173

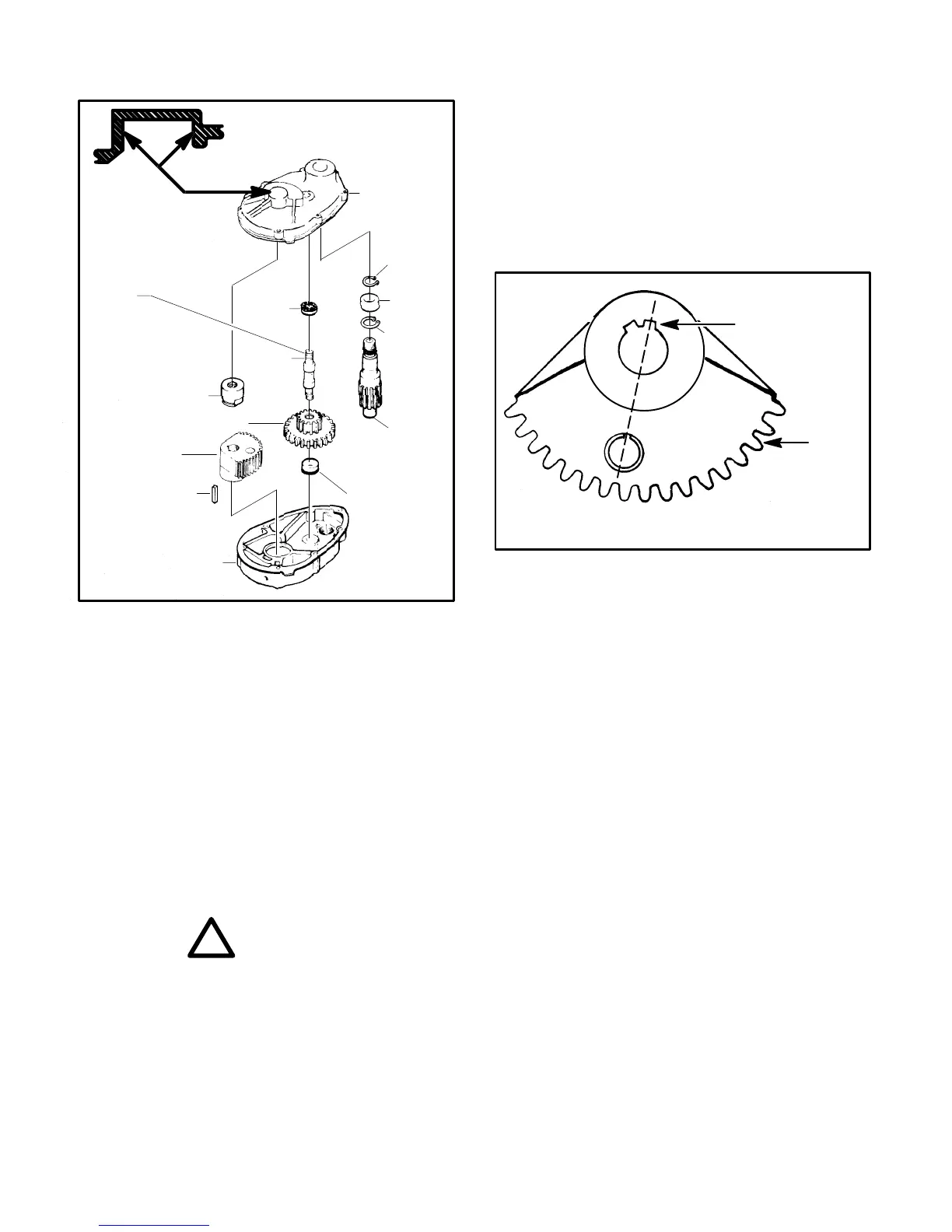

STEERING GEAR

Driven

Steering Gear

INSIDE SURFACE

MACHINED TO

PROVIDE CLEARANCE

FOR NUT

IDLER

BOLT

WITHOUT

LUBRICATION

FITTING

Key

Upper

housing

Lower housing

FIGURE 15

Pinion

Gear

Shaft

Washer

Cluster Gear

Nut

Washer

Retaining

Ring

Ball

Bearing

Bolt

Retaining

Ring

Disassembly

With the horn wire disconnected, remove the horn button

and lift wire from the pinion shaft.

Remove the steering wheel retaining nut and lift the

wheel from the shaft.

Remove the top idler bolt nut and washer and the gear

case retaining screws. The case may now be lifted off.

Remove the driven gear nut. The gear may now be

removed by the use of a 1/2–20 knock–off (obtainable

through your Cushman dealer).

Remove the lower idler bolt nut and washer and lift the

cluster gear and idler bolt from the lower case.

!

CAUTION

• Inspect all gears and splines for wear or dam-

age. If the wear or damage is excessive, replace

with new parts. Also inspect the pinion shaft for

wear.

Reassembly

Place a locating washer, with the knurled side down, over

the hole for the idler adjustment bolt. Insert the adjust-

ment bolt, add another locating washer on the outside of

the lower housing with the knurled side against the hous-

ing. Secure with a nut and tighten finger tight. See Figure

15.

Place a liberal amount of lubrication in recess of idler

adjusting bolt and place the cluster gear over the idler

adjusting bolt.

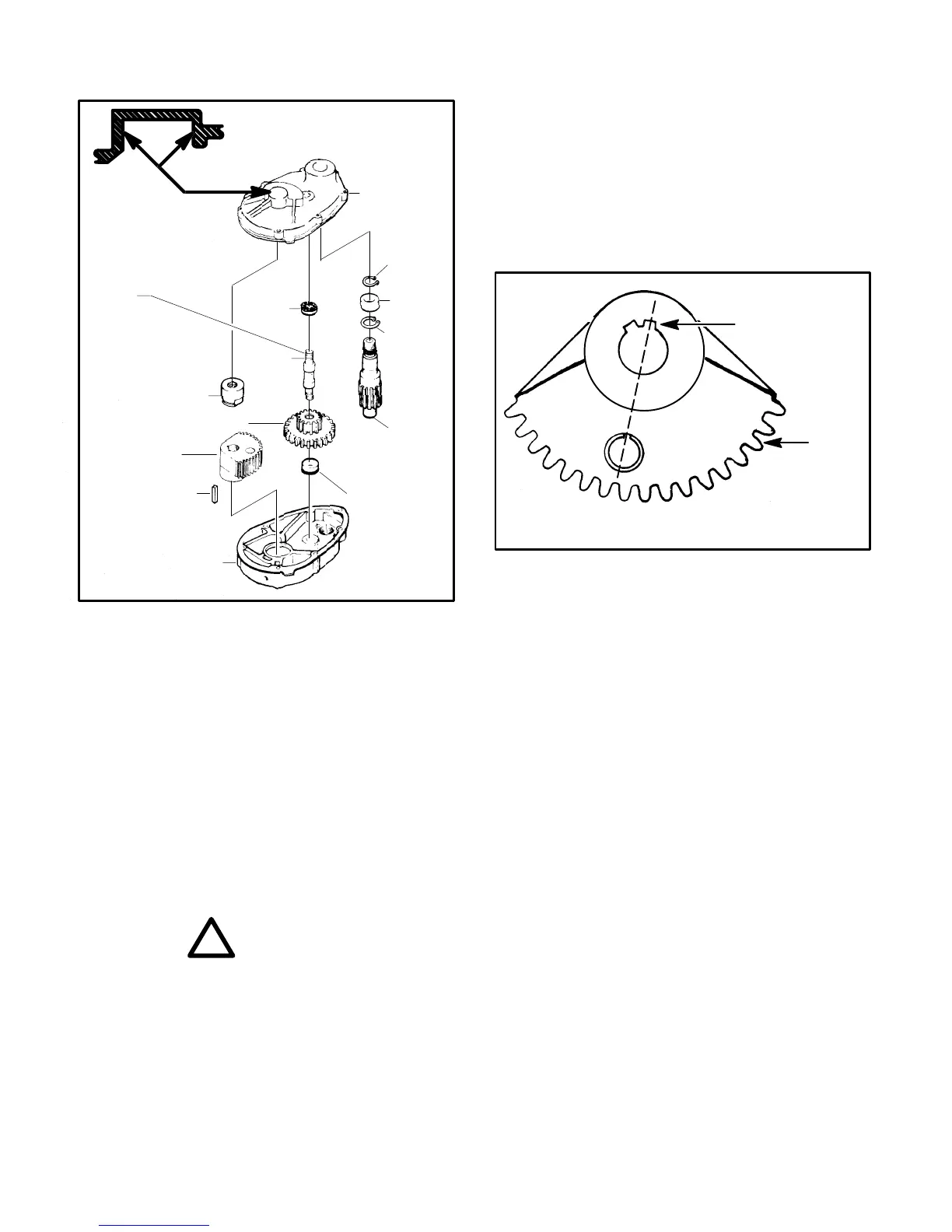

Determine the correct keyway in the driven gear (see

Figure 16 below) and install gear. Torque the steering

bushing nut to 40–50 ft.–lbs. (54 –70 N⋅m). Apply a liberal

amount of lithium based lubricant to the gear teeth and

all bearing surfaces.

Ref.

Driven

Gear

Part

No.

830167

Use this keyway

(Viewed from top of gear)

FIGURE 16

Adjust the height of the lower housing as shown in Figure

17 (page 22). Tighten the support mounting screws.

Tighten the five lower housing and support bracket

screws to 20–25 ft.–lbs. (27–34 N⋅m).

Place one locating washer, knurled side up, over the idler

adjustment bolt. Assemble upper housing to lower hous-

ing. Place another locating washer over the adjustment

bolt with the knurled side against the upper housing.

Secure with a nut and tighten finger tight. Tighten hous-

ing attaching screws to 8–10 ft.–lbs. (11–14 N⋅m).

Backlash Adjustment

The weight of the vehicle must be on the wheels or hold

the front wheel to prevent the fork from turning. Loosen

the upper and lower idler bolt adjusting nuts, turn the

steering wheel counterclockwise and hold with light pres-

sure. Snug the lower idler adjusting nut and then the

upper adjusting nut. Use a socket wrench and at least a

4” (101.6 mm) extension. Care MUST be exercised to

avoid cocking the idler bolt. With slight pressure on the

steering wheel in counterclockwise direction, tighten

lower nut 40–50 ft.–lbs. (54–70 N⋅m). Check backlash for

a maximum of 1/4” (6.4 mm) travel of the steering wheel

rim, then tighten upper adjusting nut 40–50 ft.–lbs.

(54–70 N⋅m). Check operation of the steering for free

operation. A slight amount of roughness is permitted

after the front fork and wheel has been rotated either

Loading...

Loading...