72

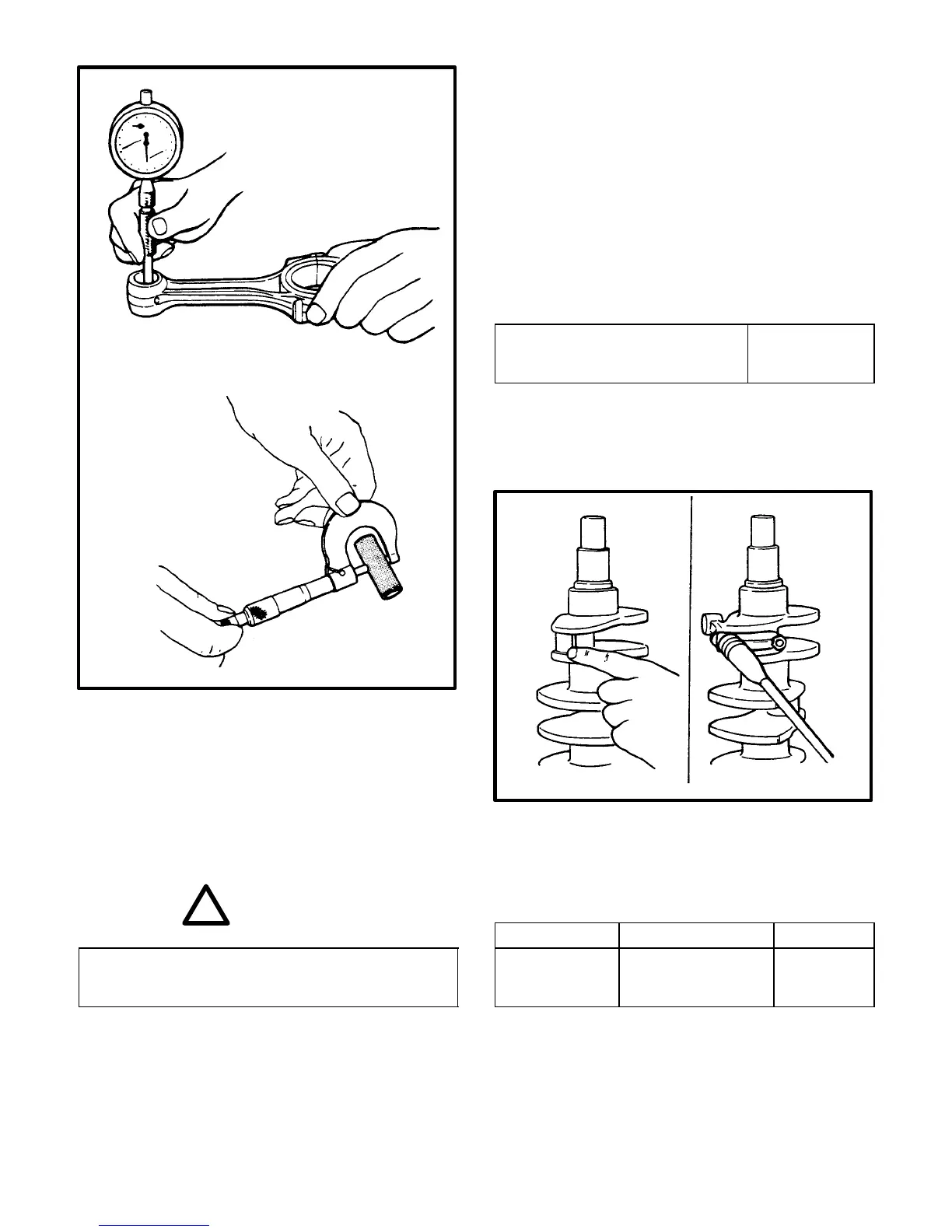

Connecting–rod Big End Bearings

Inspect bearings for signs of fusion, pitting, burn

or flaking and observe the contact pattern. Bear-

ings found in defective condition through this

inspection must be replaced.

CAUTION

!

Bearings are not meant to be repaired by scrap-

ing or sanding with sandpaper or by any

machining. The remedy is to replace them.

Crankpin to bearing clearance:

Check this clearance by using gaging plastic

(Plastigage). Here’s how to use gaging plastic:

1) Prepare by cutting, a length of gaging plastic

roughly equal to bearing width a place it axially

on crankpin, avoiding the oil hole.

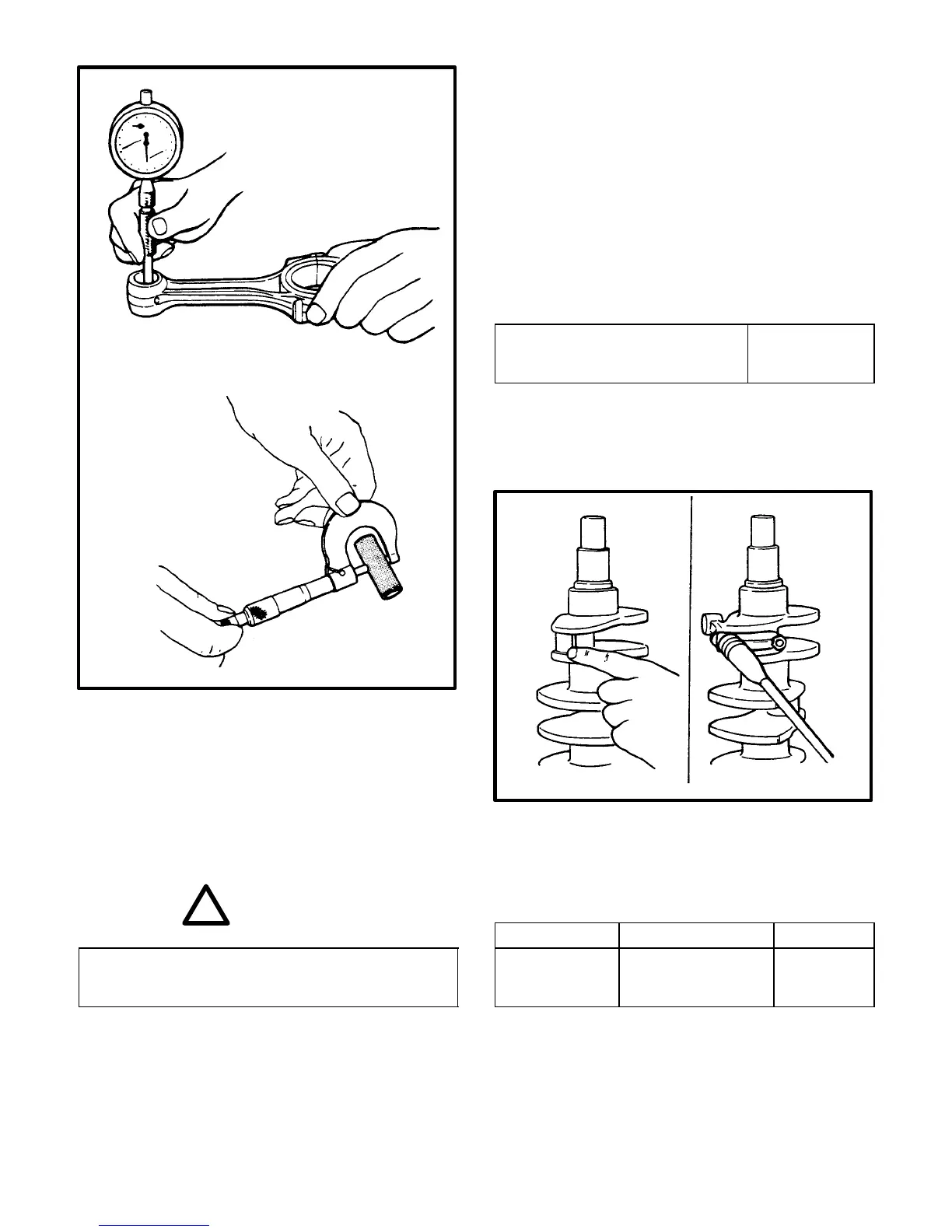

2) Make up the big end in the normal manner,

with bearings in place and by tightening the cap

to the specification.

NOTE:

Never rotate crankshaft or turn rod when a piece of

gaging plastic (Plastigage) is in the radial clearance.

Bearing cap tightening torque

31–35 N–m

3.1–3.5 kg–m

22.5–25.0 lb–ft

NOTE:

When fitting bearing cap to crankpin, be sure to dis-

criminate between its two ends.

3) Remove the cap and measure the width of flattened

gaging plastic piece with the gaging plastic envelope

scale. This measurement must be taken at the widest

part.

Item Standard Limit

Crankpin–to–

bearing clear-

ance

0.020–0.040 mm

(0.0008–0.0016 in.)

0.065 mm

(0.0025 in.)

Loading...

Loading...