176

WARNING

!

• When it is necessary to raise the vehicle for any

repair or service, use jackstands to provide ade-

quate support. DO NOT rely on hydraulic or

mechanical jacks.

NOTICE

• The complete steering gear must be removed to

adjust fork pivot bearings. Refer to the steering gear

overhaul section for proper parts positioning,

assembly sequence and torque specifications dur-

ing assembly.

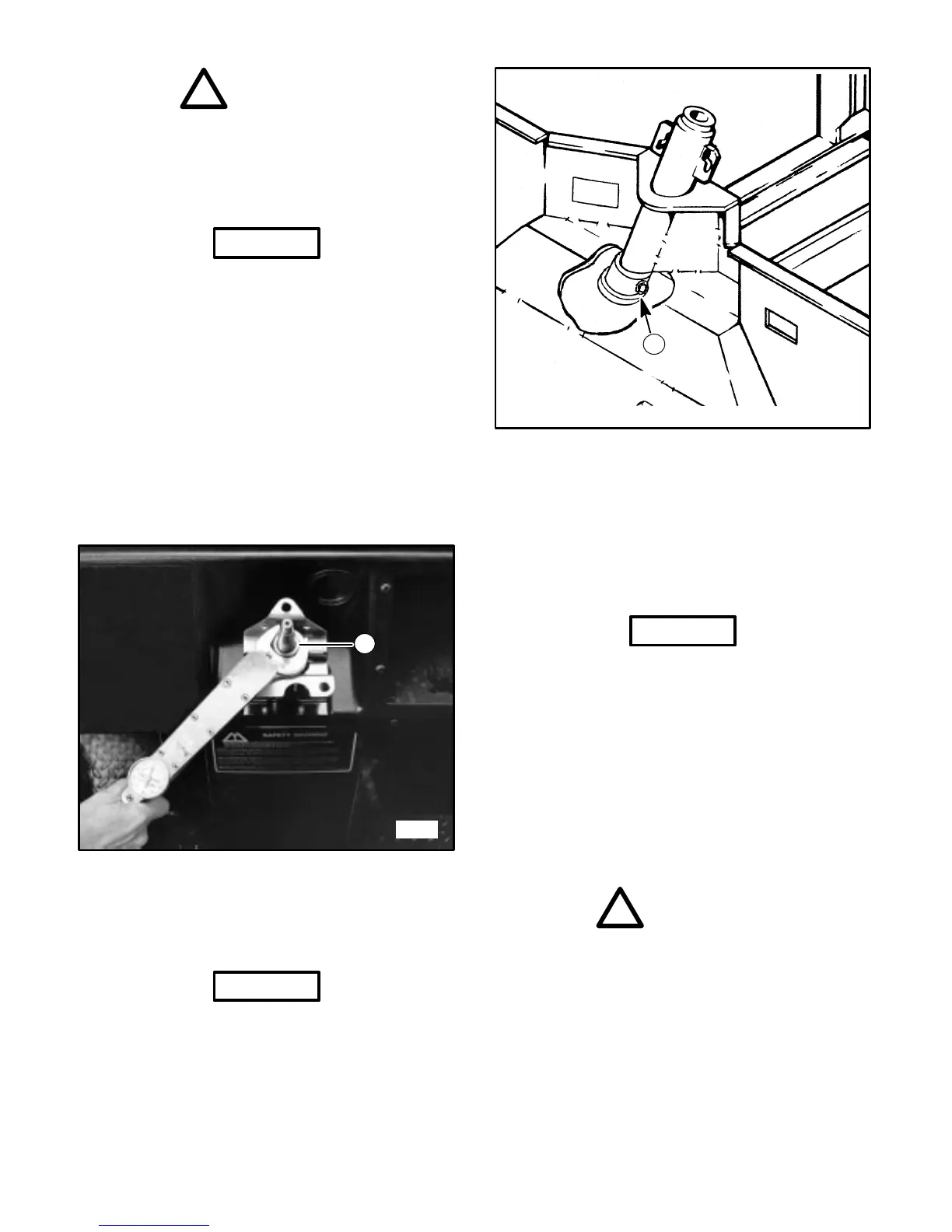

2. Tighten the jam nut to 15 ft.–lbs. (20 N⋅m) torque.

Hold this nut to keep it from turning and tighten the

locking nut to 91 ft.–lbs. (120 N⋅m) minimum, 109 ft.–

lbs. maximum torque. Refer to Figure 20.

1

4390

FIGURE 20

1. Jam Nut

NOTICE

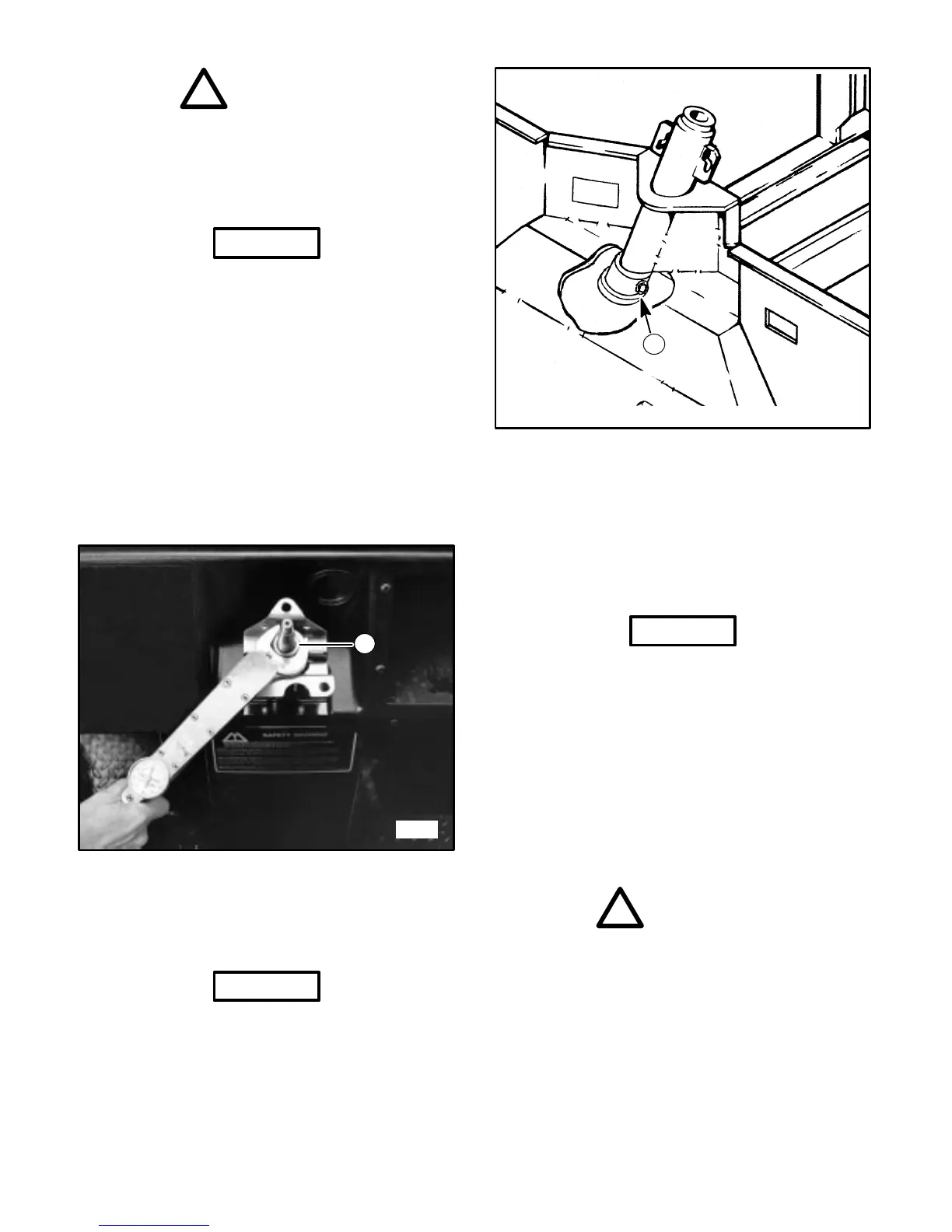

• The adjustments shown will depress the wave wash-

ers and provide the proper preload on the bearings.

The fork must turn freely side to side.

3. Lubricate fork tube lubrication fitting. See Figure 21

for location of fork tube fitting.

1

FIGURE 21

1. Fork Tube Lubrication Fitting

FRONT WHEEL BEARINGS

NOTICE

• The front wheel is mounted on taper roller bearings

that must be checked periodically to insure proper

operation and durability.

• The bearings should be repacked yearly with a lith-

ium based lubricant.

1. Raise the front of the vehicle off the floor.

WARNING

!

• When it is necessary to raise the vehicle for any

repair or service, use jackstands to provide ade-

quate support. DO NOT rely on hydraulic or

mechanical jacks for support.

2. Remove the front wheel and hub assembly by

removing the axle nut, lockwasher and by rotating

the axle lock to allow the axle assembly to slide from

the fork sidearm assembly. Refer to Figure 22 on

page 25.

Loading...

Loading...