Greensmaster 3250--D Hydraulic SystemPage 4 -- 5 3

Flush Hydraulic System

IMPORTANT: Flush the hydraulic system any time

thereis asevere component failure ort he systemis

contaminated (oil appears milky or black or con -

tains metal particles).

IMPORTANT: Flush hydraulic system when chang -

Ing from petroleum base hydraulic fluid. Operate

machine under normal operating conditions for at

least four (4) hours before draining.

1. Park the machine on a level surface, engage the

parking brake, lower the cutting units and stop the en-

gine. Remove key from the ignition switch.

CAUTION

Before continuing further, read and become fa-

miliar with General Precautions for Removing

and Installing Hydraulic System Components.

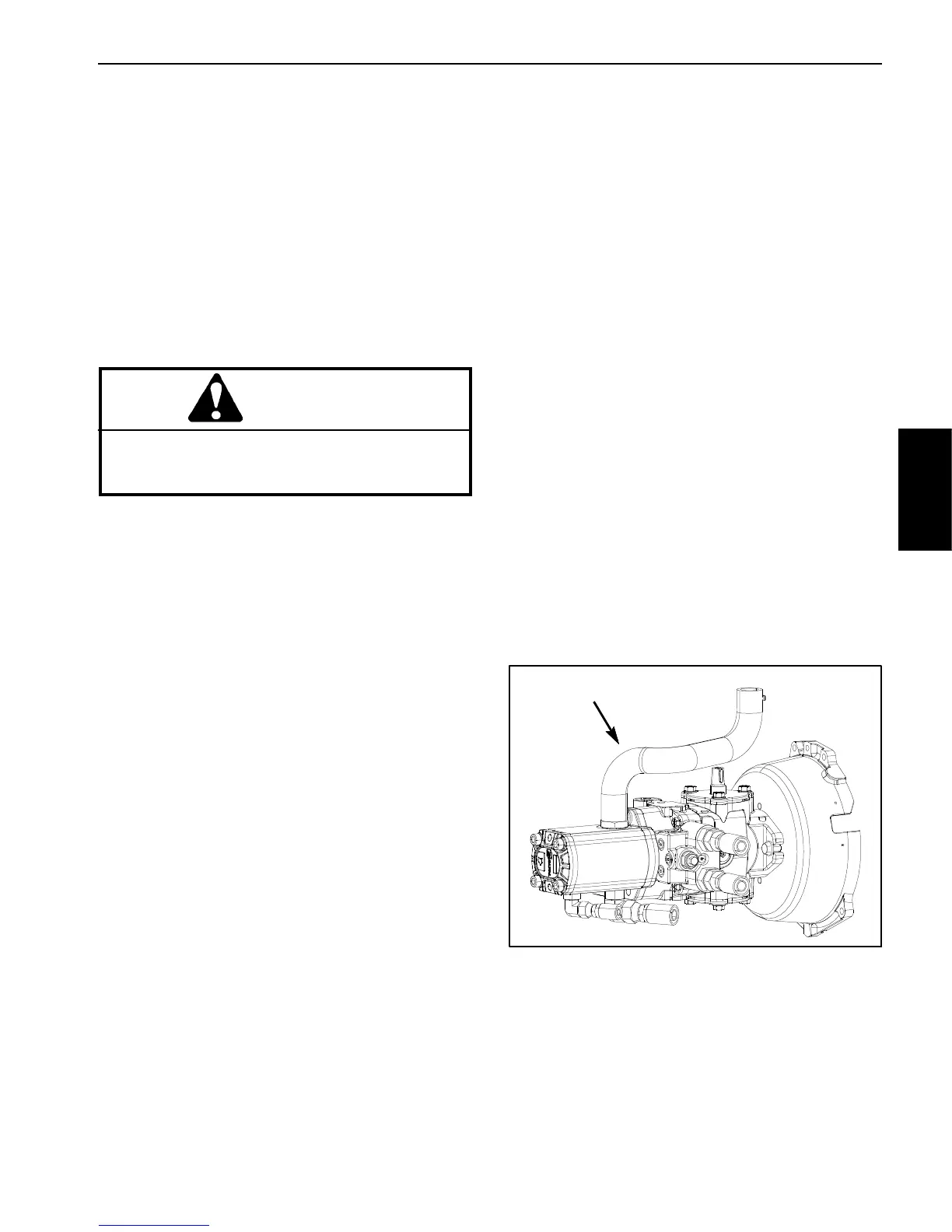

2. Cleanareaaroundpistonpumpandpumpinlethose

(Fig. 31). Clamp pump inlet hose. Remove hose from

piston pump, release clamp and drain reservoir into a

suitablecontainer. Drain hydraulicsystem whilemaking

sure lift cylinders, hydraulic hoses, hydraulic tubes and

all other components are drained from low points while

the system is warm.

3. Clean hydraulic oil filter mounting area. Remove fil-

ter and drain into a suitable container. Discard filter.

4. Inspect and clean hydraulic reservoir (see Hydraulic

Reservoir in the Service and Repairs section of this

chapter).

5. Make sure filter mounting surface is clean.Applyhy-

draulic oil to gasket on the newfilter. Screwfilter on until

gasket contacts mounting plate, then tighten filter 3/4

turn further.

NOTE: Use only hydraulic fluids (including biodegrad-

able) specified in t he Traction Unit Operator’s Manual.

Other fluids could cause system damage.

6. Reconnect all hydraulic hoses and lines that were

disconnected prior to draining. Fill hydraulic reservoir.

7. Disconnect electricalconnector to the fuel stop sole-

noid to prevent engine from starting on diesel engine.

8. Turn ignition key switch; engage starter for ten (10)

seconds to prime the hydraulic pumps. Allow thestarter

to cool for sixty (60) seconds and then repeat this step

again.

9. Connect electrical connector to the fuel stop sole-

noid on diesel engine.

10.Startengineandletitidleatlowspeedforaminimum

oftwo(2)minutes.Increaseenginespeedtohighidlefor

minimum of one (1) minute under no load.

11.Raise and lower cutting units several times.

12.Shut off engine and check for hydraulic oil leaks.

Check oil level in hydraulic reservoir and add correct oil

if necessary.

13.Operate themachine for two (2) hours under n ormal

operating conditions.

14.Check condition of hydraulic oil. If the h ydraulic oil

showsanysignsofcontamination,orify ouarechanging

to biodegradablefluid,repeat steps 1 through13 again.

15.Assume normal operation and follow recommended

maintenance intervals.

Figure 31

PUMP INLET HOSE

Hydraulic

System

Loading...

Loading...