140

INSPECTION OF COMPONENTS

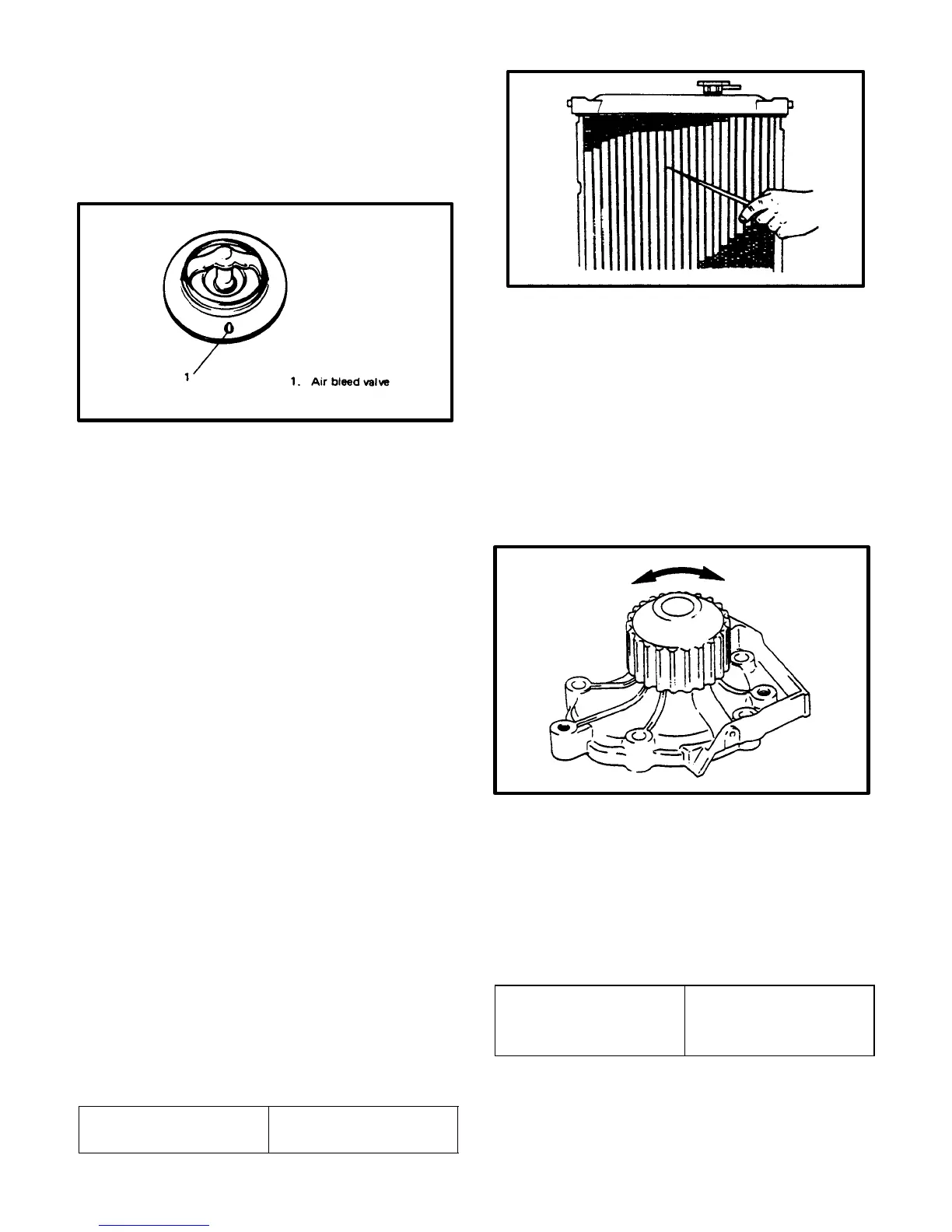

Thermostat

1) Make sure that the air bleed valve of thermostat is

clear. Should this valve be clogged, engine would tend

to overheat.

2) Check valve seat for some foreign objects being stuck

which might prevent valve from seating tight.

NOTE:

Check interference between water tempature sensor

and thermostat.

3) Check thermostatic movement of wax pellet as fol-

lows:

Immerse thermostat in water, and heat

water gradually.

Check the the valve starts to open at speci-

fied temperature.

If valve starts to open at a temperature

substantially below or above specification,

thermostat unit should be replaced with a

new one. such a unit, if re–used, will bring

about overcooling or overheating ten-

dency.

Radiator

If water side of the radiator is found excessively rusted

or covered with scales, clean it by flushing with radiator

cleaner compound. This flushing should be carried out

at regular intervals due to scale or rust formation advanc-

ing with time.

Inspect radiator cores and straighten any flattened or

bent fins. Clean cores, removing dirt and any debris.

Excessive rust or scale formation inside of radiator low-

ers cooling efficiency. Flattened or bent fins obstruct flow

of air through the core to impede heat dissipation.

Radiator Flushing

Interval

Two years

(recommended)

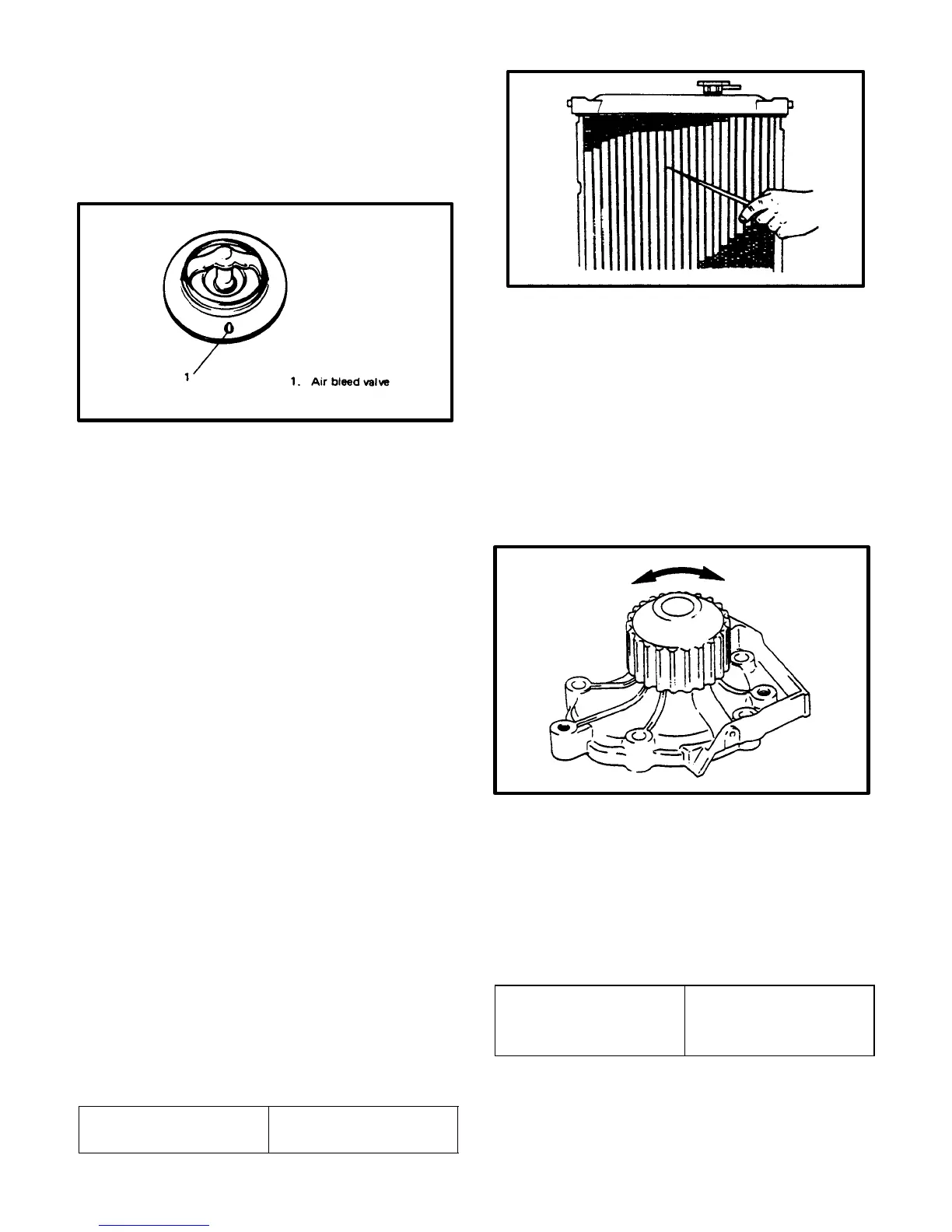

Water Pump

NOTE:

Do not disassemble water pump.

If any repair is required on pump, replace it as an

assembly.

Rotate water pump by hand to check for

smooth operation.

If pump does not rotate smoothly or makes an abnormal

noise, replace it.

IMPORTANT STEPS FOR REINSTALLA-

TION

Water Pump

1) Install new pump gasket to cylinder block.

2) Install water pump to cylinder block.

Tightening torque for

nuts and bolts

9–12 n–m

0.9–1.2 kg–m

7.0–8.5 lb–ft.

3) Remove cylinder head cover and loosen all valve

adjusting screws of intake and exhaust rocker arms fully.

4) Install belt tensioner, tensioner spring, timing belt and

outside cover.

Loading...

Loading...