Greensmaster 3250--D Page 3 -- 1 5 Diesel Engine

Engine Removal (Fig. 12)

1. Park machine on alevelsurface,lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

CAUTION

The engine, radiator, exhaust system and hy-

draulic system may be hot. To avoid possible in-

jury,allowmachinetocoolbeforeworkingonthe

engine.

2. Close fuel shut--off valve on fuel tank.

3. Remove air cleaner and air intake hose from ma-

chine (see Air Cleaner in this section).

4. Remove radiator from machine (see Radiator in this

section).

5. Remove exhaust system from machine (see Ex-

haust System in this section).

6. Disconnect fuel supply hose from the injector pump

andfuelreturnhosefromthe#3 injector (Fig. 13). Drain

any fuel trapped in the hoses into a suitable container.

Plughosesandpositionthemawayfromengineassem-

bly.

7. Loosenscrewthatsecuresthethrottlecabletoswiv-

el on injector pump speed control lever. Disconnect

cable from swivel and cable bracket (Fig. 14). Position

cable away from engine.

8. Disconnect wire harness c onnectors from engine

components:

NOTE: Beforedisconnectingwireharnessconnectors,

label all electrical leads for assembly purposes.

A. Negative battery cable (item 4) and wireharness

ground (item 2) that are secured to the engine at the

lift hook above the bell housing.

B. Fuel solenoid (Fig. 13).

C. Glow plug bus (Fig. 13).

D. Temperature sender (Fig. 15).

E. Alternator connector and stud (Fig. 15).

F. Starter motor solenoid and fusible link harness

(Fig. 15).

G. Oil pressure switch (near oil filter) (Fig. 15).

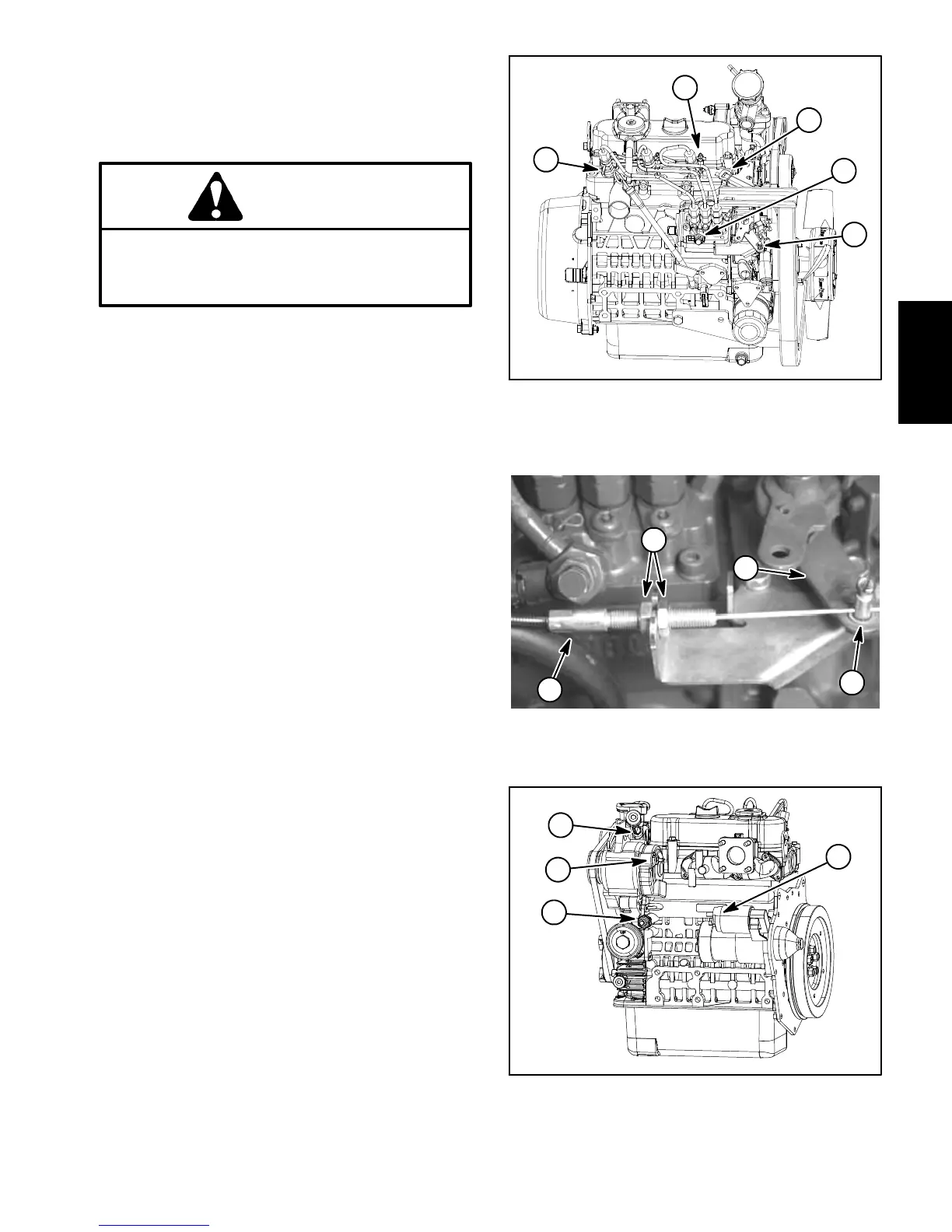

Figure 13

1. Fuel return fitting

2. Throttle cable swivel

3. Fuel supply fitting

4. Glow plug bus

5. Fuel solenoid

1

2

4

3

5

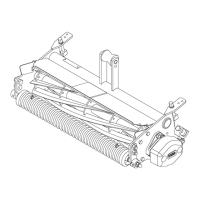

Figure 14

1. Throttle cable

2. Speed control lever

3. Cable jam nut

4. Throttle cable swivel

4

2

1

3

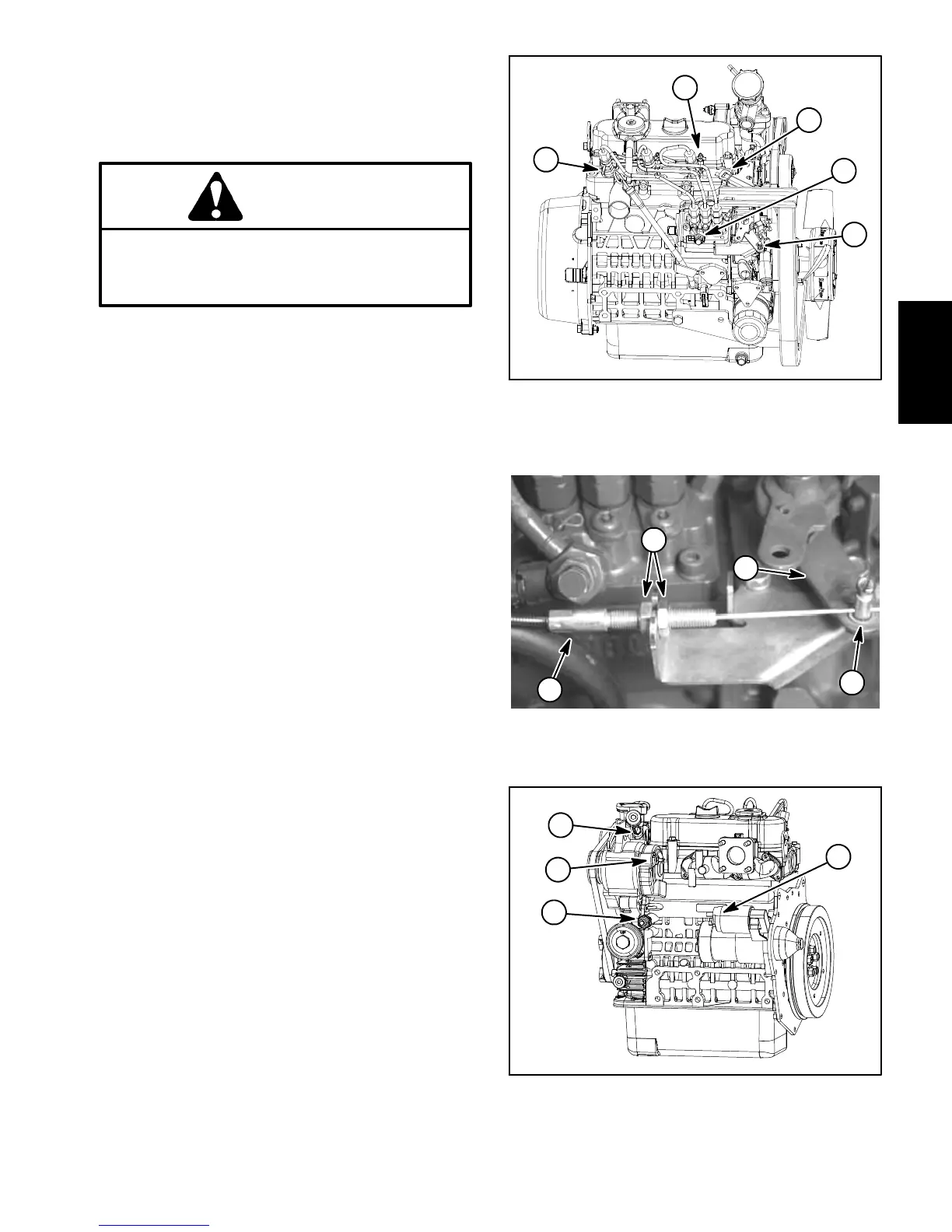

Figure 15

1. Temperature sender

2. Alternator stud

3. Oil pressure switch

4. Starter solenoid

1

2

3

4

Engine

Diesel

Loading...

Loading...