171

1

2

3

4401

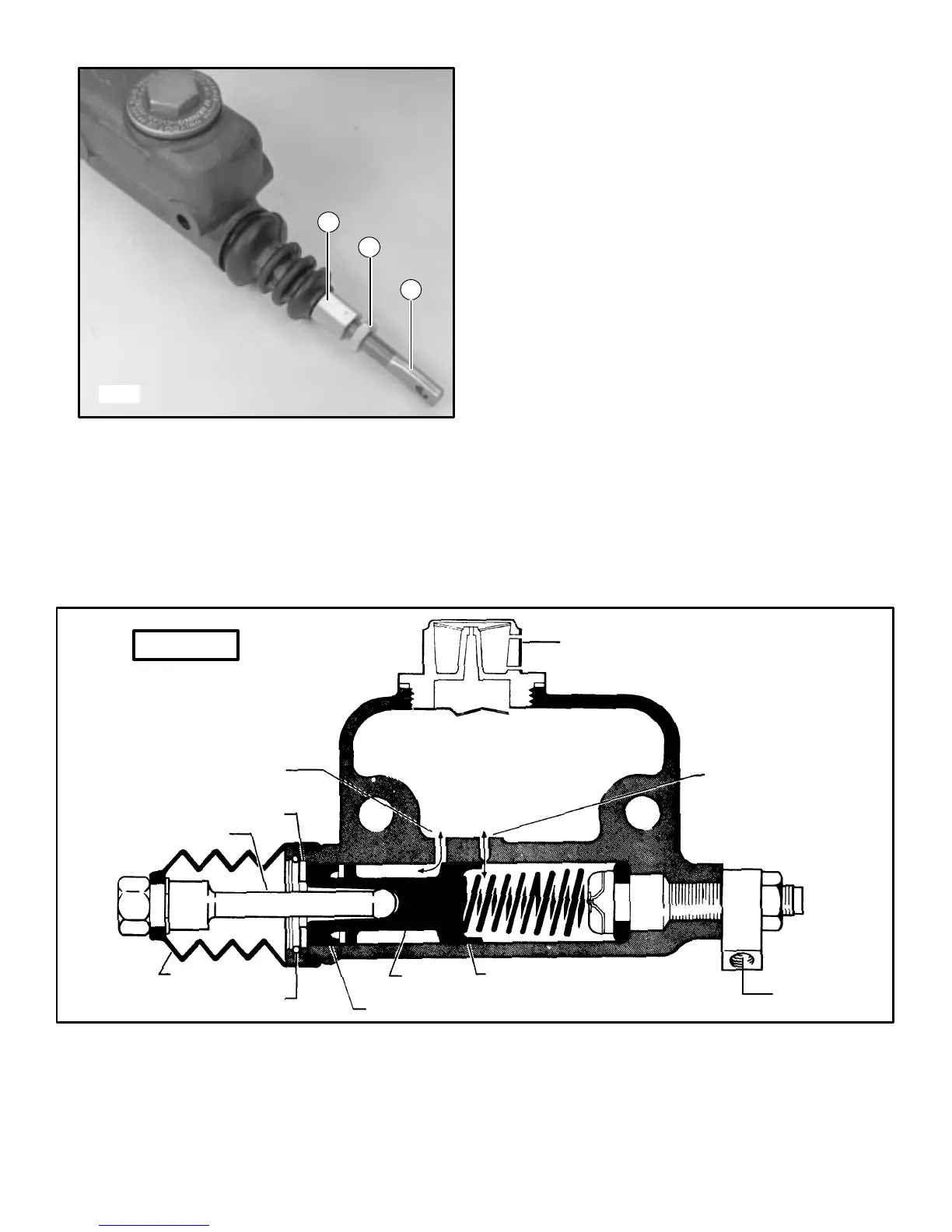

FIGURE 12

1. Brake Rod

2. Locknut

3. Push Rod

Rebuild Procedure For Master Cylinder

If cylinder is to be rebuilt, remove from vehicle and pro-

ceed as follows:

1. Remove filler cup and gasket and pour fluid from res-

ervoir. (Do not reuse fluid).

2. Remove boot from cylinder.

3. Remove lock ring, washer, pistons, primary cup,

spring, valve and valve seat from cylinder.

4. Clean cylinder and filler cup thoroughly in alcohol.

(Do not use gasoline or kerosene).

5. Inspect walls of master cylinder barrel for rust or

score marks; if necessary recondition by honing.

Brake cylinder hones are available from automotive

supply distributors. Hone only enough to clean up

the wall. Clean cylinder again with alcohol, dry with

compressed air.

6. Reassemble in reverse order. Dip all internal parts in

brake fluid prior to assembly.

7. Install the master cylinder in the vehicle, fill with fluid

and bleed the brake system. Check for leaks prior to

returning vehicle to service.

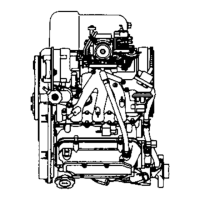

BRAKE FLUID RESERVOIR

COMPENSATING

PORT

VENTED CAP

FILLER PORT

STOP WASHER

PUSH ROD

LOCK RING

RUBBER BOOT

SECONDARY CUP

PISTON PRIMARY CUP

TO

WHEEL

CYLINDER

FIGURE 13

NOTICE

• Severe pitting, scoring,

and/or rust requires replace-

ment with a new or rebuilt

master cylinder.

REBUILD PROCEDURE FOR 1” WHEEL CYLINDERS

Disconnect brake line and brake shoes and remove the

wheel cylinder. Remove the boot from each end of the

cylinder, push the pistons, rubber cups and spring from

the cylinder. Wash cylinder in alcohol. Examine walls for

Loading...

Loading...