Greensmaster 3250--DHydraulic System Page 4 -- 76

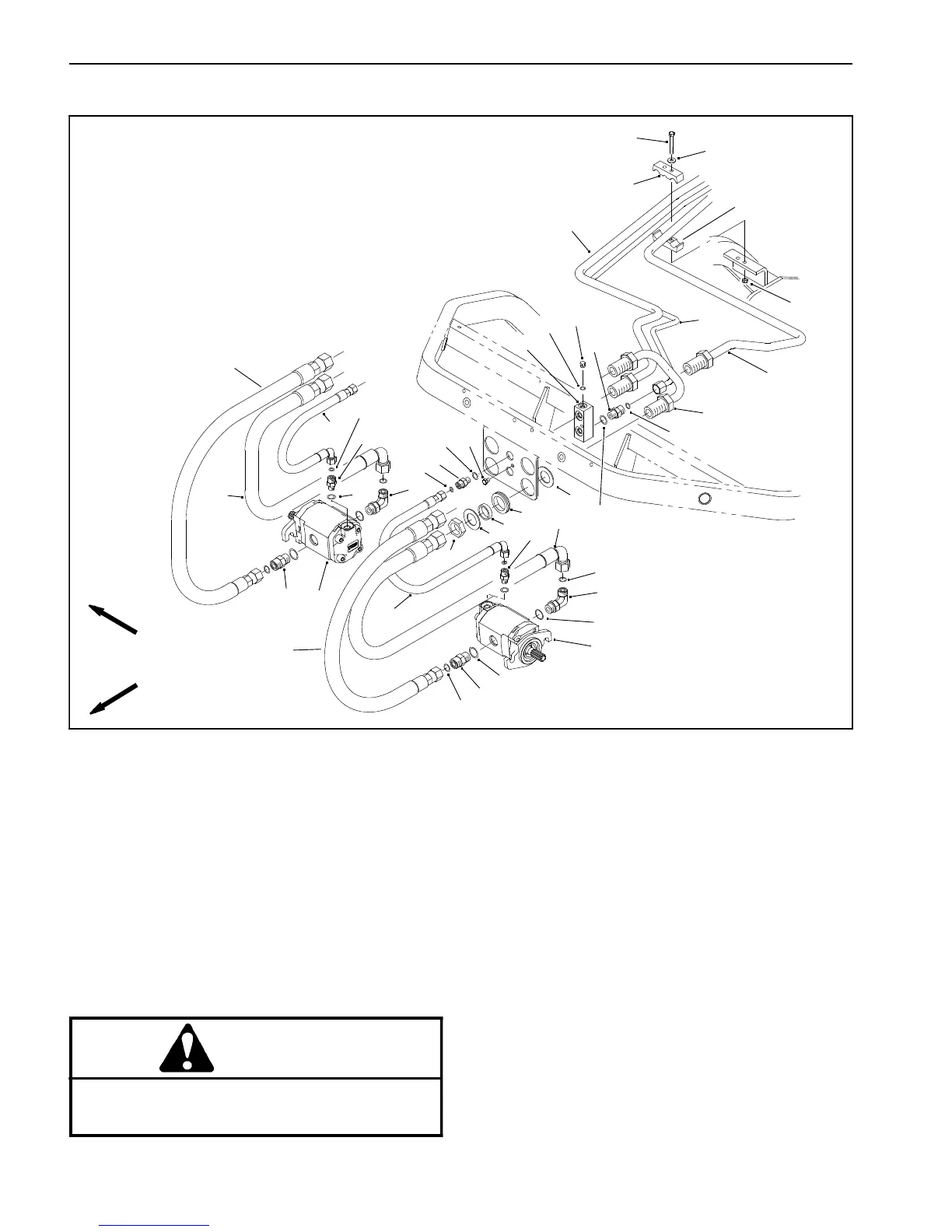

Cutting Reel Motors

1. Cap screw

2. Flat washer

3. Tube clamp

4. Lock nut

5. Plug

6. 90

o

Hydraulic fitting

7. Hydraulic fitting

8. Hydraulic fitting

9. O--ring

10. Bulkhead nut

11. Washer

12. Spacer

13. Reel motor

14. Hose assembly

15. Hose assembly

16. Hydraulic fitting

17. Hose assembly

18. T--block

19. Cap screw

20. Hydraulic tube

21. Hydraulic tube

22. Hydraulic tube

23. Hydraulic tube

24. Rubber grommet

25. O--ring

26. O--ring

27. O--ring

28. O--ring

29. O--ring

30. O--ring

Figure 50

4

20

23

22

21

16

5

18

15

14

17

7

6

8

13

7

12

19

24

10

11

11

7

17

6

13

8

14

15

1

3

2

3

25

26

27

28

28

27

30

29

30

29

9

FRONT REEL MOTORS

FRONT

RIGHT

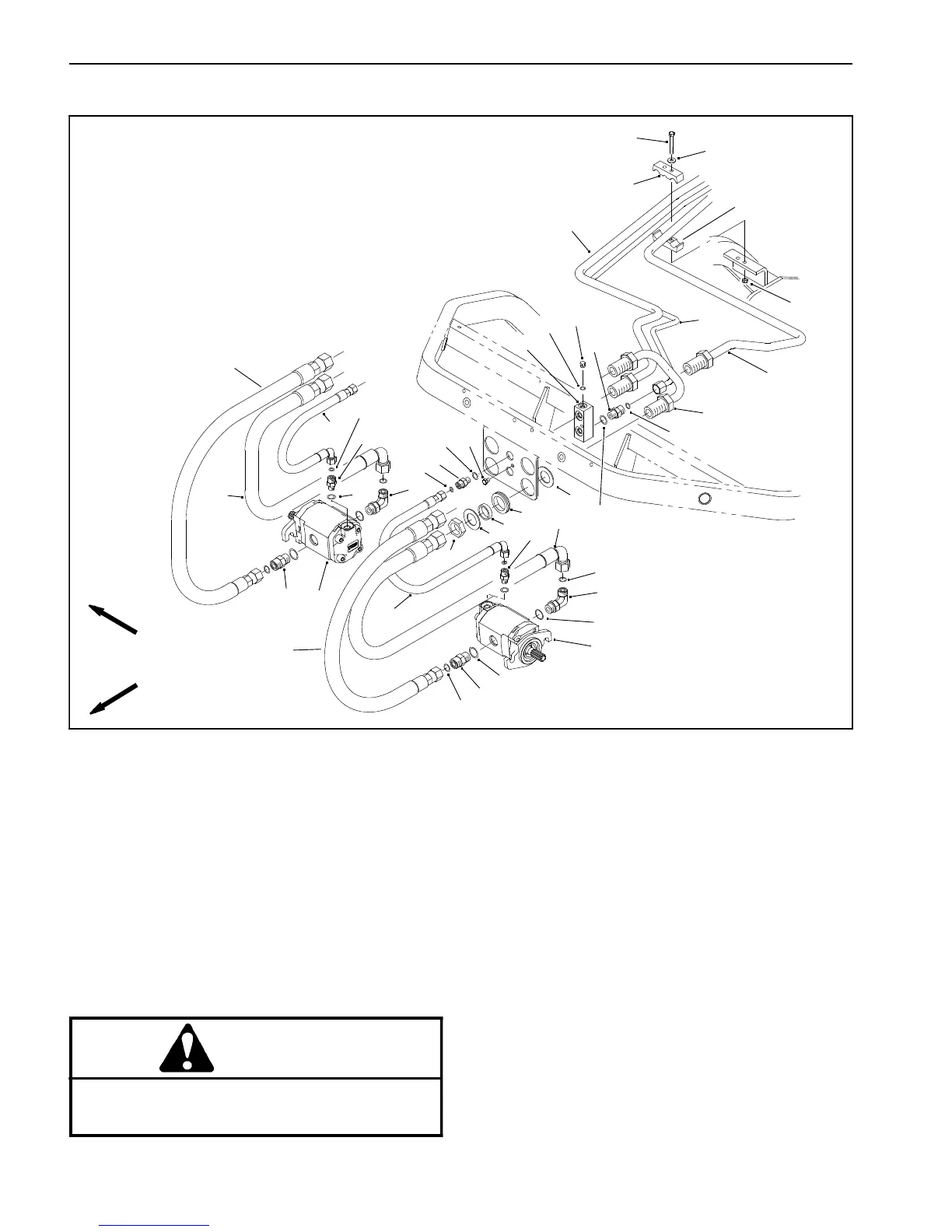

Removal (Figs. 50 and 51)

1. Park the machine on a level surface, engage the

parking brake, lower the cutting units and stop the en-

gine. Remove key from the ignition switch.

CAUTION

Before continuing further, read and become fa-

miliar with General Precautions for Removing

and Installing Hydraulic System Components.

2. Label hydraulic hoses for assembly purposes.

3. Disconnect hydraulic hoses from fittings on the reel

motor. Allow hoses to drain into a suitable container.

Caporplughosesandmotorfittingstopreventcontami-

nation.

4. Loosen two (2) cap screws that secure the hydraulic

reel motor to t he cutting unit side plate. Rotate motor

clockwise and remove motor from cutting unit.

NOTE: Thepositionofhydraulicfittings on the reel mo-

tor is critical to properly connecting hydraulic hoses.

Loading...

Loading...