6.1.4.3 PROCEDURE TO FOLLOW IF A FEW SLATS ARE WORN BUT

THE BELTS ARE IN A GOOD CONDITION

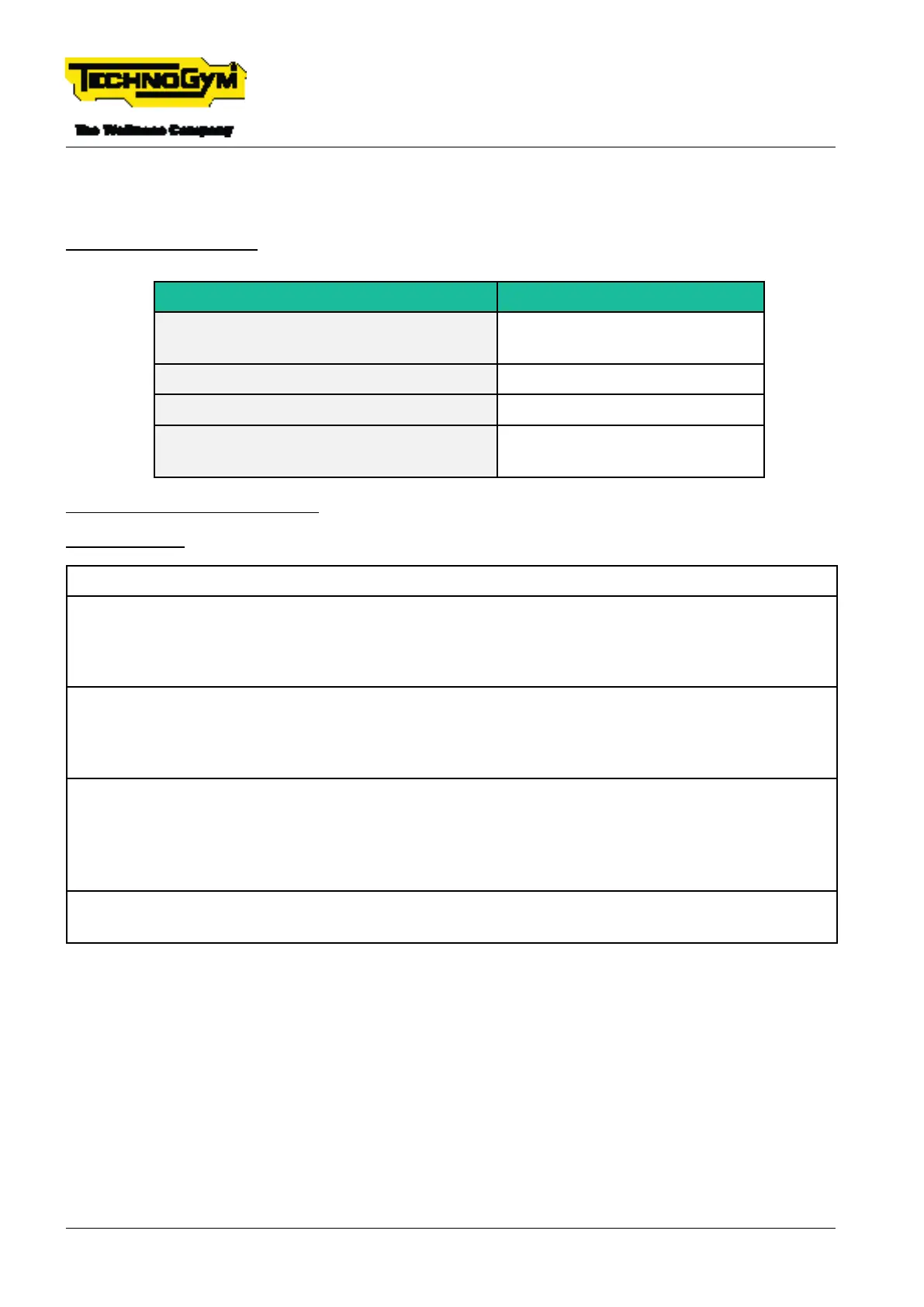

Necessary components:

COMPONENT Q.TY

Plates (to be positioned between the slats

and the self-locking nuts)

2 for each replaced slat

Self-locking nuts 4 for each replaced slat

Rubber strips 1 rubber strip for every 10 slats

Slats the quantities depends on the

number of slats to replace

Number of technicians required: 1

PROCEDURE:

1. Turn o the equipment. Disconnect the power supply cable.

2. Remove the front and side casing, on the right and left side of the equipment.

For details, refer to the disassembly procedure (see the attached video):

13 - Disassembling the bottom casing

3. Remove the front and rear footrest guard, on the right and left side of the equipment.

For details, refer to the disassembly procedure described in the chapter:

$7.22 DISASSEMBLING THE FRONT AND REAR ROLLER

4. Remove the worn slats from the belts. If necessary, remove the rubber strips between the

belt and slats.

For details, refer to the disassembly procedure (see the attached video):

18 - Remove slats

5. If necessary, insert the rubber strips between the belts and slats. Fit the new slats with the

new self-locking nuts and the new plates.

TECHNOGYM RUN Technical Service Guide

Rev. 1.0

- 64 - TSG-00284-EN- Uncontrolled copy if printed

Loading...

Loading...