Greensmaster 3250--DPage 3 -- 18Diesel Engine

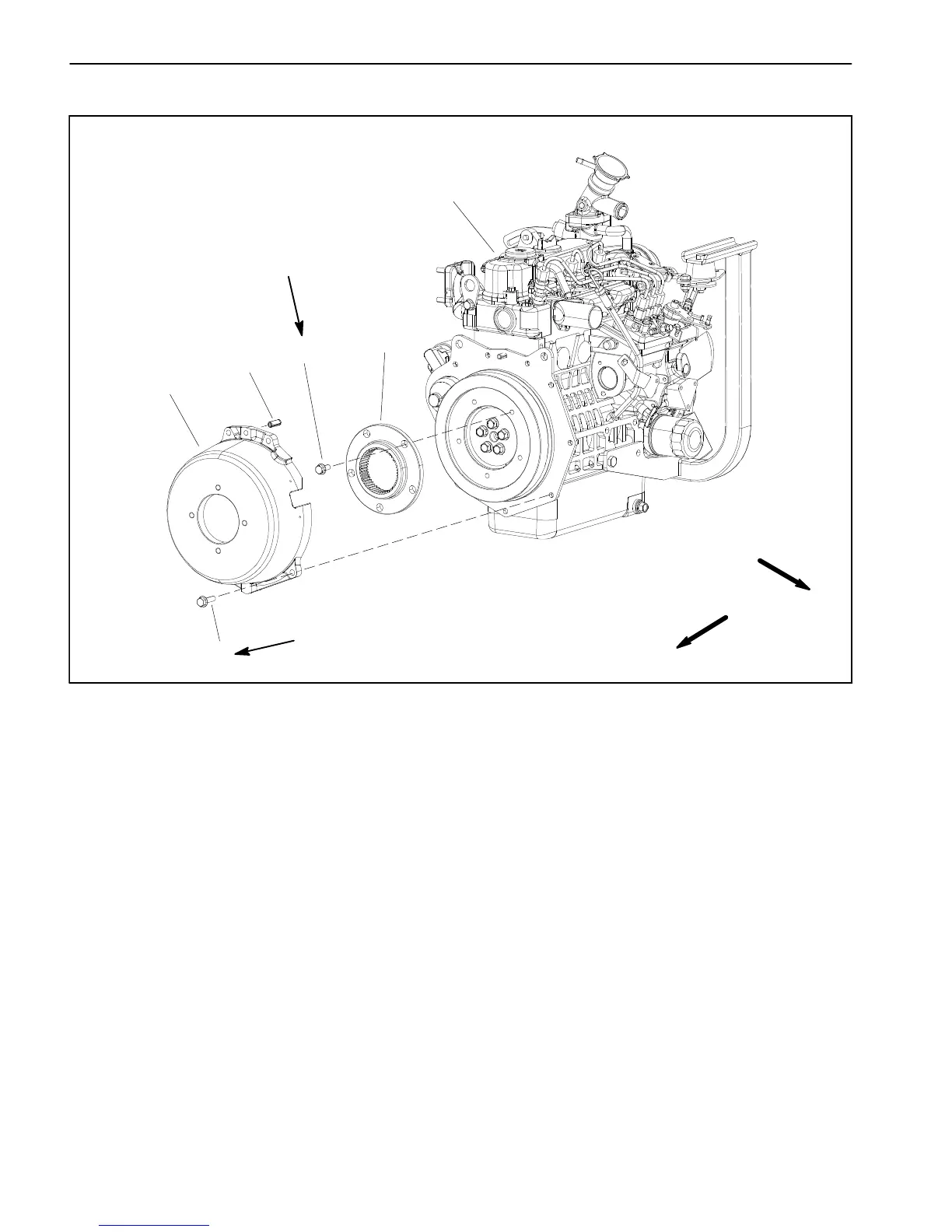

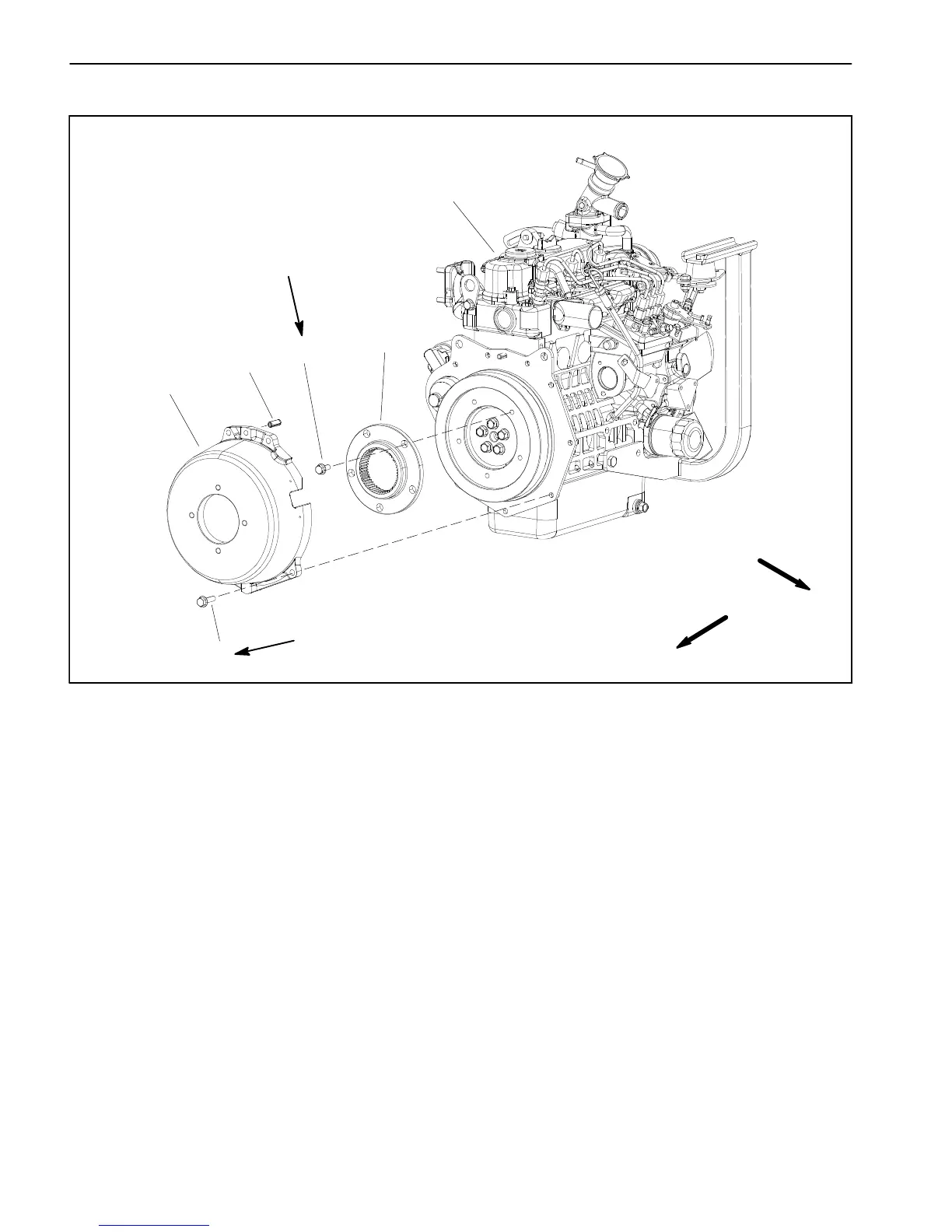

Engine Bell Housing

Figure 17

1. Engine

2. Flange head screw (5 used)

3. Bell housing

4. Coupling flange

5. Flange head screw (4 used)

6. Spring pin

FRONT

RIGHT

5

3

4

2

1

6

17 to 21 ft--lb

(23to28N--m)

Loctite #242

17 to 21 ft--lb

(23to28N--m)

Loctite #242

Removal (Fig. 17)

NOTE: The hydraulic pump assembly needs to be re-

moved from engine before bell housing and coupling

flange can be removed.

1. Ifengineisinmachine,supportenginefrombelowto

preventitfromshifting.Removehydraulicpumpassem-

bly(seePiston(Traction) Pump Removal in the Service

and Repairs section of Chapter 4 -- Hydraulic System).

2. As necessary, remove bell housing and coupling

flange from engine using Figure 17 as a guide.

Installation (Fig. 17)

1. If coupling flange was removed from engine fly-

wheel, position flange to flywheel and align mounting

holes. Apply Loctite #242 to threads of flange head

screws(item2). Securecouplingflangetoflywheelwith

five(5)flangeheadscrews.Tightenscrewsinastarpat-

tern to a torque 17 to 21 ft--lb (23 to 28 N--m).

2. Ifbellhousingwasremovedfromengine,makesure

that spring pin is secure in upper hole of bell housing.

Apply Loctite #242 to threads of flange head screws

(item 5). Position bell housing to flywheel plate and se-

curewith five (5) flange head screws.Tighten screws in

a star pattern to a torque 17 to 21 ft--lb (23 to 28 N--m).

3. If engine is in machine, install hydraulic pump as-

sembly (see Piston (Traction) Pump Installation in the

Service and Repairs section of Chapter 4 -- Hydraulic

System).

Loading...

Loading...