Getting Started

Signal connec

tions

Before you connect signals to the ECO8000 Series, create a table similar to the

one shown below so that you can plan which signals need to connect to which

channels on t

he ECO8000 Series.

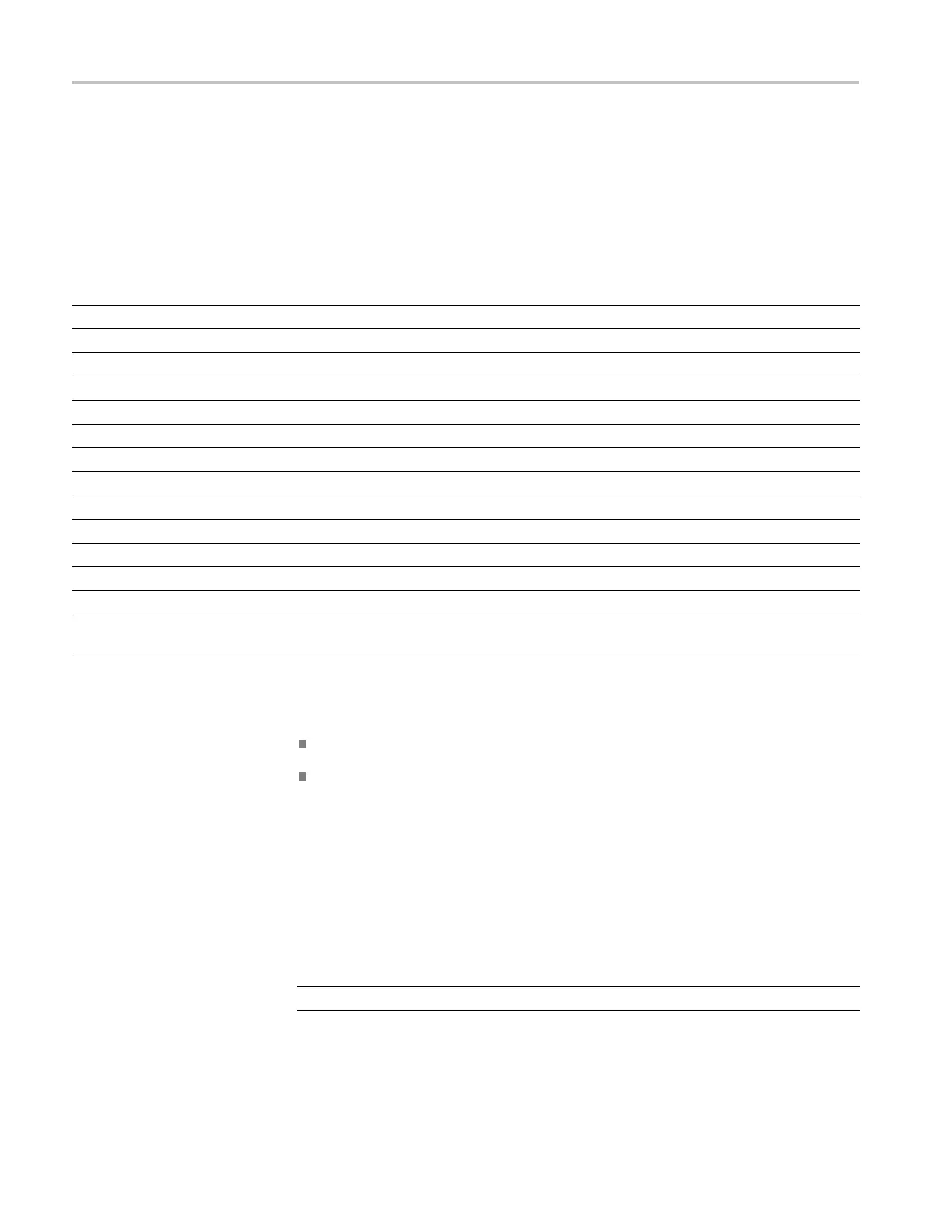

Table 4: Example plan for connecting signals to an ECO8000

Channel Channel type Signal source Destination Signal format Notes

1

REF (ELSW)

Black 1

Studio 1 NTSC

2

REF (ELSW)

Black 2

Studio 2

PAL

3

REF (ELSW)

Black 3 Basement 1080i59

4

REF (ELSW)

Black 4

MC Tri

1080i50

5

REF (ELSW)

Black 5 Truck 1 1080i60

6

REF (ELSW) Word Clock MC WC

5V

7

HREF (Relay) Silence Sound room AES

2.5, 2.3 dB

8

HREF (Relay) SDI 1 MC SD BARS SD 525

9

HREF (Relay) SDI 2 MC HD BARS

HD 1080i59

LTC1 LTC

0.5 V

MC LTC

30 DF

LTC2 LTC

1V

Studio 1 LTC

30 DF 4 dB

LTC3 LTC

2V

Studio 2 LTC 25 FPS

LTC4 LTC

5V

Basement LTC

30 DF

SPG trigger Loss of lock,

hardware error

Channel type connection guidelines. When connecting signals to the instrument,

use the following guidelines:

Use REF (ELSW) channels to connect non-SDI signals

Use HREF (Re lay) channels to connect SDI signals

You c an connect non-SDI signals to HREF (Relay) channels. However, there will

be a sync interruption when primary/backup source switches occur.

Recommended tools. The ECO8020 uses HD BNC connectors. Due to the

tight spacing between c onnectors, it is recommended that you use a HD BNC

installation/removal tool to connect or disconnect cables on these connectors.

Listed below is one source where you can obtain this tool.

Manufacturer Part number

Amphenol

®

RF (www.amphenolrf.com)

227–T2000

12 ECO8000 Series Automatic Changeover Unit User Manual

Loading...

Loading...