C

LEAR

P

ATH

U

SER

M

ANUAL

R

EV

.

1.97

52

S

ETTING

PWM

etting” by ClearPath. This gives the user

M

gh” to) 50%.

A

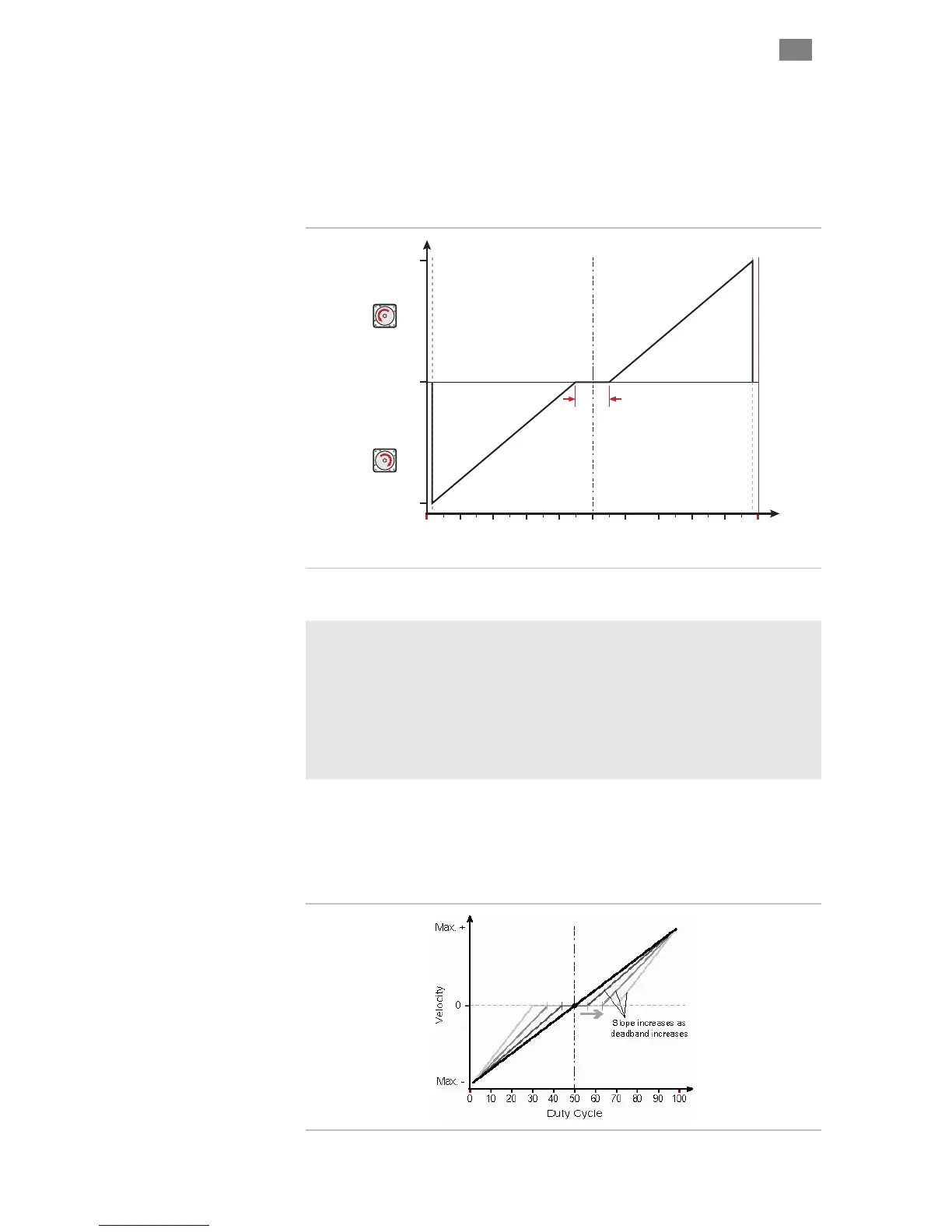

The deadband expands the range about the 50% PWM mark that is

n erpreted as the “zero-velocity s

D

EADBAND

(O

PTIONAL

)

i t

a reliable way to ensure that motor velocity ramps to zero when the PW

duty cycle is set at (or “close enou

Max. Velocity

(CCW Rotation)

Velocity = 0

Deadband

(+/- 5%)

10 20 30 40 50 60 70 80 90 1000

Max. Velocity

(CW Rotation)

Duty Cycle

+/- 5% PWM dead band setting

Why use a deadband?

In bi-polar mode, stopping the motor (i.e. commanding “zero velocity”) is

achieved, in theory, by applying a 50% duty cycle PWM signal to Input B.

However, it can be technically challenging to set a perfect 50% duty cycle.

In fact, some very low speed motion may still be observed at the motor

shaft even when duty cycle is apparently set to 50%. A deadband helps to

ensure that actual motor velocity is zero (with no drift) when you expect it

to be.

Example: If the user sets a +/- 5% dead band, any PWM signal with a

duty cycle between 45% and 55% will be interpreted as a zero-velocity

command by ClearPath. See figure above.

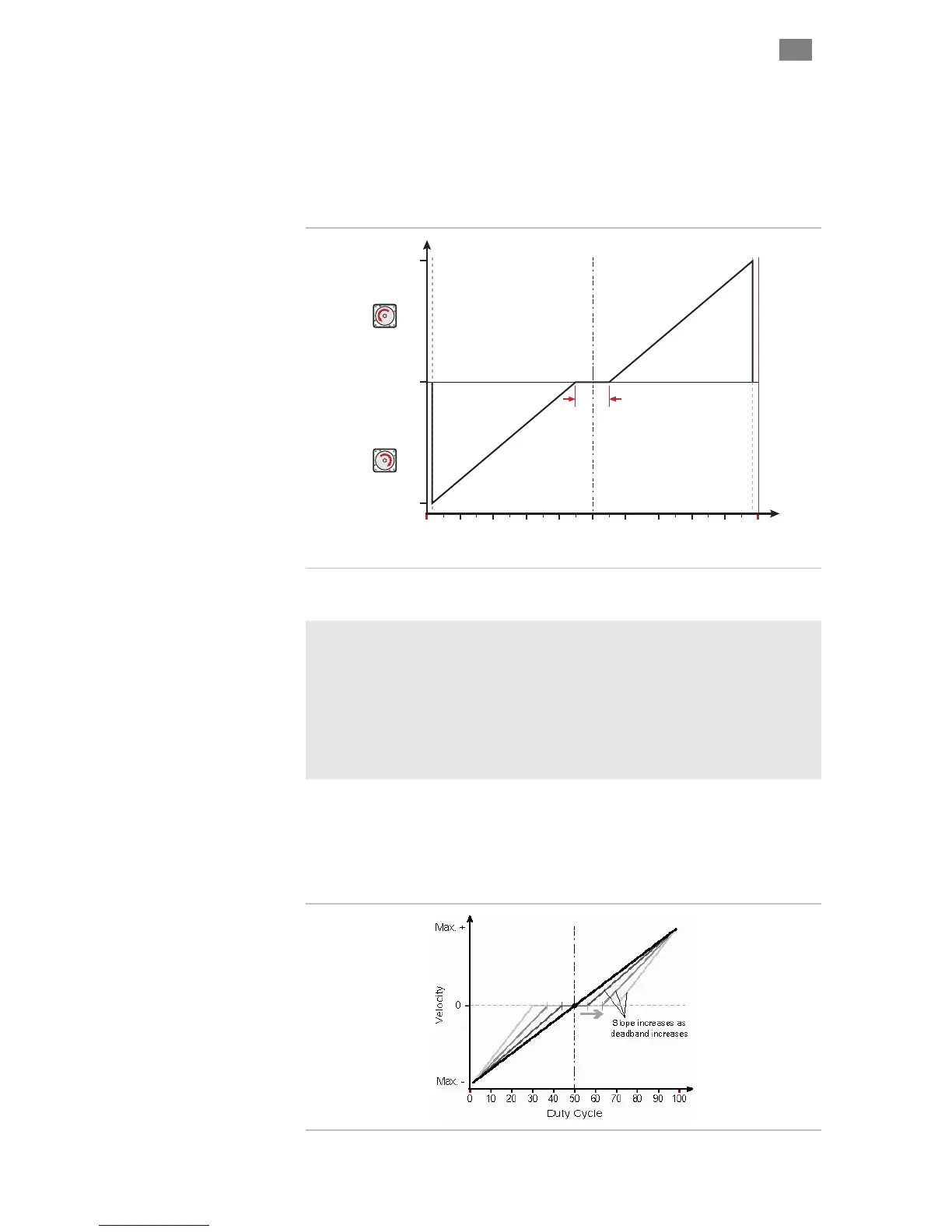

Note: As size of deadband setting increases, the slope of velocity vs. duty

cycle increases as illustrated below.

T

EKNIC

,

I

NC

.

F

AX

(585)784-7460

V

OICE

(585)784-7454

Loading...

Loading...