5-39

Electronic Gear Ratio setting examples

Transmission System Setting Process

Ball Screw

Pulse Value of 1 Rotating for

Encoder=2000pulse/rev

Distance of 1 Rotating for Ball

Screw = 5mm

1. Main positioning specifications:

a) Load Shaft(Ball Screw) pitch

move distance per revolution= 5mm

b) Motor Encoder ppr ( Pulse per revolution) =

2000pulses

2. Move distance per one pulse of move Command.

Moving Distance of 1 Pulse Command =1μm

3. Calculation of the Electronic Gear Ratio:

5000

8000

/1/5

4/2000

RationGear Electronic =

÷

×

=

pulseumrevmm

revpulse

4. Set the parameter of Electronic Gear Ratio:

Numerator of Electronic Gear Ratio = 8000

Denominator of Electronic Gear Ratio = 5000

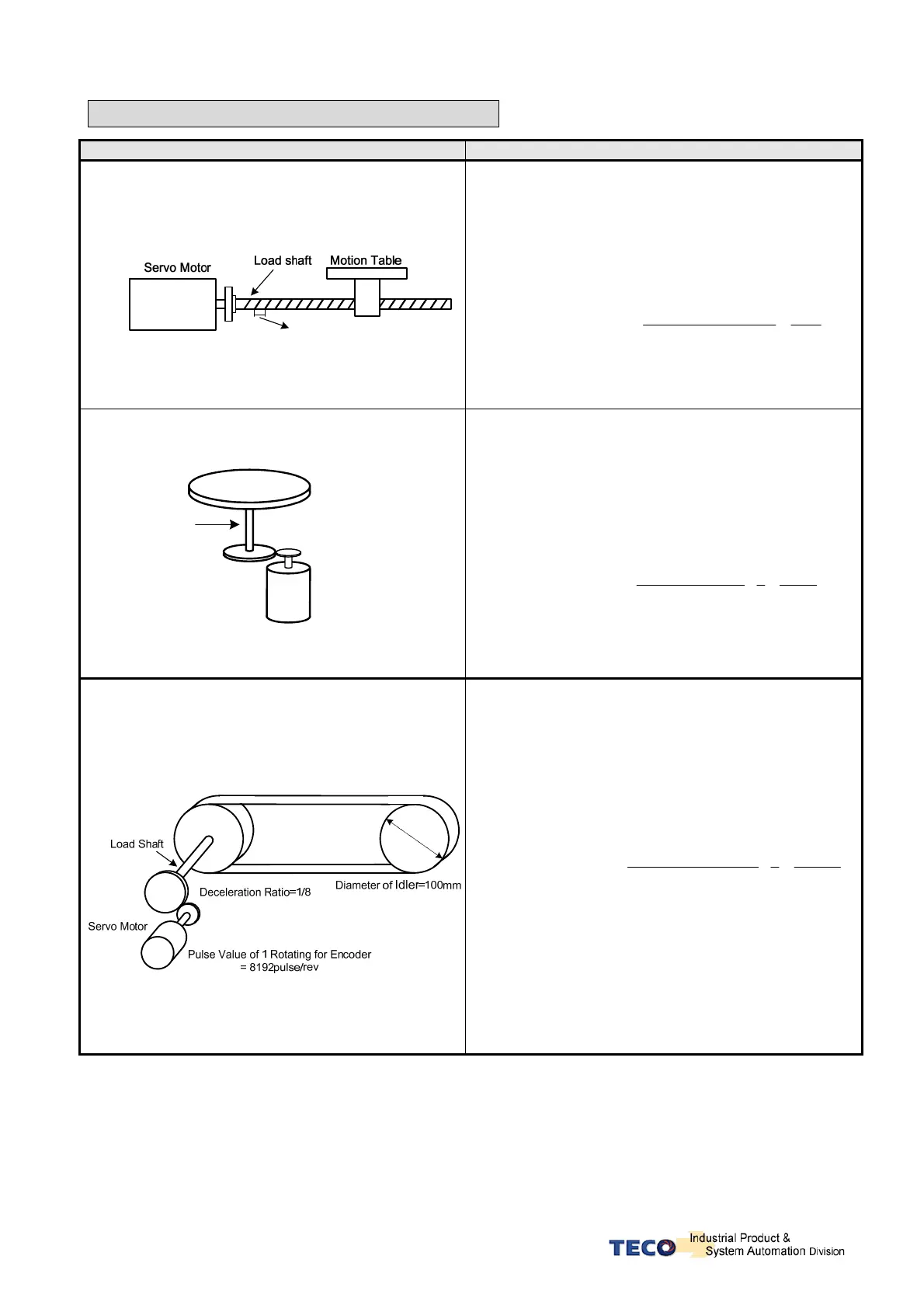

Mechanical Disc

Load Shaft

Deceleration Ratio-1/5

Servo Motor

Pulse Value of Rotating for Encoder

= 2500pulse/rev

1. Main positioning specifications:

a) Deceleration Ratio=1/5

b) Load Shaft(Mechanical Disc)Move Value per one

revolution=360 ゚

Motor Encoder ppr ( Pulse per revolution)= 2500 pulses

2. Move distance per one pulse of move Command.

Distance for 1Pulse Command =0.1 ゚

3. Calculation of the Electronic Gear Ratio:

3600

50000

1

5

/1.0360

4/2500

RatioGear Electronic =×

°÷°

×

=

pulse

revpulse

4. Set the parameter of Electronic Gear Ratio:

Numerator of Electronic Gear Ratio = 50000

Denominator of Electronic Gear Ratio =3600

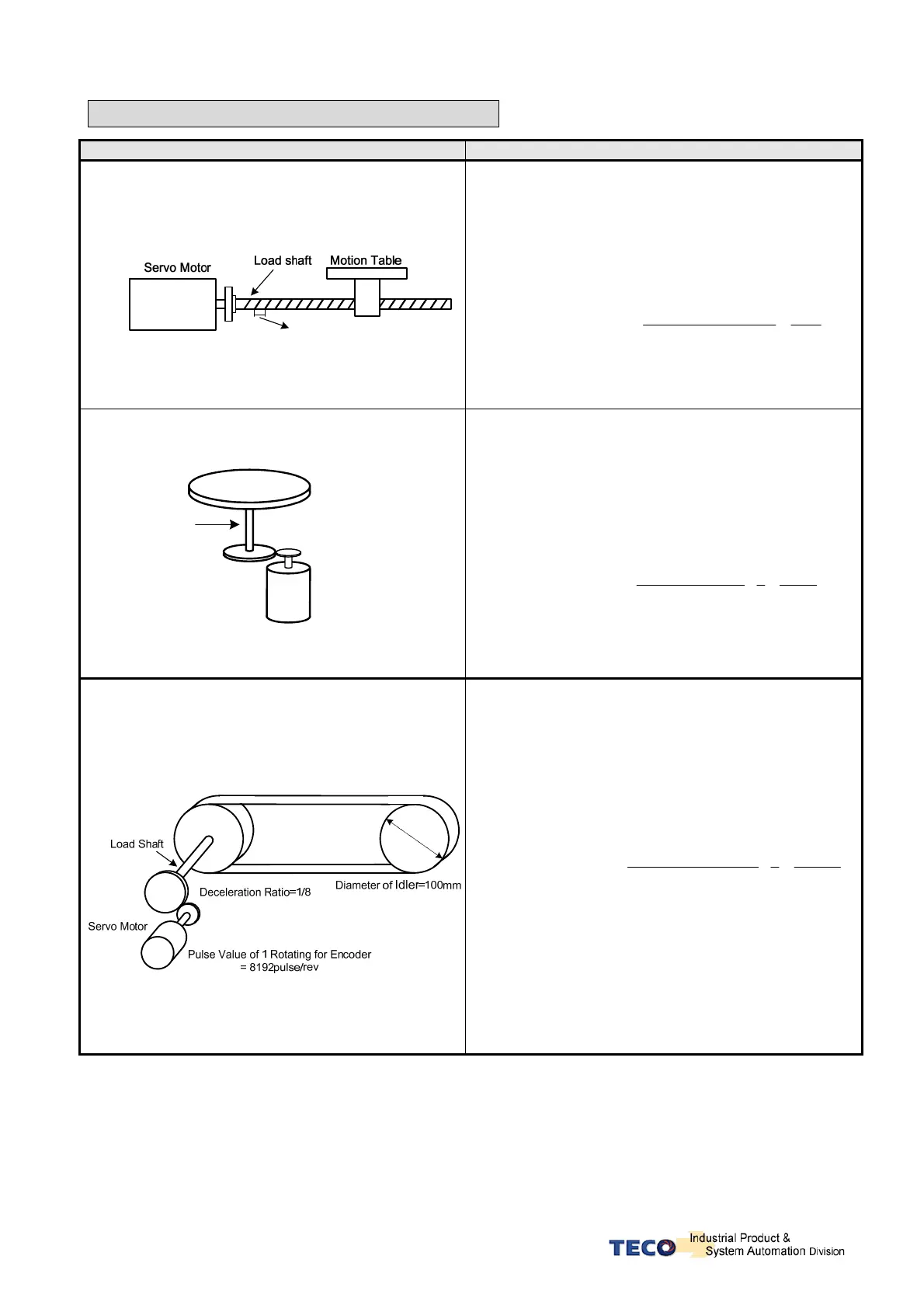

Transmission Belt

1. Main positioning specifications:

a) Deceleration Ratio=1/8

b) Load Shaft ( Idler)

Move Value per revolution.

mm314mm1003.14

c) Motor encoder ppr ( Pulse Per Revolution) =

8192pulse

2. Move distance per pulse of move Command.

Distance for 1Pulse Command =10μm

3. Calculation the Electronic Gear Ratio:

31400

262144

1

8

/10314

4/8192

RatioGear Electronic =×

÷

×

=

pulseummm

revpulse

4. Set the parameter of Electronic Gear Ratio:

Reduction of the fraction to make the Numerator and

Denominator less than 50000.

Numerator of Electronic Gear Ratio

32768

Denominator of Electronic Gear Ratio

3925

Loading...

Loading...