TIMING BELT ASSEMBLY

MECHANICAL

B: INSTALLATION

ER ASSEMBLY AND BELT IDLER

1)

Preparation for installation

of

automatic belt ten-

sion adjuster assembly:

CAUTION:

Always use a vertical type pressing tool to

move the adjuster rod down.

Do

not use a lateral type vise.

Push the adjuster rod vertically.

Be sure to slowly move the adjuster rod down

applying a pressure of

294

N

(30 kgf,

66

Ib).

Press-in the push adjuster rod gradually tak-

ing more than three minutes.

Do

not allow press pressure to exceed

9,807

N

(1,000

kgf,

2,205

Ib).

Press the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing

so

may damage the

cylinder.

Do

not release the press pressure until stop-

per pin is completely inserted.

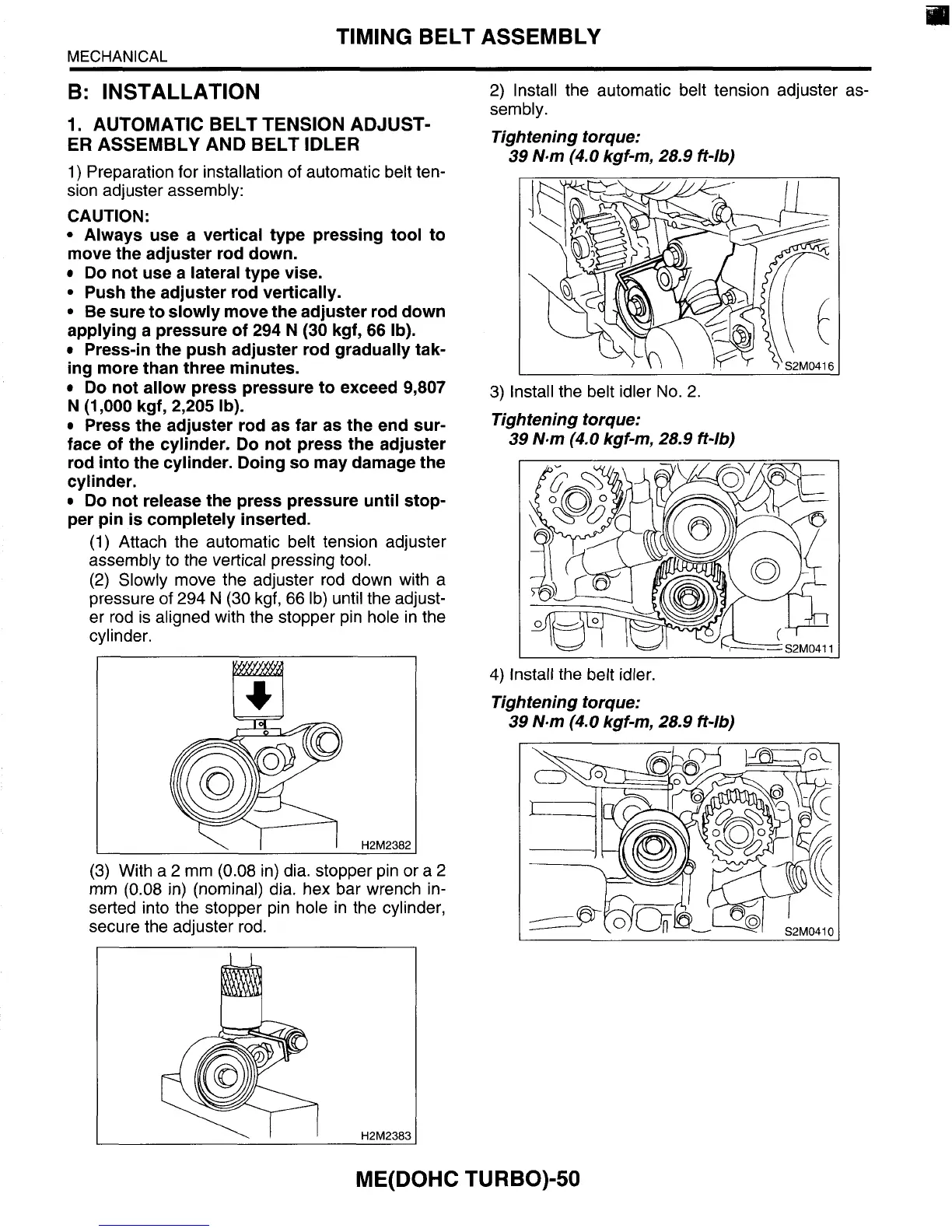

(1)

Attach the automatic belt tension adjuster

assembly to the vertical pressing tool.

(2)

Slowly move the adjuster rod down with a

pressure

of

294

N

(30

kgf,

66

Ib) until the adjust-

er rod is aligned with the stopper pin hole in the

cy1 inde r.

1.

AUTOMATIC BELT TENSION ADJUST-

\I

1

H2M23821

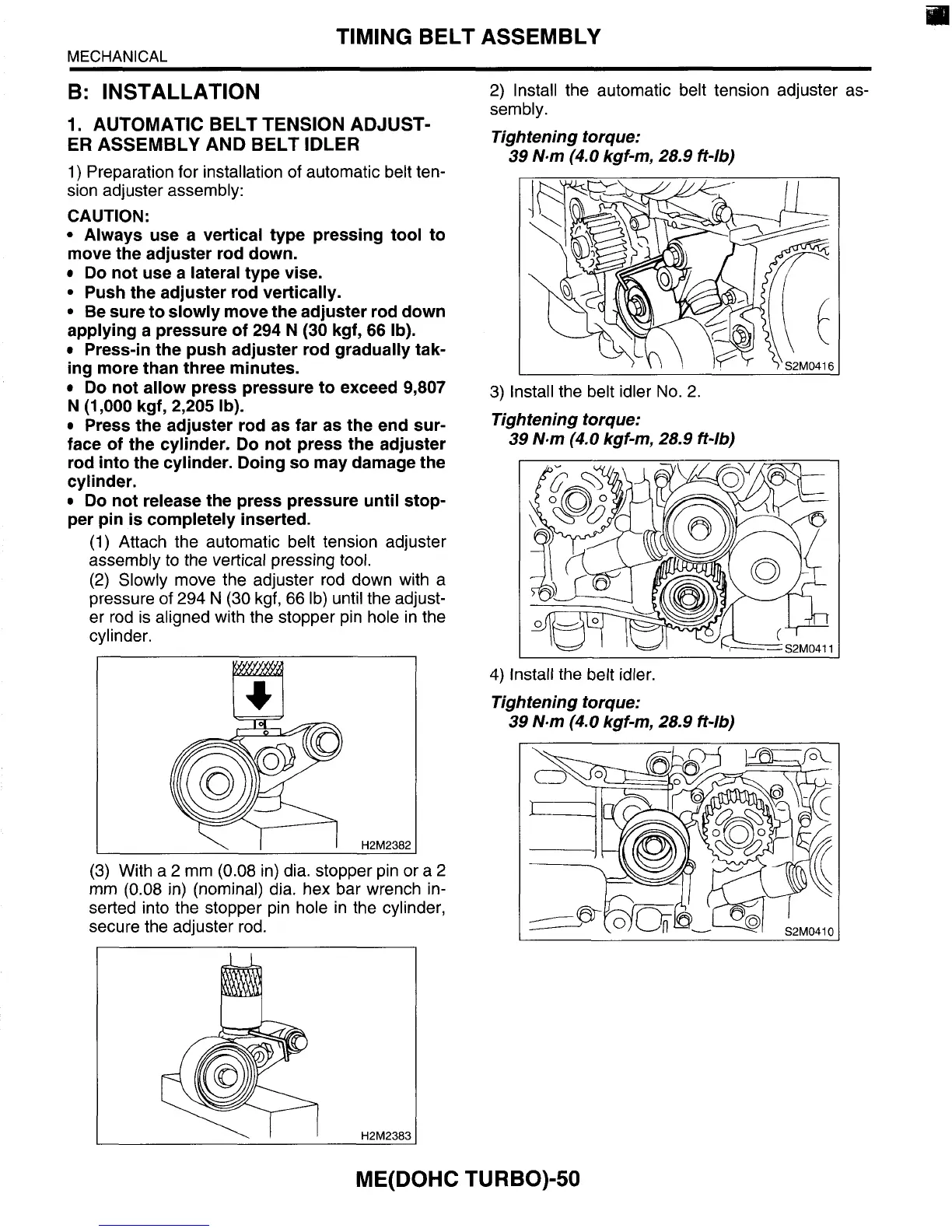

(3)

With a

2

mm

(0.08

in) dia. stopper pin or a

2

mm

(0.08

in) (nominal) dia. hex bar wrench in-

serted into the stopper pin hole in the cylinder,

secure the adjuster rod.

2)

Install the automatic belt tension adjuster as-

sembly.

Tightening torque:

39 N-m

(4.0

kgf-m,

28.9

ft-lb)

3)

Install the belt idler No.

2.

Tightening torque:

39 N.m

(4.0

kgf-m, 28.9 ff-lb)

4)

Install the belt idler.

Tightening torque:

39 N.m

(4.0

kgf-m, 28.9 ft-lb)

ME(D0HC TURBO)-50

Loading...

Loading...