6

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 1996-9. 71411.B

SPM Instrument AB • Box 4 • S-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.se

Shock Pulse Transducers and Accessories

A basic requirement for condition monitoring is ac-

cess to suitable measuring points. Over the last 20

years, SPM has developed a large range of accesso-

ries and installation components which enable the

customer to reach bearings in almost any application.

The A2010 offers three alternative ways of measuring

shock pulses:

• a hand-held probe is pressed against the bearing

housing.

• an adapter is permanently installed on the

bearing housing. Readings are taken by attaching

a transducer with quick connector to the adapter.

• a shock pulse transducer is permanently installed

on the bearing housing and via coaxial cable

connected to a measuring terminal. Readings are

taken by connecting the A2010 to the terminal.

The hand-held probe is used for spot checks, for

locating the best measuring points for systematic moni-

toring, and for tracing other shock pulse sources on

the machine, for example cavitation or rubbing and

scraping machine parts.

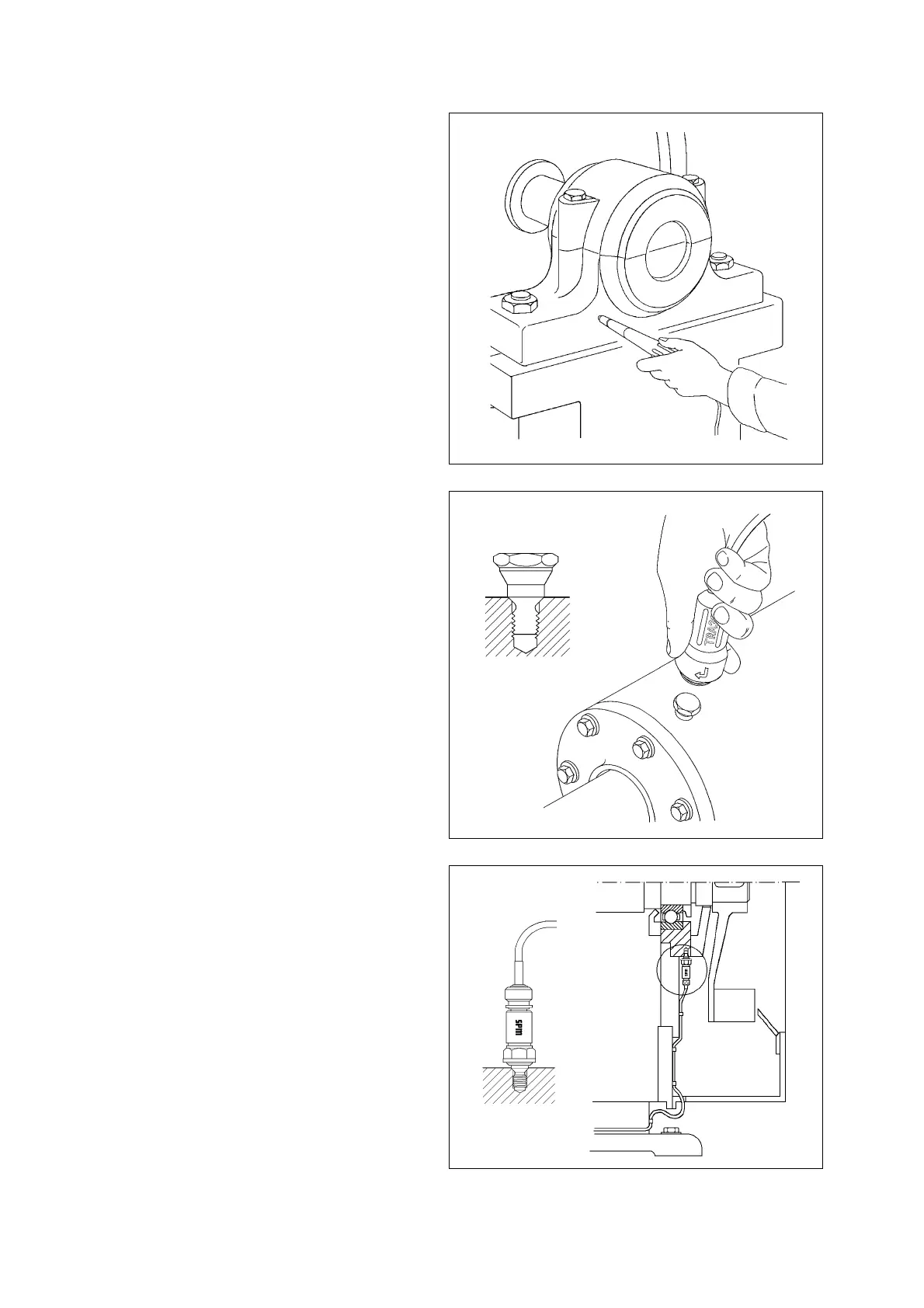

For systematic shock pulse monitoring on a larger

number of measuring points, SPM recommends the

use of shock pulse adapters. Adapters are solid steel

bolts, installed in threaded, countersunk mounting

holes. The transducer is connected with a quick twist,

leaving the operators hands free for the instrument.

Adapters make clearly defined measuring points and

permit more accurate readings with less spread.

An alternative is the SPM transducer TRA-20 which

snaps on to a measuring stud. Studs are installed in

threded holes. Studs as well as adapters are available

in glue-on versions for thin-walled bearing houses.

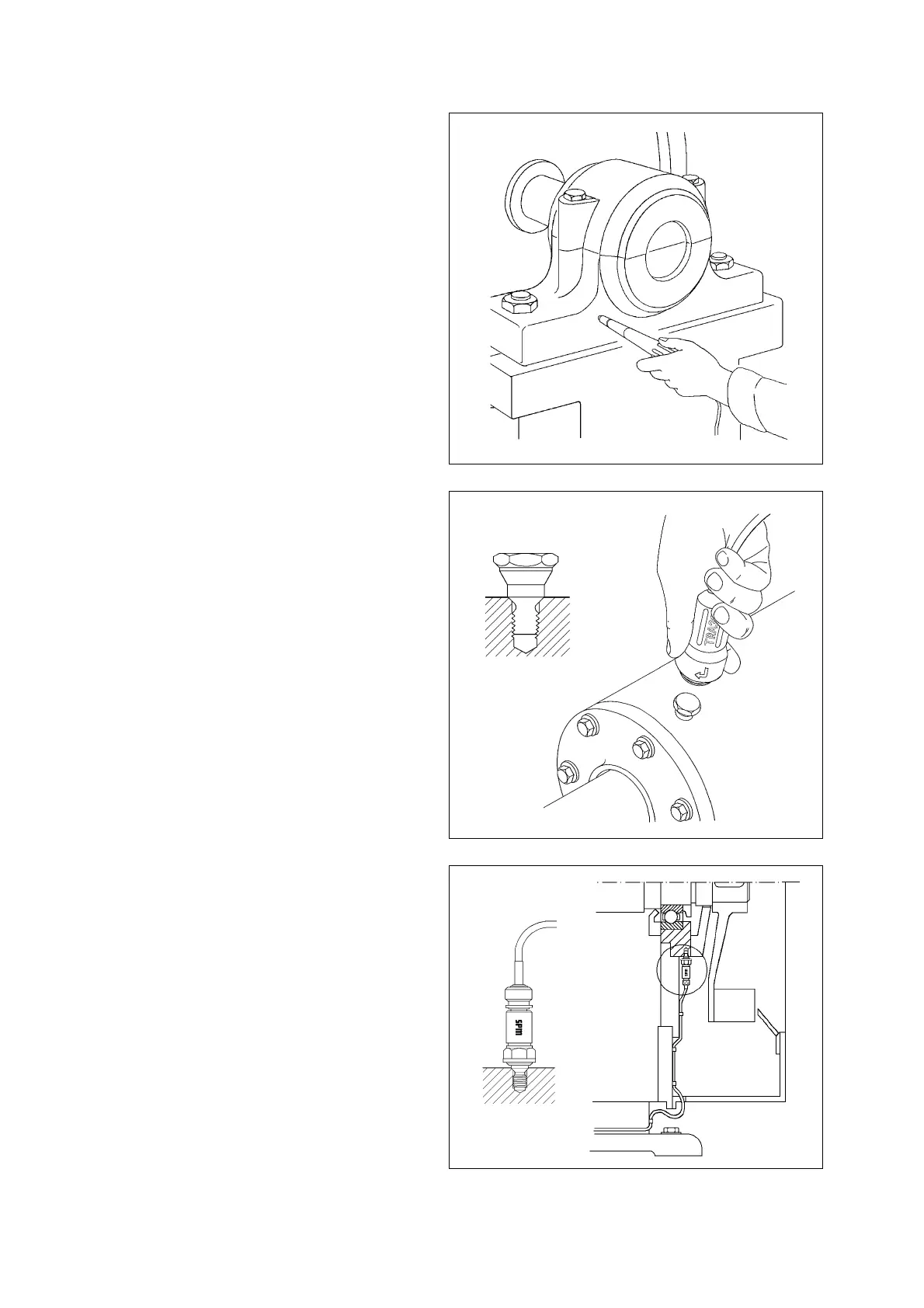

Permanently installed transducers (fig. 5) are primarily

used for bearings which cannot be reached in any

other way during normal machine operation. Trans-

ducer matching units allow cable lengths of up to 100

m between bearing and measuring terminal.

Fig. 3

Adapter

Fig. 4

Fig. 5

Transducer

Loading...

Loading...