28

ALTERNATOR BELT INSPECTION

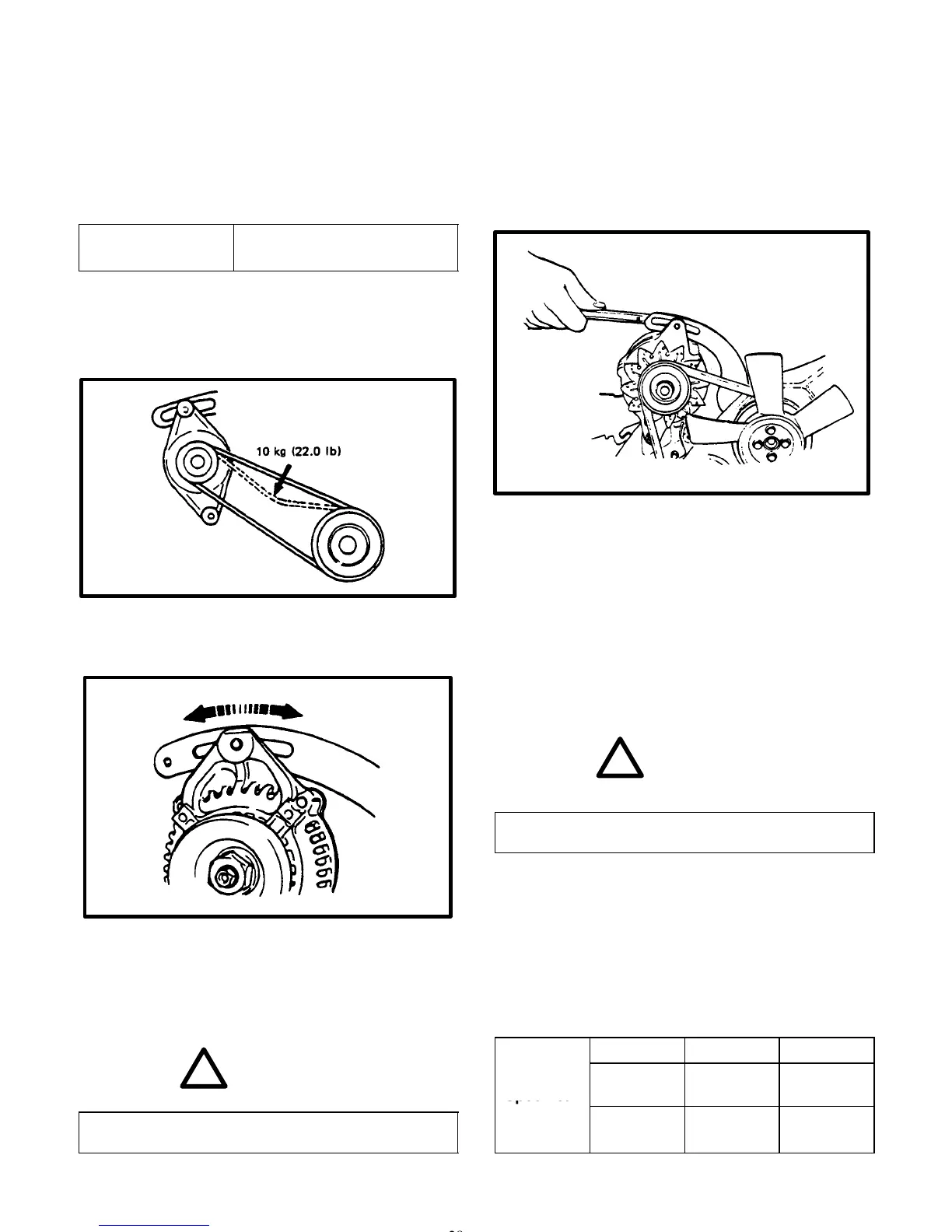

1) Disconnect negative battery lead at battery.

2) Inspect belts for cracks, cuts, deformation, wear and

cleanliness. Check belt for tension. The belt is in proper

tension if it deflects 11 to 14mm (0.43–0.55in.) under

thumb pressure (about 10 kg or 22 lbs.).

Belt tension

specification

11–14 mm (0.43–0.55 in.)

as deflection

NOTE:

When replacing belt with a new one, adjust belt ten-

sion to 10–12mm (0.40–0.47 in.)

3) If the belt is too tight or too loose, adjust it to

specification by adjusting alternator position.

4) Tighten alternator adjusting bolt and pivot bolt.

5) Connect negative battery lead to battery.

WARNING

!

All inspections and adjustments noted above are

to be performed with ENGINE NOT RUNNING.

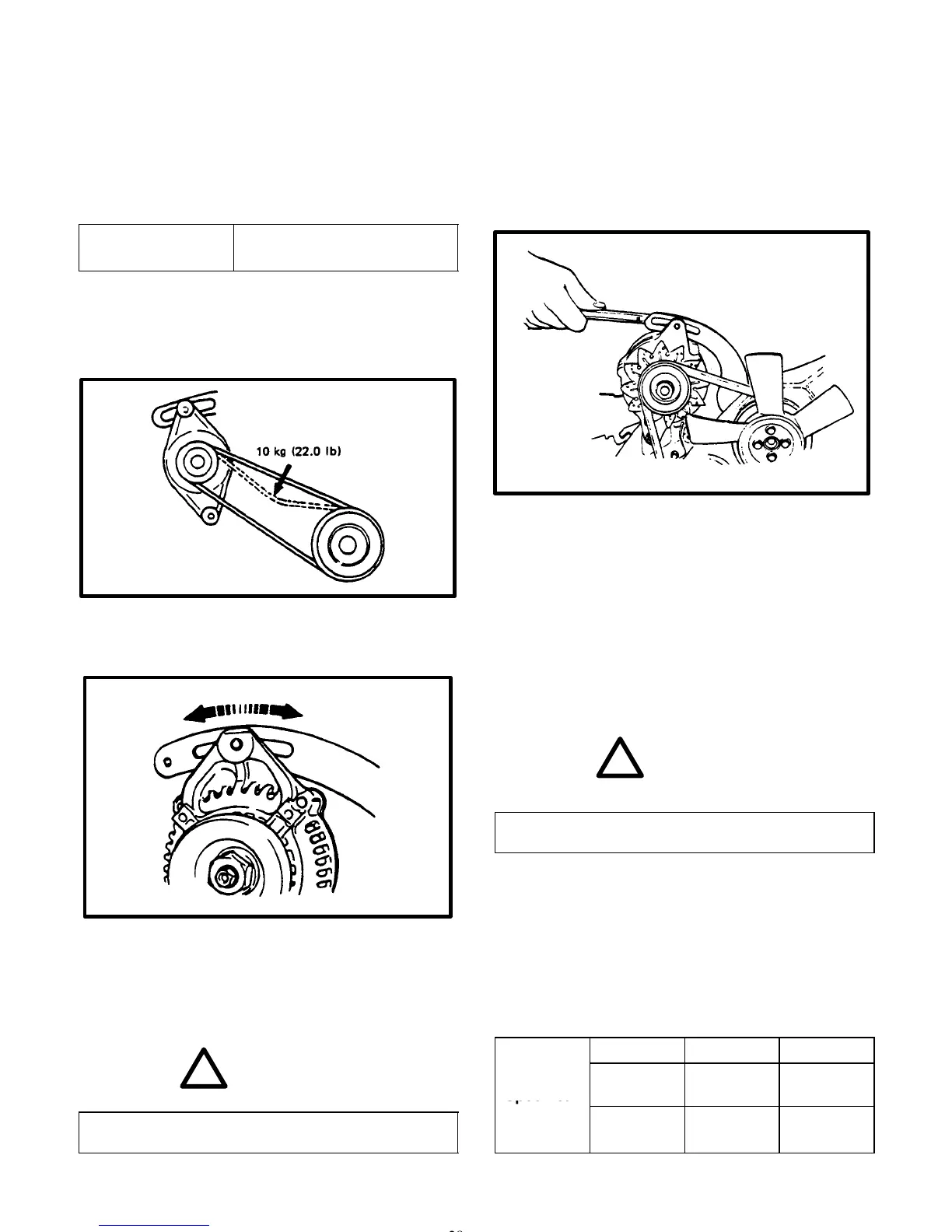

Replacement and adjustment

1) Disconnect negative battery lead at battery.

2) Loosen alternator adjusting bolt and pivot bolts, move

alternator inward.

3) Replace belt.

4) Move Alternator outward and adjust belt to specified

tension.

5) Tighten alternator adjusting bolt and pivot bolts

6) Connect negative battery lead to battery.

WARNING

!

All adjustments noted above are to be performed

with ENGINE NOT RUNNING.

VALVE LASH INSPECTION

1) Remove engine valve cover.

2) Inspect intake and exhaust valve lash and adjust as

necessary.

Cold Hot

Valve Lash

Specifica-

Intake

tions

0.10mm 0.12mm

x

aus

(.0039 in.) (.0047 in.)

Loading...

Loading...