Greensmaster 3250--D Hydraulic SystemPage 4 -- 3 3

4. Attachaheavychaintotherearofthemachineframe

and an immovable object to prevent the machine from

moving during testing.

5. Ifmachinehas3wheeldrive,blockuptherearwheel

offthegroundtoallowflowthroughtherearwheelmotor.

6. Chock front wheelbeingtestedto prevent rotation of

the wheel.

7. Thoroughly clean junction of hydraulic lines and fit-

tings at the front wheel motor that is not being tested.

Disconnect hydraulic lines from front wheel motor that

is not being tested. Cap the disconnected hydraulic

lines and plug ports in wheel motor.

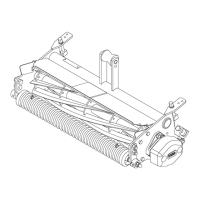

8. Thoroughly clean junction of hydraulic hose and the

upper hydraulic fitting on the front side of the piston

pump(Fig.19).Disconnecthosefromtheupperhydrau-

lic fitting.

9. Install tester with pressure gauge and flow meter in

series with the pump and the disconnected hose (same

tester connections as Piston (Traction) Pump Flow

Test). Make sure the tester flow control valve is fully

open.

CAUTION

Use extreme caution when performing test. The

wheel being tested will be trying to move the ma-

chine.

10.Start engine and move throttle to high idle speed

(2710 +

50 RPM).

11.Slowly push traction pedal in forward direction until

1000 PSI (69 bar) is displayed on the t ester pressure

gauge.

12.Wheel motor internal leakage will be shown on flow

meter in GPM. Flow should be less than 1.5 GPM for

the tested wheel motor.

13.Release traction pedal, rotate wheel being tested

and retest. Testing of wheel motor leakage in three (3)

differentwheel positions will provide m ost a ccurate test

results.

14.Release traction pedal and shut engine off. Record

results of flow test.

15.If specification is not met, the tested wheel motor

needs to be repaired or replaced as necessary.

16.Test second front wheel motor. Reconnect hydraulic

linesto untested front wheel motor.Disconnectand cap

hydraulic lines to tested front wheel motor. Complete

steps 10 to 15 for the second front wheel motor.

17.If machine has 3 wheel drive, test rear wheel motor:

A. Both front wheel motors should have hydraulic

lines connected. Block up both front wheels off the

ground.

B. Attach a heavy chain to the rear of the machine

frame and an immovable object to prevent the ma-

chine from moving during testing.

C. Positionrearwheelonthegroundandchockrear

wheel to prevent it from turning.

CAUTION

Use extreme caution when performing test. The

rear wheel will be trying to move t he machine.

D. Complete steps 10 to 15.

NOTE: The Piston (Tr action) Pump Flow Test uses the

same tester connections as this wheel m otor efficiency

test. If necessary, perform the piston pump flow test be-

fore removing the tester from the machine.

18.When wheel motor testing is completed, disconnect

tester from hydraulic fitting and hose. Reconnect hose

to piston pump fitting.

1. Piston pump 2. Upper hydraulic hose

Figure 19

2

1

Hydraulic

System

Loading...

Loading...