66

Valve Seats

CAUTION

!

Valves to be checked and serviced for seating

width and contact pattern must be those found

satisfactory in regard to stem clearance in the

guide and also requirements stated on preced-

ing page under VALVES.

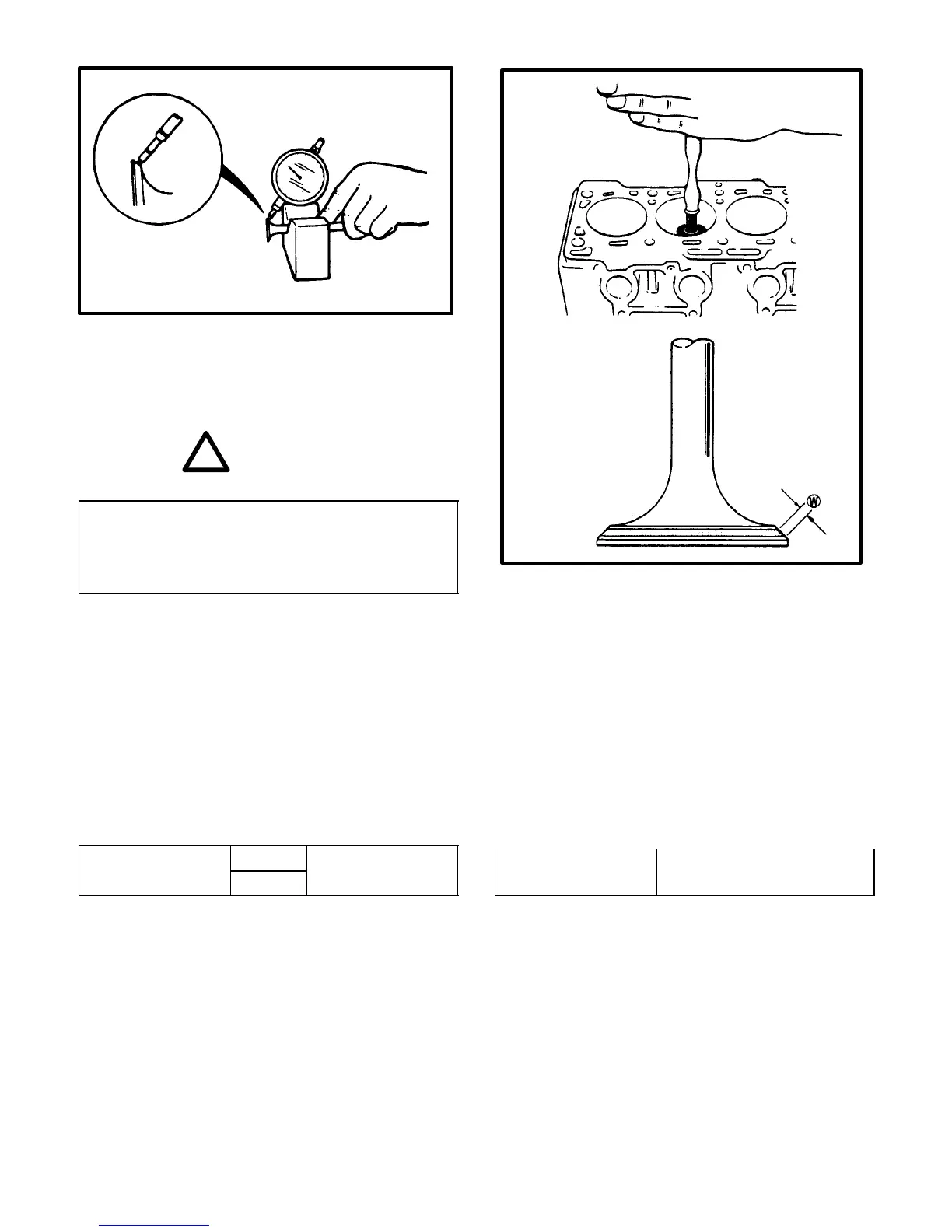

Seating contact width: Produce a contact pat-

tern on each valve in the usual manner, namely,

by giving a uniform coat of marking compound

(red–lead paste) to valve seat and by rotatingly

tapping seat with valve head. Valve lapper tool

(tool used in valve lapping) must be used.

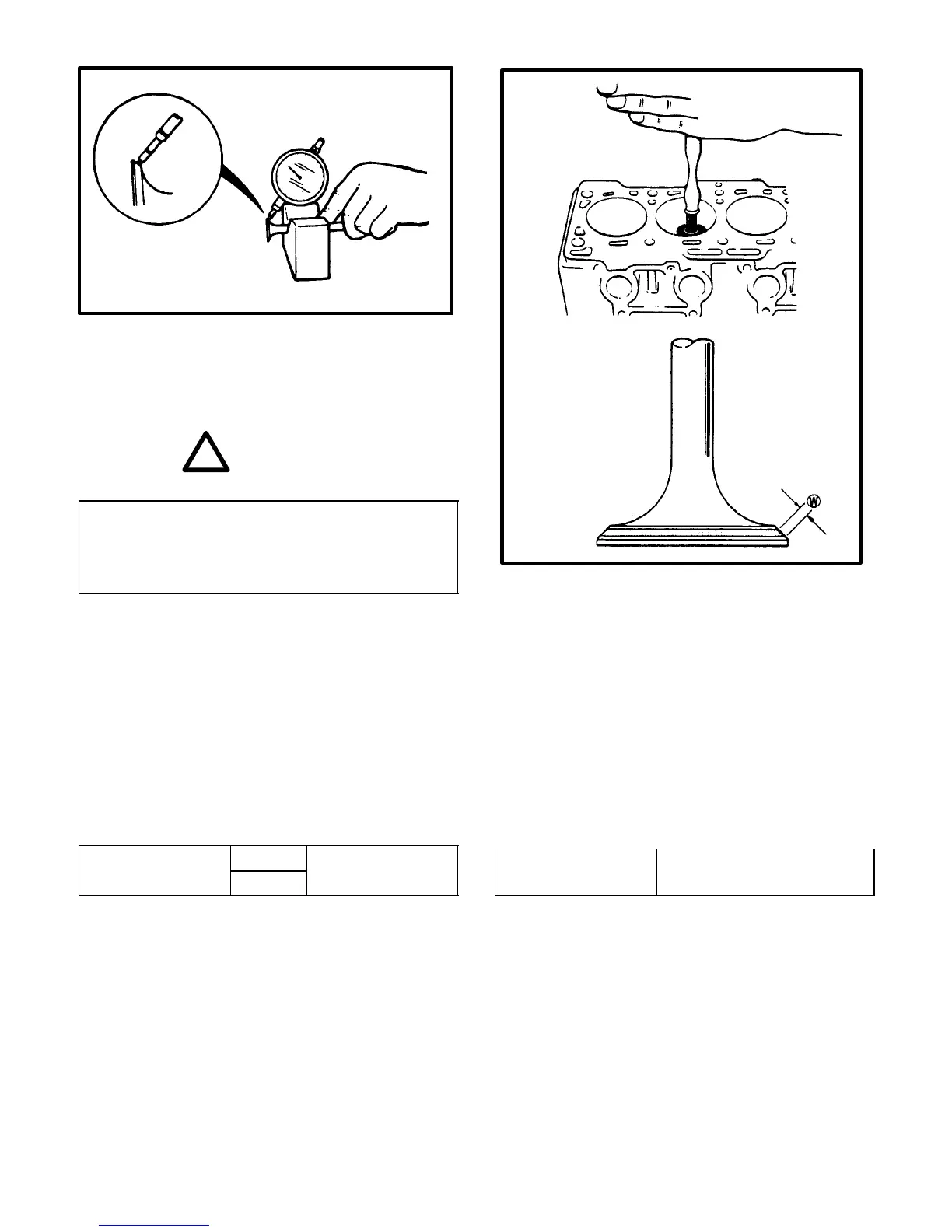

The pattern produced on seating face of valve

must be a continuous ring without any break,

and width (W) of pattern must be within stated

range as follows.

Standard seating width

Intake

1.1 – 1.3 mm

revea

e

y con

ac

pattern on valve face

Exhaust

(0.0434 – 0.0511 in.)

Valve seat repair: Valve seat not producing uni-

form contact with its valve or showing a width

(W) of seating contact that is off the specified

range must be repaired by re–grinding or by cut-

ting and regrinding and finished by lapping.

1) EXHAUST VALVE SEAT: Use a valve seat

cutter to make three cuts as shown below figure.

Three cutters must be used: The first for making

15° angle, the second for making 60° angle and

the last for making 45° seat angle. The third cut

must be made to produce the desired seat width

(W).

Seat width (W) for

exhaust valve seat

1.1 –1.3 mm

(0.0434 – 0.0511 in.)

Loading...

Loading...