Greensmaster 3250--D

Page 5 -- 10

Electrical System

Electrical System Quick Checks

Battery Test

Use a multimeter to measure the voltage between the

battery terminals.

Set the multimeter to the DC volts setting. The battery

should be at a temperature of 60

o

to 100

o

F(16

o

to 37

o

C). The ignition key should be off and all accessories

turned off. Connect the positive (+) meter lead to the

positivebattery postand thenegative(--)meterleadthe

negative battery post.

NOTE: Thistestprovidesarelativeconditionofthebat-

tery. Load testing of the battery will provide additional

and more accurate information (see Battery Service in

the Service and Repairs section of this chapter).

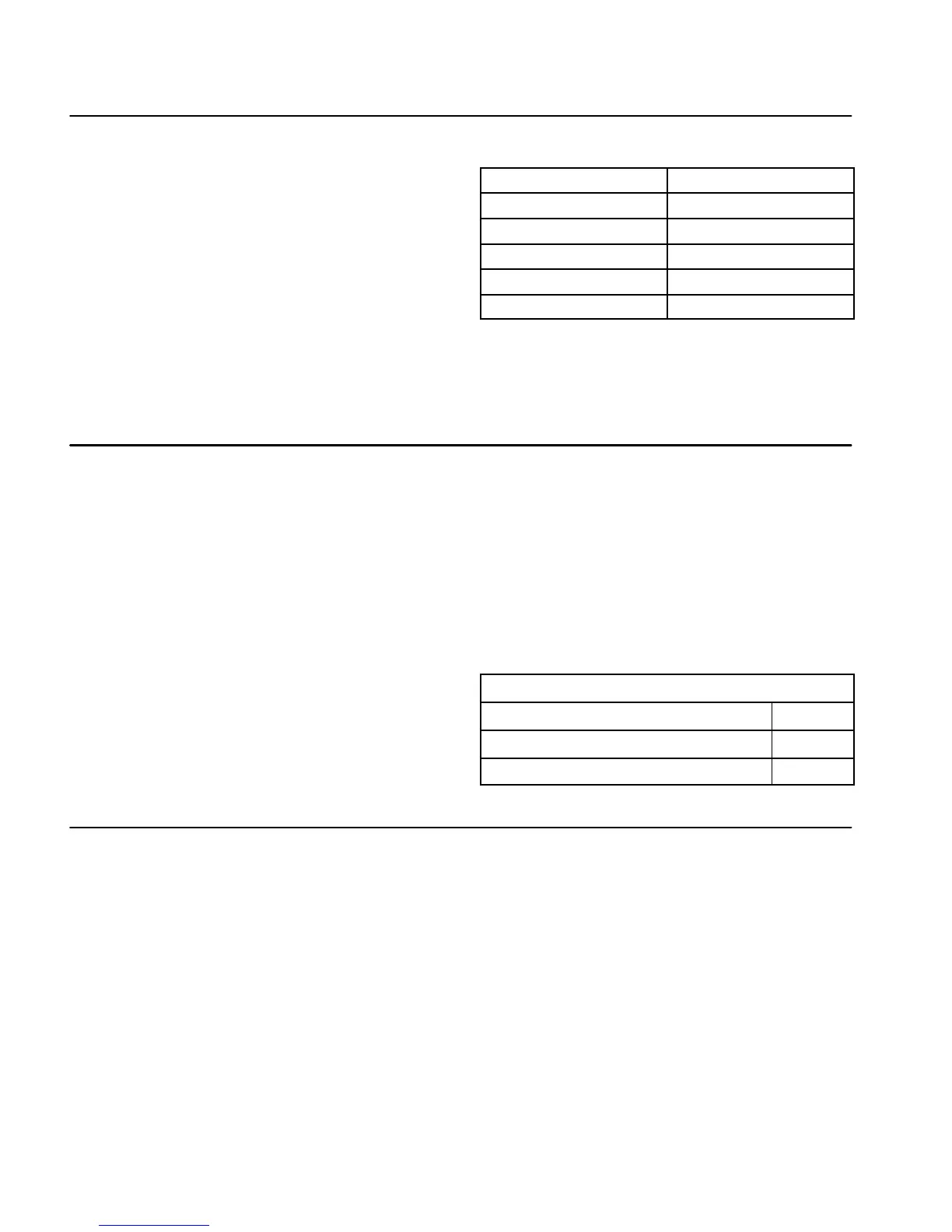

Voltage Measured

Battery Charge Level

12.68 V (or higher) Fully charged (100%)

12.45 V 75% charged

12.24 V 50% charged

12.06 V 25% charged

11.89 V 0% charged

Charging System Test

Thisis asimpletestusedtodetermineifachargingsys-

tem is functioning. It will tell you if the charging system

has an output, but not its capacity.

Use a digital multimeter set to DC volts. Connect the

positive (+) multimeter lead to the positive battery post

andthenegative(--)multimeterleadtothenegativebat-

tery post. Keep the test leads connected to the battery

posts and record the battery voltage.

NOTE: Upon starting the engine, the battery voltage

will drop and then should increase once the engine is

running.

NOTE: Depending upon the condition of the battery

chargeandbatterytemperature,thebatteryvoltagewill

increase at different rates as the battery charges.

Start the engine and run at high idle. Allow the battery

to charge for at least three (3) minutes. Record the bat-

tery voltage.

After running the engine for at least three (3) minutes,

battery voltage should be at least 0.50 volt higher than

initial battery voltage.

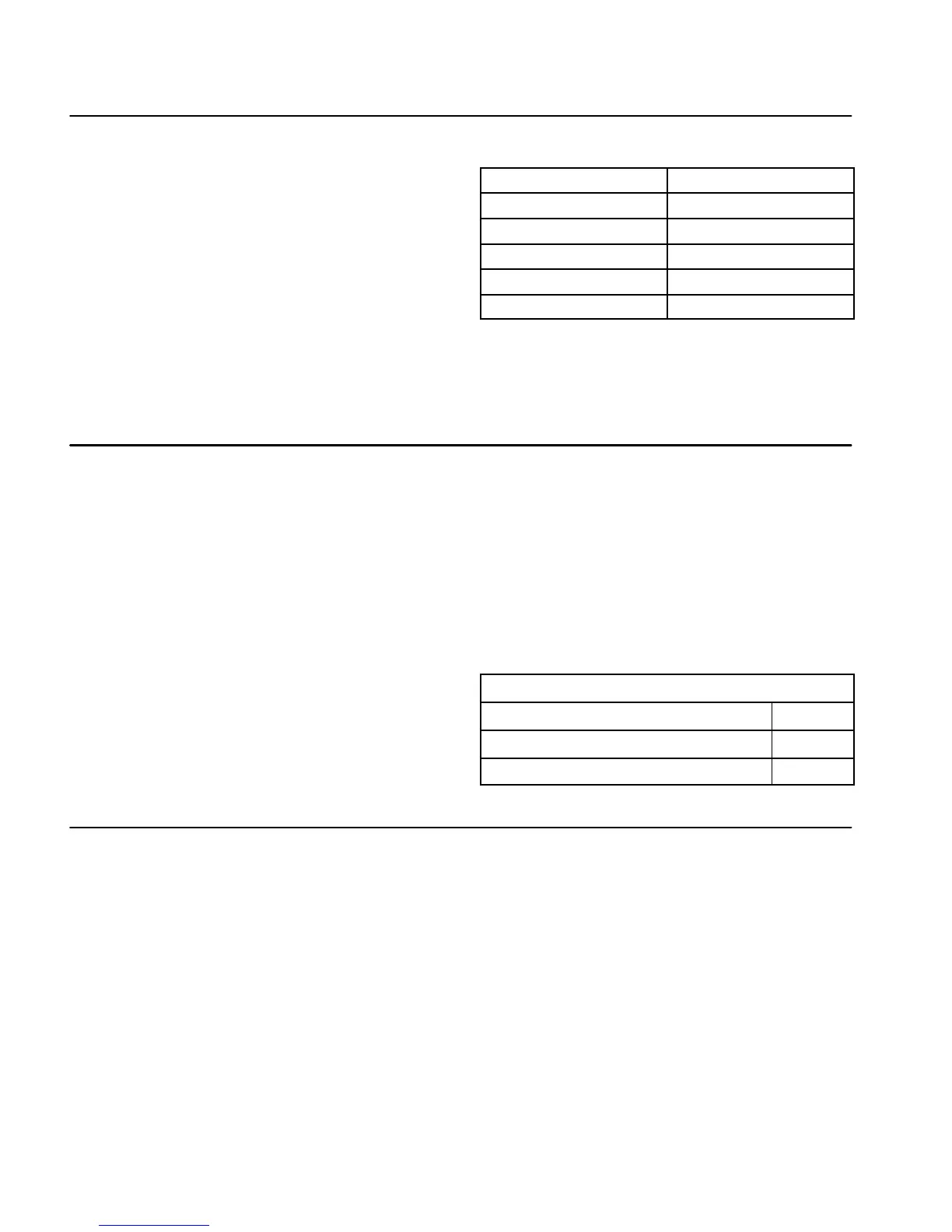

An example of a charging system that is functioning:

At least 0.50 volt over initial battery voltage.

Initial Battery Voltage = 12.30 v

Battery Voltage after 3 Minute Charge = 12.95 v

Difference = +0.65 v

Glow Plug System Test

This is a fast, simple test that can help to determine the

integrity and operation of your Greensmaster 3250--D

glow plug system. The test should be run anytime hard

starting(coldengine) is encounteredonadieselengine

equipped with a glow plug system.

Use a digital multimeter and/or inductive ammeter (AC/

DCCurrentTransducer).Properlyconnecttheammeter

tothe digitalmultimeter (refertomanufacturers’instruc-

tions) and set the multimeter to the correct scale. With

the ignition switch in the OFF position, place the

ammeter pickup around the main glow plug power sup-

ply wire and read the meter prior to activating the glow

plug system. Adjust the meter to read zero (if applica-

ble). Activate the glow plug system by turning the igni-

tion switch to RUN and record the multimeter results.

The Greensmaster 3250--D glow plug system should

have a r eading of approximately 27 amps total (nine (9)

ampsper glow plug). Iflow currentreading is observed,

one (or more) of the glow plugs is faulty.

Loading...

Loading...