Greensmaster 3250--DHydraulic System Page 4 -- 32

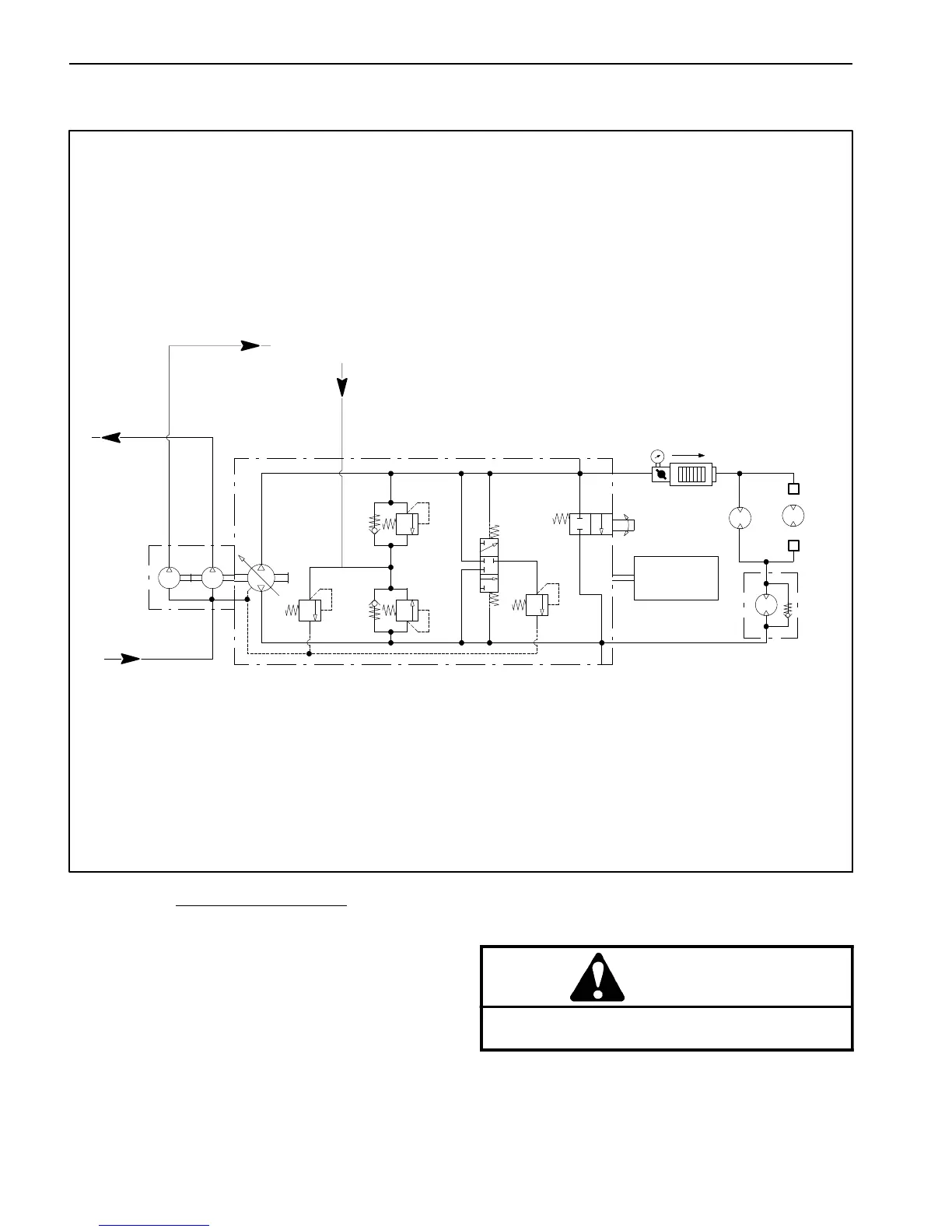

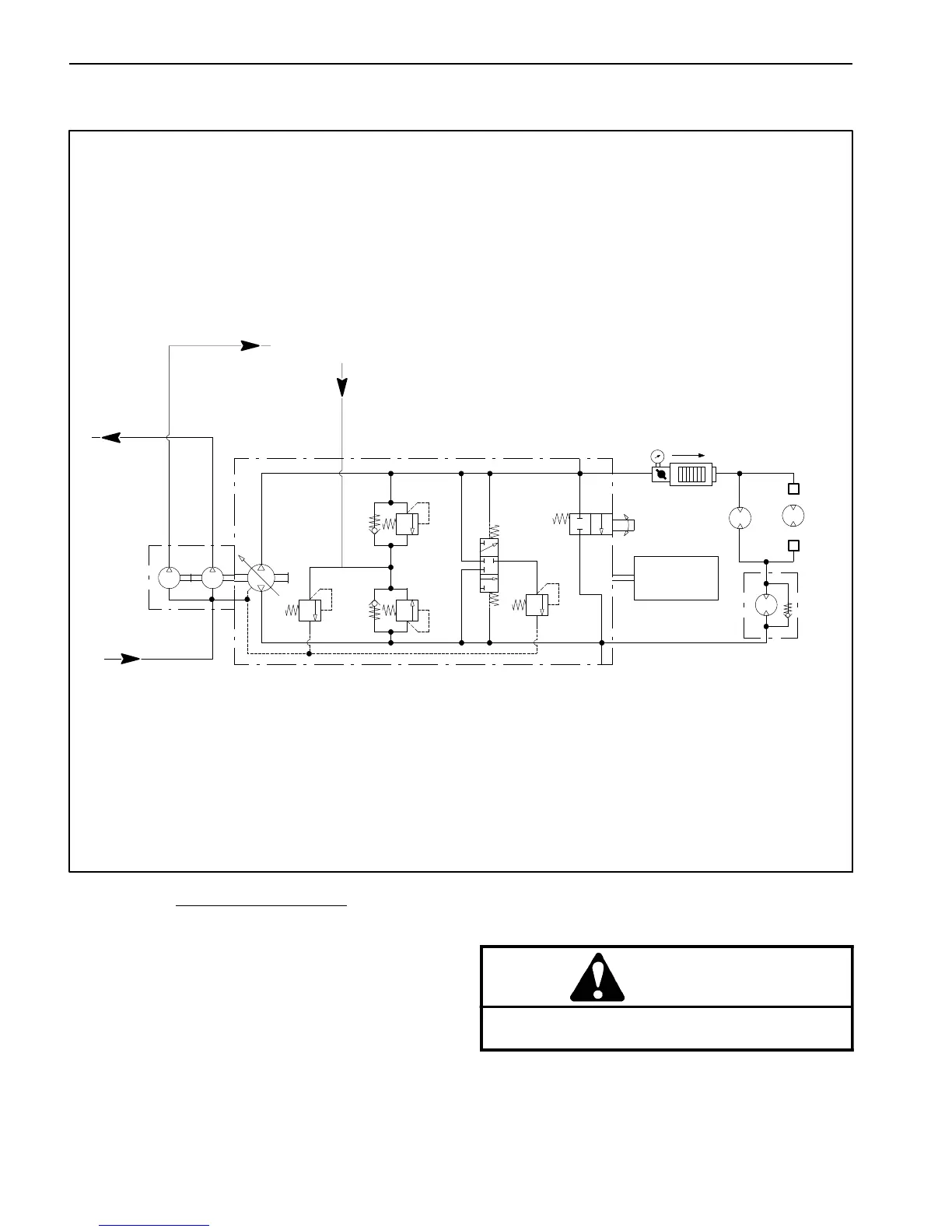

Wheel Motor Efficiency Test (Using Tester with Flowmeter and Pressure Gauge)

.33 .58

70--100

PSI

3000 PSI

110--150

PSI

ENGINE RPM

2710/1500

BOTTOM

PORT

TOP

PORT

B

A

TRACTION PUMP

OPTIONAL

GEAR

PUMP

LEFT

RIGHT

MOTOR

3WD KIT

MOTOR

BYPASS

VALVE

3000 PSI

1.24

10.3

20.6

10.3

FROM CONTROL

TESTER

TO STEERING

VALVE

MANIFOLD PORT PT

TO CONTROL

MANIFOLD

PORT P1

FROM HYDRAULIC

RESERVOIR

CAP

CAP

ILLUSTRATION SHOWS TEST

FOR LEFT FRONT MOTOR

Procedure for Wheel Motor Efficiency Test

NOTE: Over a period of time, a wheel motor can wear

internally. A worn motor may by--pass oil causing the

motortobelessefficient.Eventually,enoughoillosswill

cause t he wheel motor to stall under heavy load condi-

tions.Continuedoperationwith aworn,inefficientmotor

cangenerateexcessiveheat,causedamagetoseals

and other components in the hydraulic system and af-

fect overall machine performance.

1. Make sure hydraulic oil is at normal operating tem-

peraturebyoperatingthemachineforapproximatelyten

(10) minutes. Make sure the hydraulic tank is full.

2. Parkmachineonalevelsurfacewiththecuttingunits

lowered and off. Make sure engine is off.

CAUTION

Before continuing further, read and become f a-

miliar with Precautions for Hydraulic Testing.

3. Make sure that traction pedal is adjusted to the neu-

tral position (see Traction Unit Operator ’s Manual).

Loading...

Loading...