31

Reservoir tank

0.5 liters

(1.1/0.9 US/Imp pt.)

Total

4.7 liters

(10.0/8.3 US/Imp pt.)

CAUTION

!

When changing engine coolant, use mixture of

50% water and 50% anti–freeze for regions

where ambient temperatures fall lower than –16

degrees C (3 degrees F) in winter and mixture of

70% water and 30% anti–freeze for regions

where ambient temperatures do not fall lower

than –16 degrees C (3 degrees F).

Even in regions where no freezing temperature

is anticipated, a mixture of 70% water and 30%

anti–freeze should be used for the purpose of

corrosion protection and lubrication.

COOLING SYSTEM HOSES AND CONNEC-

TIONS INSPECTIONS

1) Visually inspect cooling system hoses for any evi-

dence of leakage and cracks. Examine them for dam-

age, and check connection clamps for tightness.

2) Replace all hoses which show evidence of leakage,

cracks or other damage. Replace all clamps which can-

not maintain proper tightness.

EXHAUST PIPES AND MOUNTINGS

INSPECTION

WARNING

!

To avoid danger of being burned, do not touch

exhaust system when system is hot. Any ser-

vice on exhaust system should be performed

when system is cool.

When carrying out periodic maintenance, or the

vehicle is raised for other service, check exhaust sys-

tem as follows:

Check rubber mountings for damage, deterio-

ration, and out of position.

Check exhaust system for leakage, loose con-

nections, dents and damages. If nuts or bolts

are loose, tighten them to specification. Refer

to below chart for torque specifications.

Check nearby body areas for damaged, mis-

sing, or mispositioned parts, open seams,

holes, loose connections or other defects

which could permit exhaust fumes to seep into

the vehicle.

Any defects should be fixed at once.

Bolts and nuts Tightening torque

Exhaust pipe bolts and

nuts

40–60 N–m

4.0–6.0 kg–m

29.0–43.0 lb–ft

SPARK PLUGS REPLACEMENT

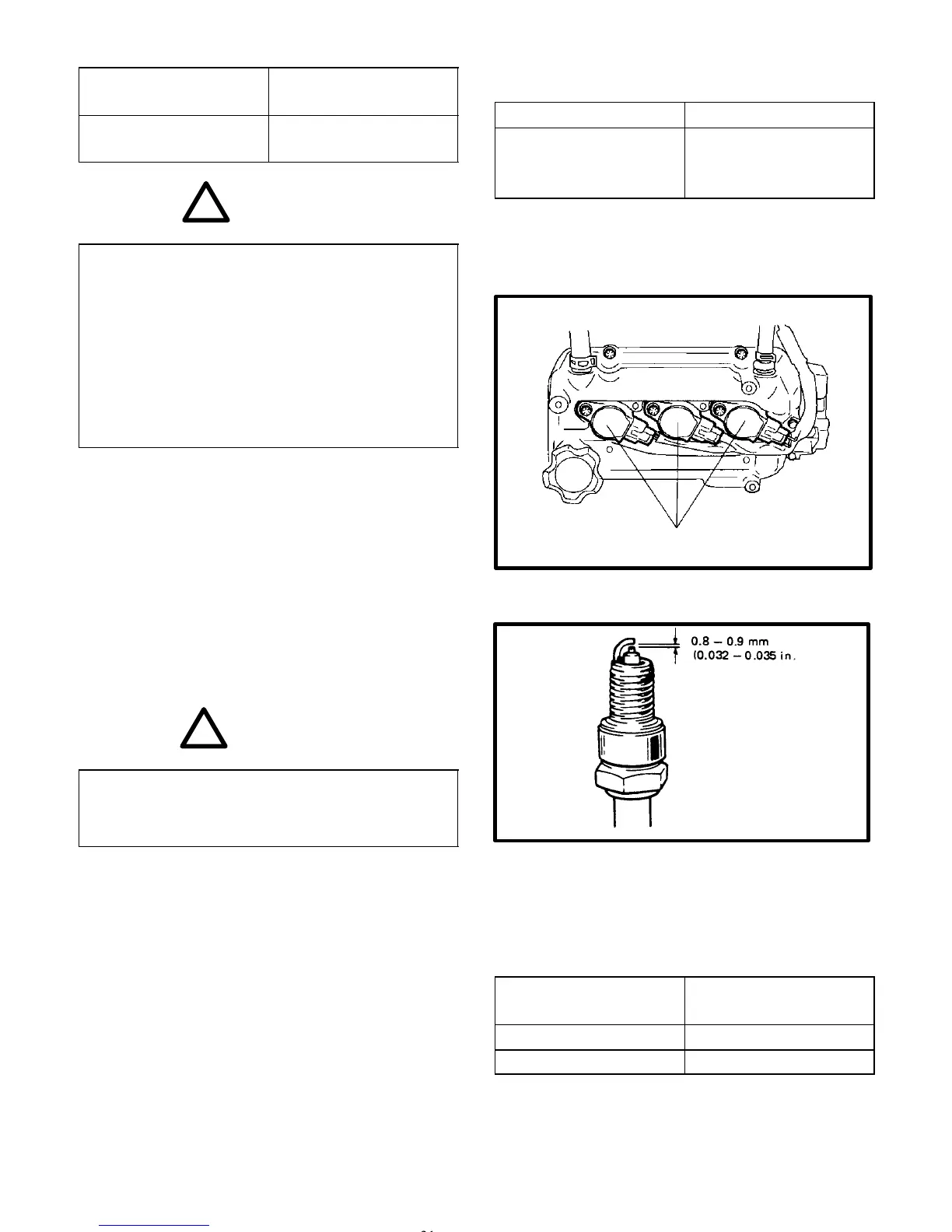

1) Remove scews holding ignition coils, remove ignition

coils.

IGNITION COIL

2) Using a spark plug socket, loosen and remove plugs.

NOTE:

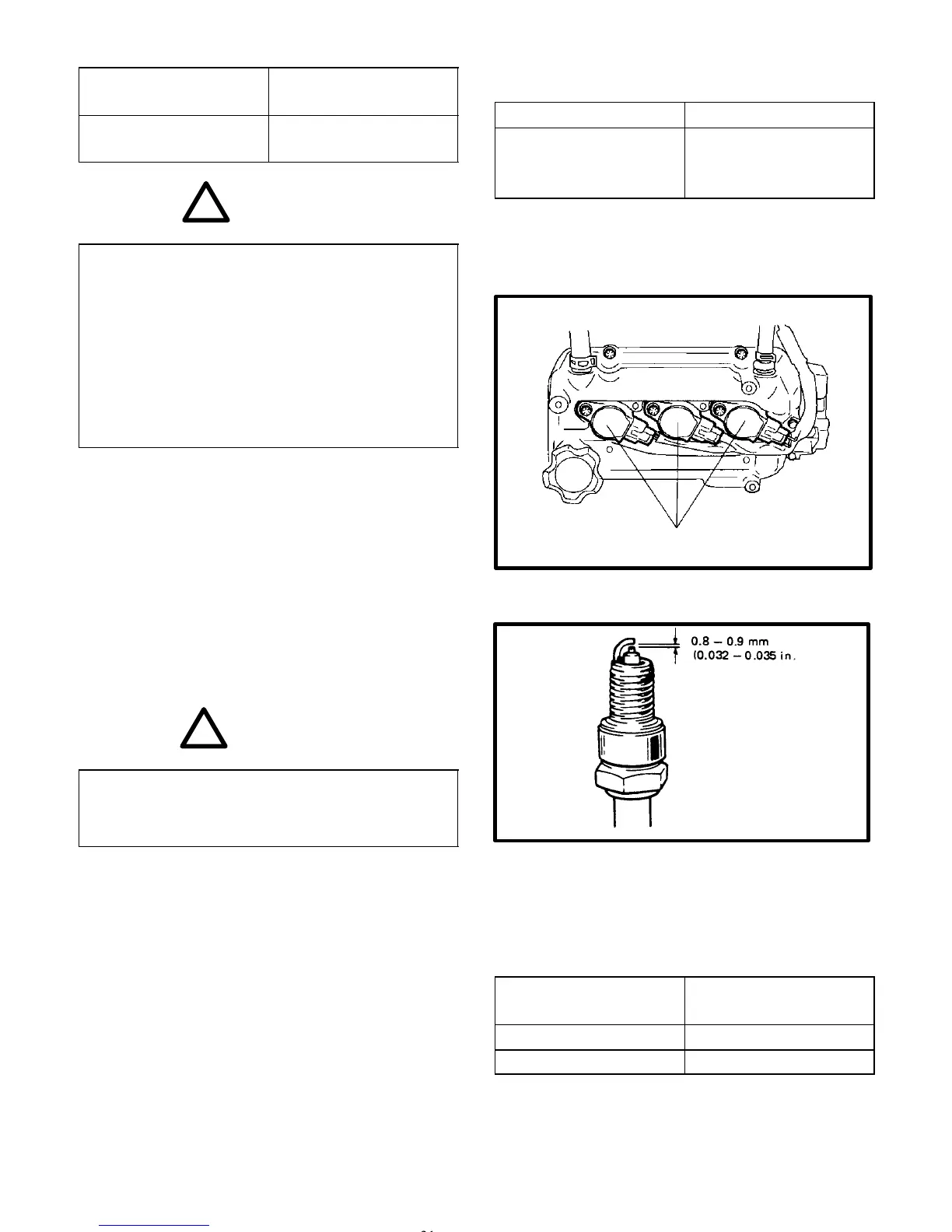

When replacing spark plugs, make sure to use new

plugs of specified heat range and size.

SPARK PLUG SPECIFICATIONS

Manufacturer

Heat Range

Standard type

NGK DCPR7E

Nippondenso XU22EPR–U

3) Install new spark plug. Tighten plugs to specification.

4) Connect ignition coil to spark plugs. Secure with the

orginal hardware.

Loading...

Loading...