95 B58FZS 0000000078 EN 002

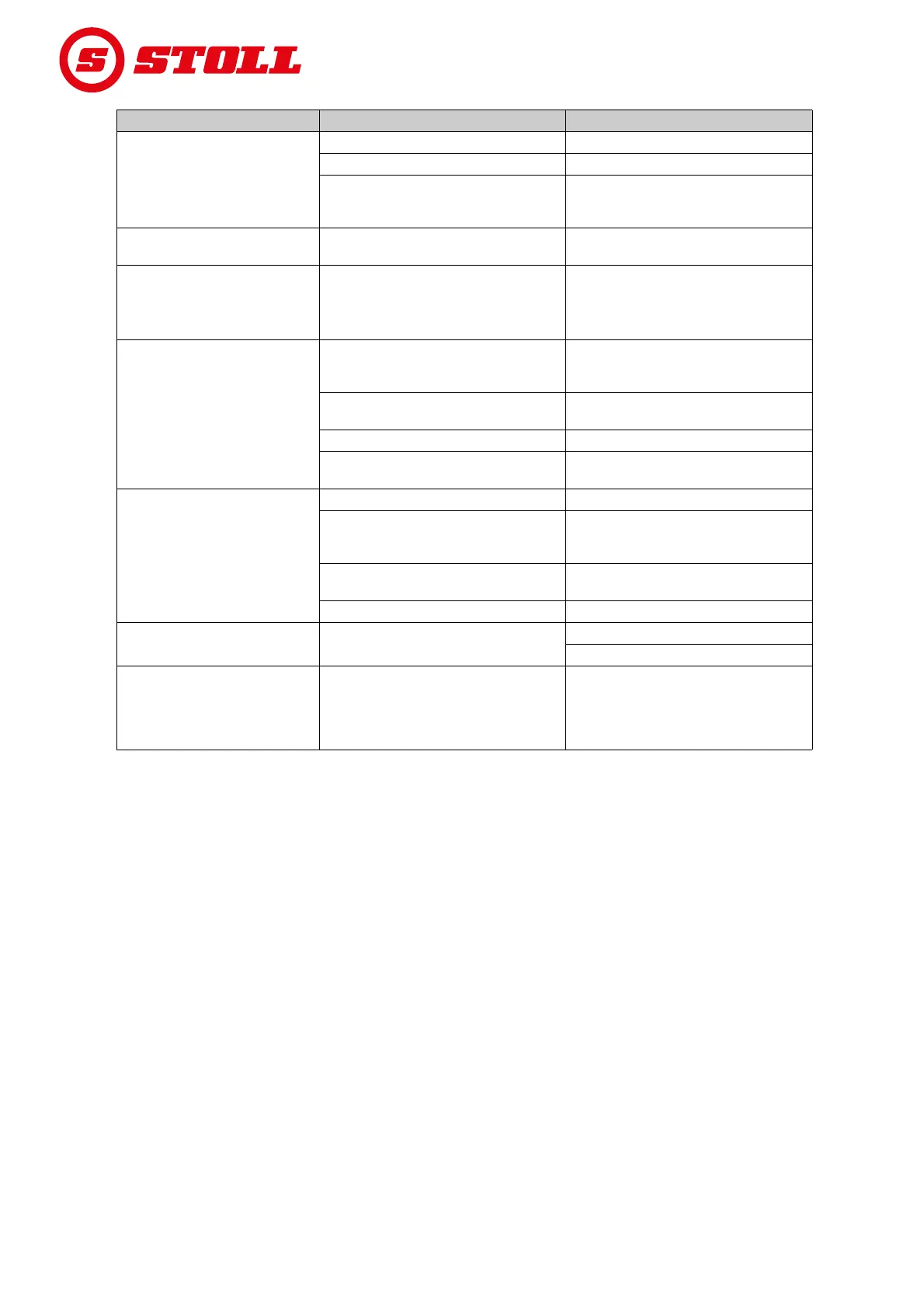

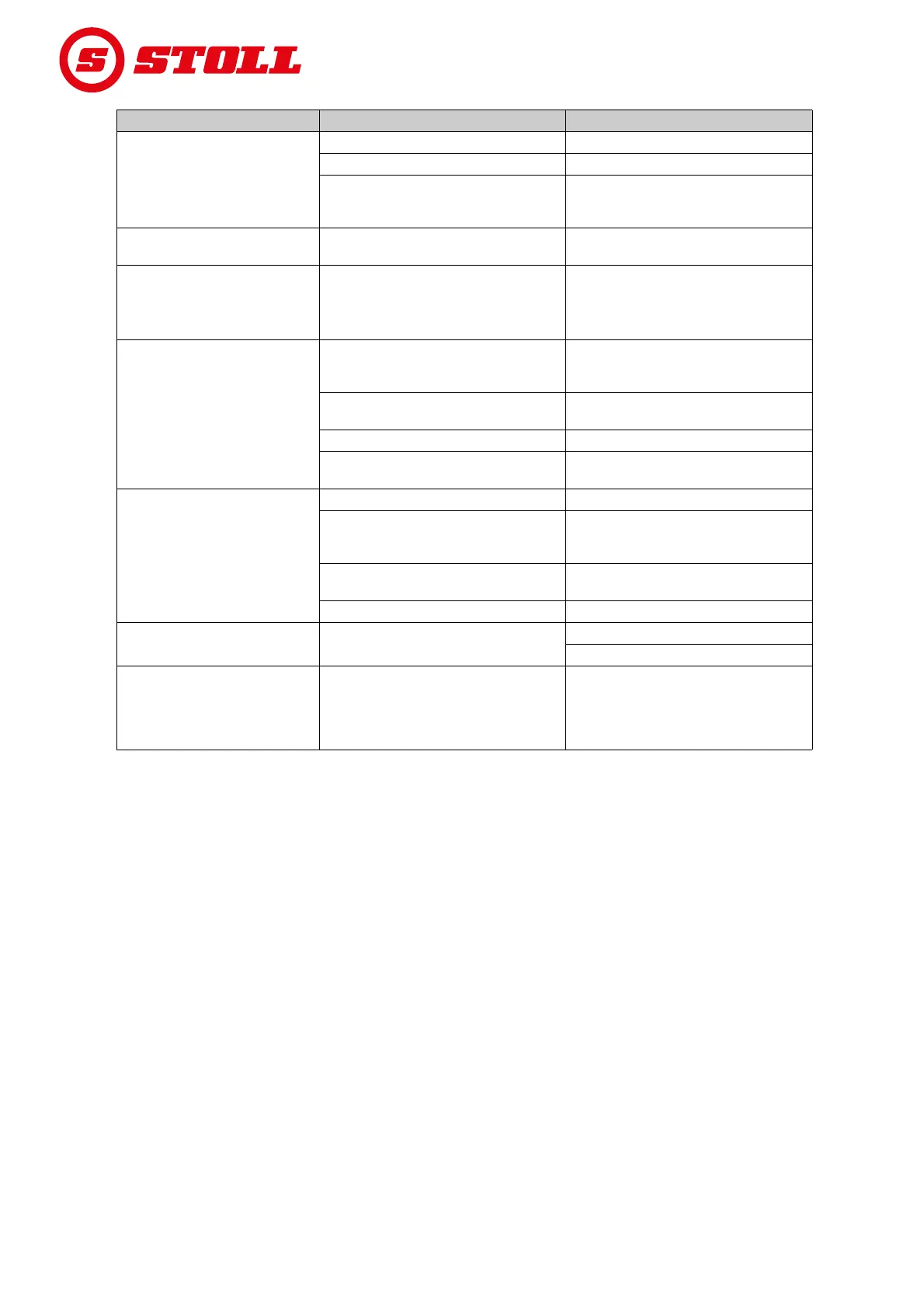

TROUBLESHOOTING

Front loader, implement and

implement with hydraulic function

is blocked during lifting or lowering

movement.

Coupling not completely closed. Check the hydraulic coupling.

The coupling is defective. Replace the defective coupling halves.

Hydro-Fix, multi-coupler and Implement-

Fix not fully closed.

Check the locking lever for deformation.

Check the couplings for firm seating, fasten

if necessary.

The front loader rocks when

lowering the load.

Lowering speed too high. Reduce the lowering speed.

Unstable implement on FS rapid

emptying front loaders (implement

tilts away backwards).

Rapid emptying activated without dumping.

This causes a vacuum in the hydraulic

system.

Only activate the rapid emptying during the

dumping process.

Increase the engine speed in order to

deliver enough oil.

The implement cylinder are

extended, but are not retracted

again.

Piston seal in the implement cylinder is

defective, so that the surface of the piston

and the ring are stuck together.

Check each cylinder separately for leaks

and if necessary replace any defective

cylinders.

Seat valve does not return to starting

position after turning on the rapid emptying.

Remove seat valve and check for debris, if

necessary, replace.

Insufficient oil flow. Check the tractor hydraulics.

The double pressure relief valve of the front

loader control block does not close.

Clean the double pressure relief valve and

replace if necessary.

Leaks on the hydraulic block and

system.

Loose bolted connections. Tighten the screw again.

Leak between the magnet and valve. Unscrew the knurled nut, remove the

magnet, tighten the magnetic core again

with an open-end spanner.

Leak between the valve flanges. Tighten the screws again or renew the

gasket rings.

Defective gaskets. Replace the gasket rings such as Walform.

The front loader is raised when

scooping from a lowered position.

Oil shortage on the piston rod side of the

lifting arm cylinder.

Increase the engine speed when lowering.

Lower without float position.

The front loader is raised when

scooping from a lowered position,

and when subsequently dumping,

the front loader is lowered very

fast.

Oil shortage on the piston crown side of the

lifting arm cylinder.

After the previous error, only actuate the

lifting function until the front loader is raised

and the implement can be carried in a

parallel position.

Description of the fault Cause Rectifying the fault

Loading...

Loading...