Operating Basics

Operational o

verview

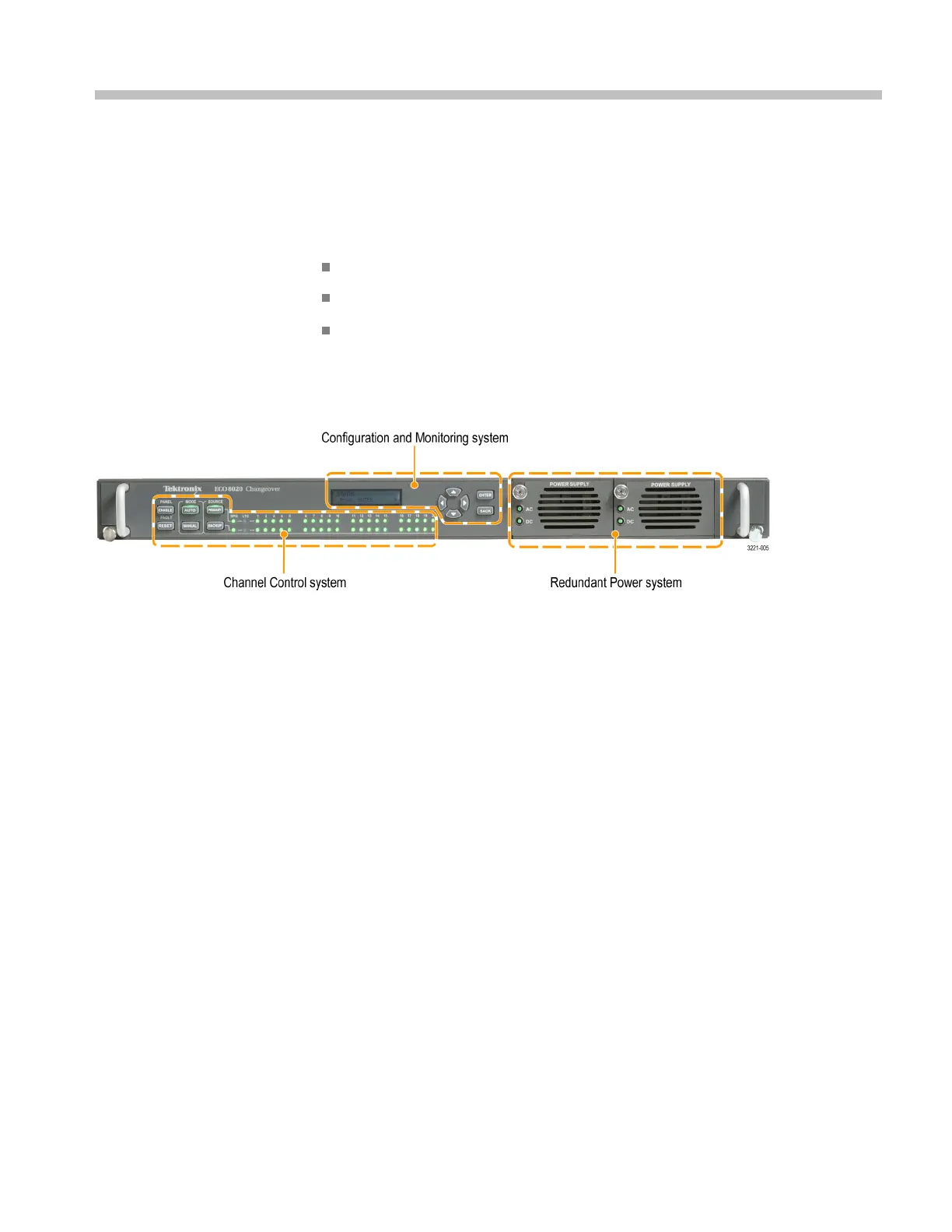

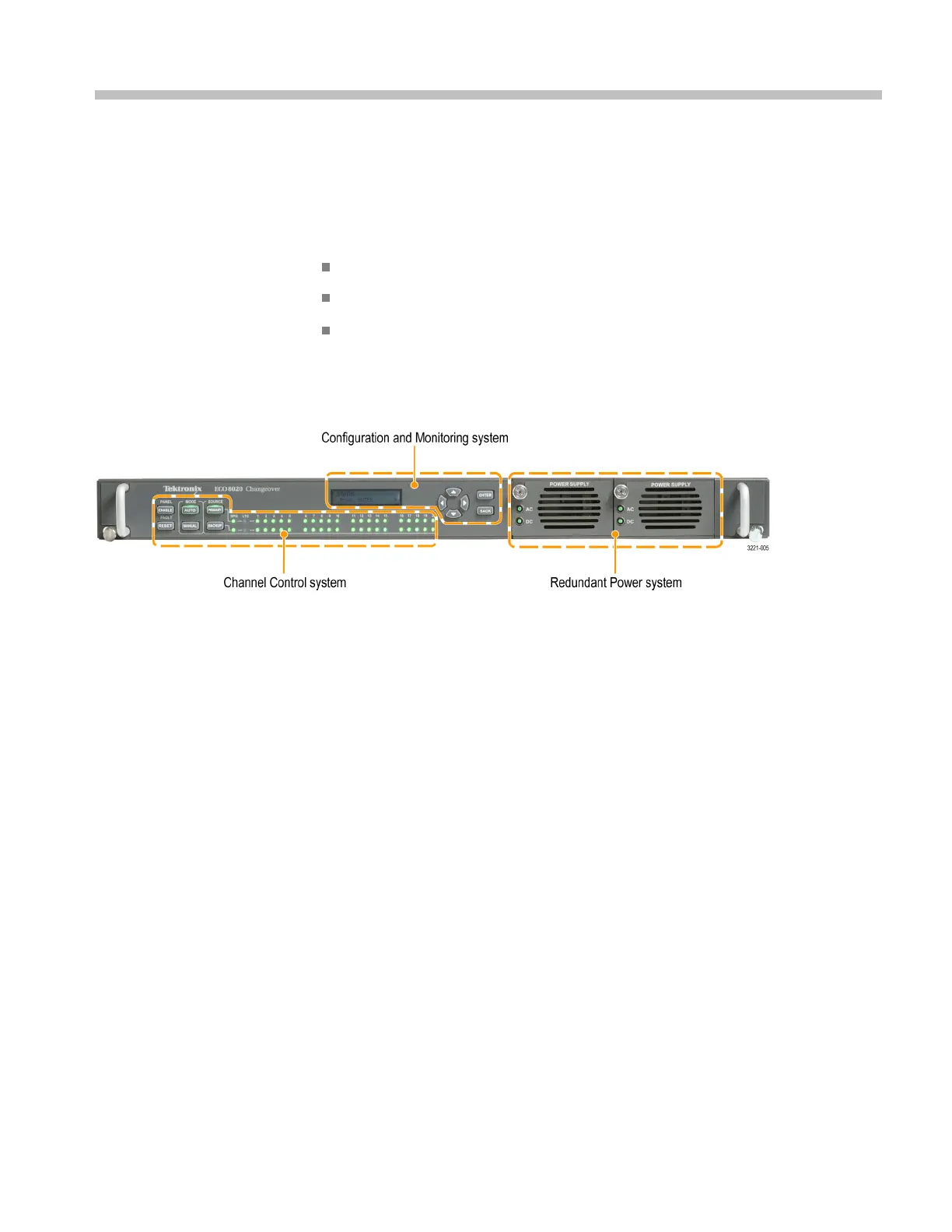

The ECO8000 Series has three main subsystems:

Channel Control system

Configuration and Monitoring system

Redundant Power system

These thre

e subsystems are loosely coupled to assume maximum reliability of the

main ECO function, which is sensing faults on the input signals and switching to

a backup if necessary.

Figure 5: ECO8000 Series subsystems (ECO8020 with Option DPW shown)

Channel Control system

The Channel Control system monitors the level on each input, and switches to the

other sync source if a fault occurs. This subsystem is implemented as a simple

hardware state m achine to maximize reliability. This portion of the instrument is

accessed via the left keyboard, and the status is displayed on the button lights and

the per-channel LEDs on the front panel.

If the instrument is in A UTO mode, then the Channel Control system locks out

any changes from the other subsystems. This prevents most issues in the other

su

bsystems from impacting the basic operation of the ECO.

When the instrument powers on, the Channel Control system restores all basic

c

onfiguration settings that were in place wh en the instrument was powered off.

This restoration i s independent of the processor booting to run the display and

the Configuration and Monitoring system. If the Configuration and Monitoring

system is rebooted, the Channel Control system is unaffected.

If the instrument loses power, the REF/ELSW channels will automatically switch

from electronic to relay mode to maintain the s ignal throughput. These channels

will automatically switch back to electronic mode when power is restored. When

the REF/ELSW channels switch from electronic mode to relay mode and back,

the sync on these channels will experience a momentary glitch.

ECO8000 Series Automatic Changeover Unit User Manual 17

Loading...

Loading...