4-26

Model 3550 LCR Meter Instruction Manual Operating Instructions

Making Accurate Measurements cont’d:

Zero Corrections

Residual Impedance and Leakage of test fixtures exists for all types of test fixtures. To maintain

the performance accuracy of the 3550 it is highly recommended that a zero correction be

performed whenever a change in test fixture takes place. For test fixtures such as Kelvin Klip

Leads where the positioning may vary, extra effort must be made to perform the zero correction

while positioning the leads in the exact location, as the measurement will be taken.

When performing a standard zero correction, the instrument will step through frequencies from

42Hz to 5MHz. This takes a considerable amount of time and may not be desired in certain

applications especially when the actual component test will take place at a single frequency point.

To overcome this, the 3550 has the ability to perform spot frequency corrections where zero

corrections are performed on up to three user defined frequency set points. The spot frequency

zero correction data is stored in the instrument’s non-volatile RAM and will overwrite any

correction data obtained from a standard zero correction procedure. A standard zero correction

cannot write over data from a spot frequency zero correction. The spot frequency setting must be

disabled in order for the standard zero correction to be able to write over all frequency points.

Refer to “Defining Spot-Correction Frequencies for Zero Adjustments”, [SHIFT] ĺ [8] in the front

panel description to learn how to enable or disable the spot frequency settings.

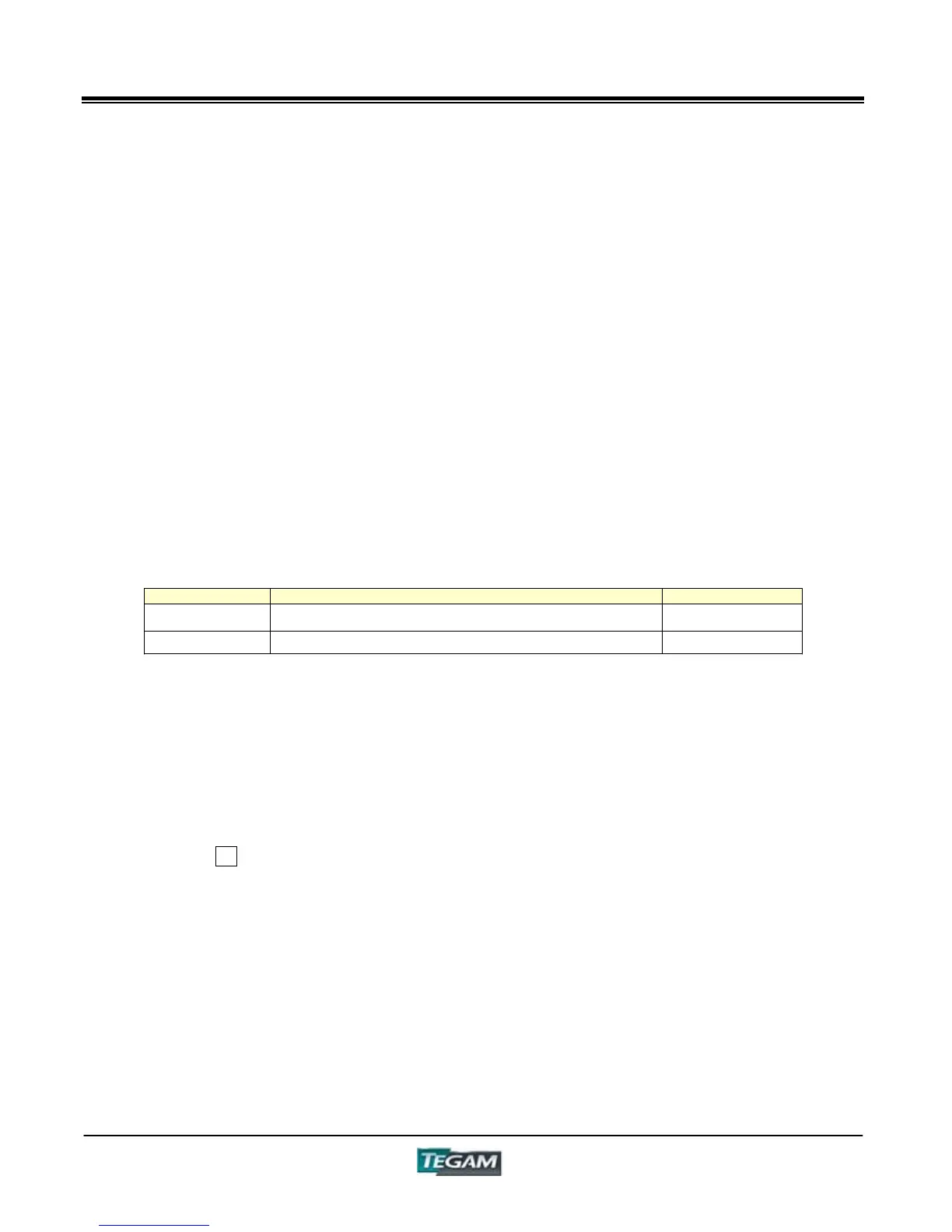

Table 4.6 - Zero Correction Limits

Zero Correction Correction Correction Limit

Open Stray Capacitance & Stray Conductance (C0)&(G0) >1kƻ

Short Residual Inductance & Residual Resistance (L0)&(R0) < 1kƻ

If during OPEN correction the Impedance is less than 1kƻ, or during SHORT correction the

Impedance is 1kƻ or higher, a buzzer will go off to warn that correction cannot be made, and

the system will reset without making the correction.

There are three methods of defining what frequencies a zero correction will be performed on. They

are Standard, Frequency Limit, and Spot Frequency Zero Correction.

Standard Zero Correction

Refer to Section 4 , “ZERO” Panel – for instructions to perform a standard open and short circuit

correction. This procedure will perform a zero correction on all test frequencies, 42Hz~5MHz

except for those designated as spot correction frequencies.

Frequency Limit Zero Correction

For zero correction, [SHIFT] ĺ [-], Correction Frequency Limit Setting Mode allows the user to

define the upper and lower frequency limits instead of using the default 42Hz~5MHz range.

Spot Frequency Zero Correction

Refer to [SHIFT] ĺ [OPEN] and [SHIFT] ĺ [SHORT] sections for instructions to perform a spot

frequency open and short zero correction procedure.

After performing the zero correction procedure, perform a “before and after” measurement on a

component with an accurately known value to confirm that a zero correction has taken place. A

calibrated capacitance or inductance standard would be ideal (but not required) for this type of

verification.

Loading...

Loading...