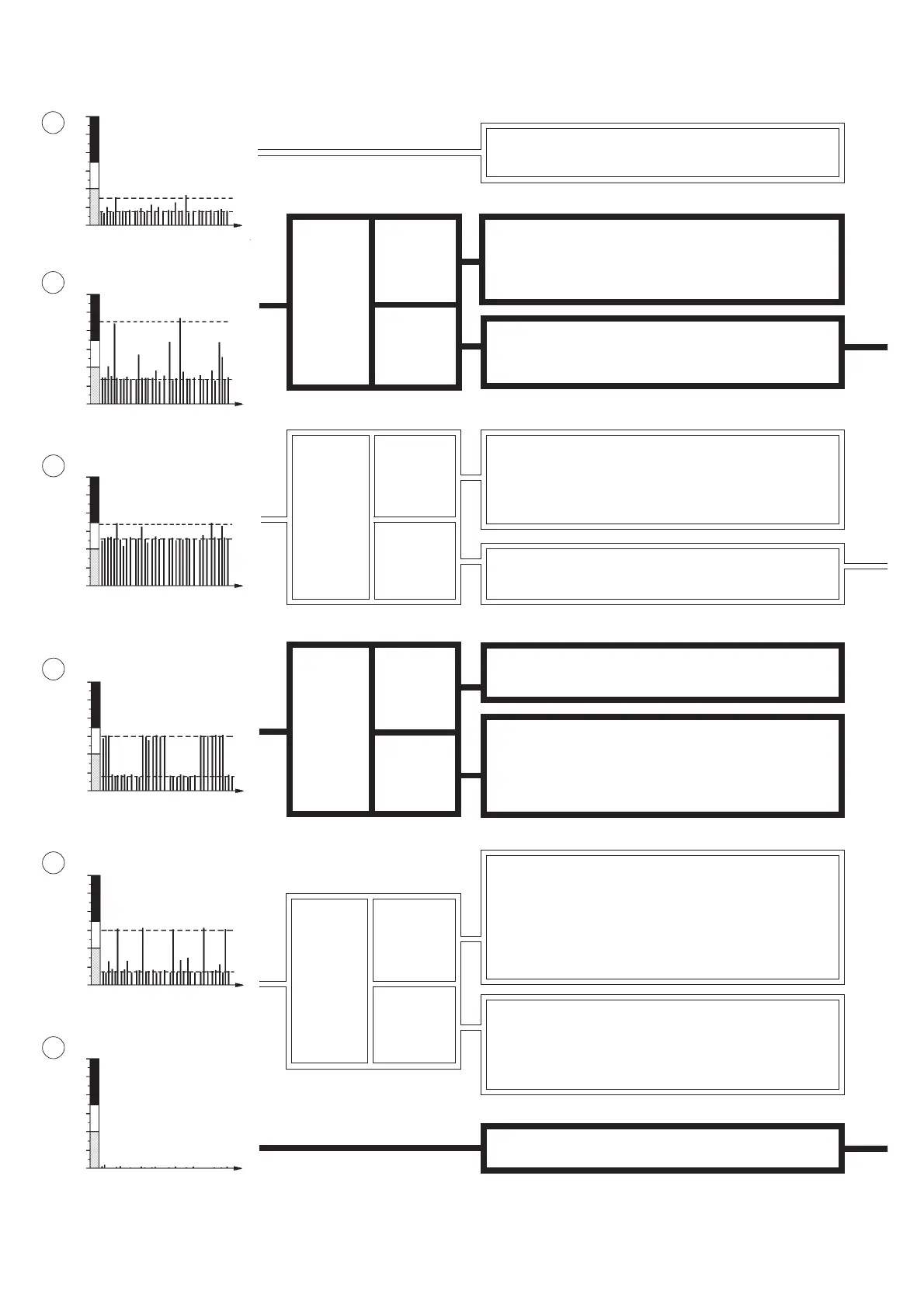

Probable causes:

• The shaft rubs against the bearing housing or the end of the

shaft rubs against the bearing cap

• Gear tooth damage

• Other mechanical rubbing

Newly installed bearing?

Locate the signal source. The reading can be caused by

interference from other defective bearings, cavitation in

pumps or mechanical rubbing. If possible, isolate the source

of disturbance and retest.

Locate the signal source. If possible, isolate the source of

disturbance and retest.

Check the reading of adjecent bearings.

Are the signals from these bearings similar to the tested

bearing?

Locate the signal source. The reading can be caused by cross

talk from other defective bearings or disturbances from other

mechanical shocks. If possible, isolate the source of disturbance

and retest.

On the

bearing

housing

Adjacent to

the bearing

housing

On the

bearing

housing

No or only a very low value can be obtained.

Good bearing condition, installation and lubrication.

Probable causes:

• Load or pressure shocks in the machine's working cycle

causing mechanical shocks in the bearing

• Individual gear tooth damage

• Bearing damage

Where do

you get the

highest

reading?

Where do

you get the

highest

reading?

Where do

you get the

highest

reading?

Where do

you get the

highest

reading?

Adjacent to

the bearing

housing

Adjacent to

the bearing

housing

On the

bearing

housing

Adjacent to

the bearing

housing

On the

bearing

housing

Locate the signal source.

Probable causes:

• Load or pressure shocks from equipment installed on the

machine frame

• Other mechanical shocks from the machine's working cycle

If possible, isolate the source of disturbance and retest.

Evaluation Flow Chart

Loading...

Loading...