PAK 200

OPERATION 4-8 Manual

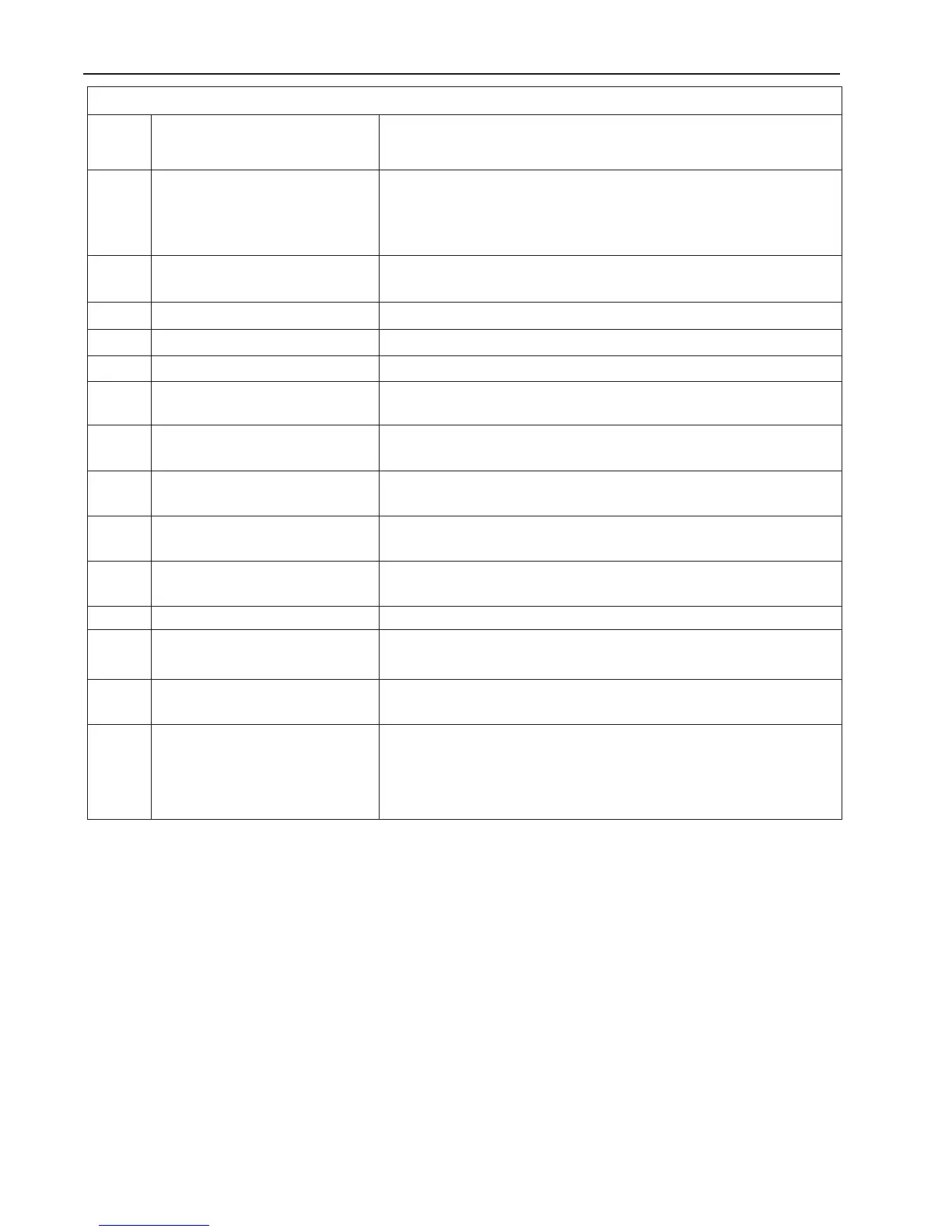

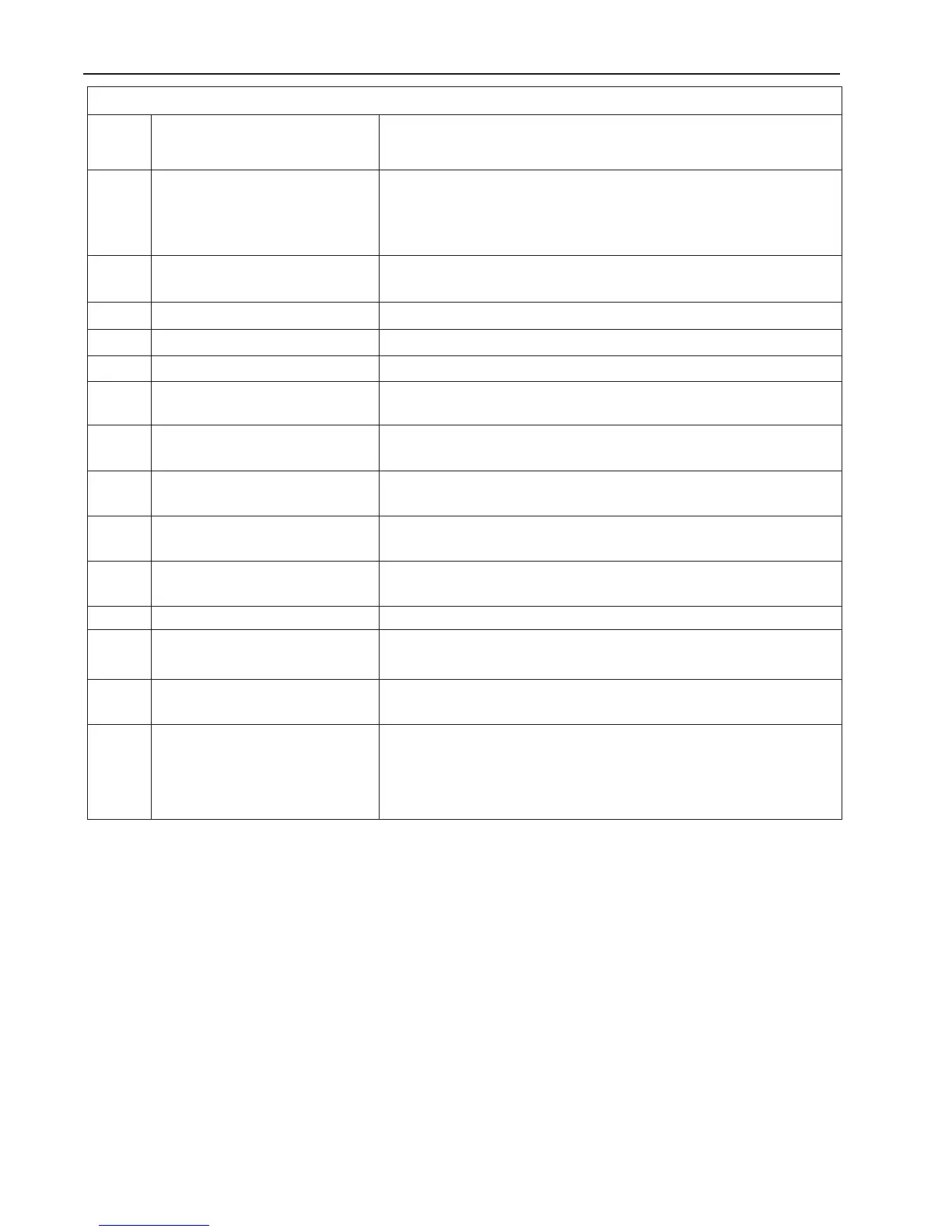

Status Code Key (cont.)

Status

Code

Message Cause/Remedy

3-1

Gas Control Communication

fault, Cannot establish Commu-

nication with gas control.

GCM 200 Control cable not connected or Basic ID signal open;

CCM not PAK 200 (SW13-1 should be off) or

CCM defective, replace.

3-2

Gas Control Communication

reply fault,

Does not apply to PAK200, if displayed CCM defective.

3-3 Gas Pressure Low Plasma < 51 PSI; faulty or disconnected pressure SW.

3-4 Gas Control not ready Purging; RUN/SET in SET position;

3-5 Gas Control Protocol Fault Does not apply to PAK200, if displayed CCM defective.

3-6

Invalid Current Control level

from GCM

Does not apply to PAK200, if displayed CCM defective.

3-7

Gas Control returns wrong com-

mand sequence

Does not apply to PAK200, if displayed CCM defective.

3-8

CCM and Gas Control type (Au-

tocut-Ultracut) mismatch

CCM not PAK200 (SW13-1 should be off) or CCM defective.

3-9

Gas Control Communication

reply fault

Does not apply to PAK200, if displayed CCM defective.

3-10

Warning. -- Gas Control firm-

ware needs update

Does not apply to PAK200, if displayed CCM defective.

4-1 Coolant Level low fault Check coolant level, add as needed.

4-2

Low coolant flow after power on

purge. < 0.4gal/min;

Suction leak introducing air into coolant, suspect rear panel filter

seal; clogged filter; defective pump.

4-3

Coolant overheated (>70

deg. C, 158 deg F)

Coolant fan failed; radiator fins clogged with dirt; Ambient tempera-

ture > 40 deg C.

4-4

Coolant System not ready.

During power on purge / prim-

ing, flow did not reach 0.4 gal/

min for at least 5 seconds

If new installation recycle power to restart pump, may take a few

times to fill hoses;

Damaged torch coolant tube; Suction leak introducing air into cool-

ant, suspect rear panel filter seal; clogged filter; defective pump.

Loading...

Loading...